AUTOMATIC SYSTEMFOR PRECIOUS METAL INGOT FINISHING AND BRUSHING

T-BRUSH™

AUTOMATIC BRUSHING MACHINE FOR MIRROR FINISH POLISHING OF PRECIOUS METAL INGOTS

Automating the ingot polishing process means optimizing the time required to carry out this operation and improving operators' working conditions. As a matter of fact, brushing machines, which are ever-present in goldsmith companies, require the constant presence of operators, who are exposed to many risks and compelled to carry out a low-skilled task.

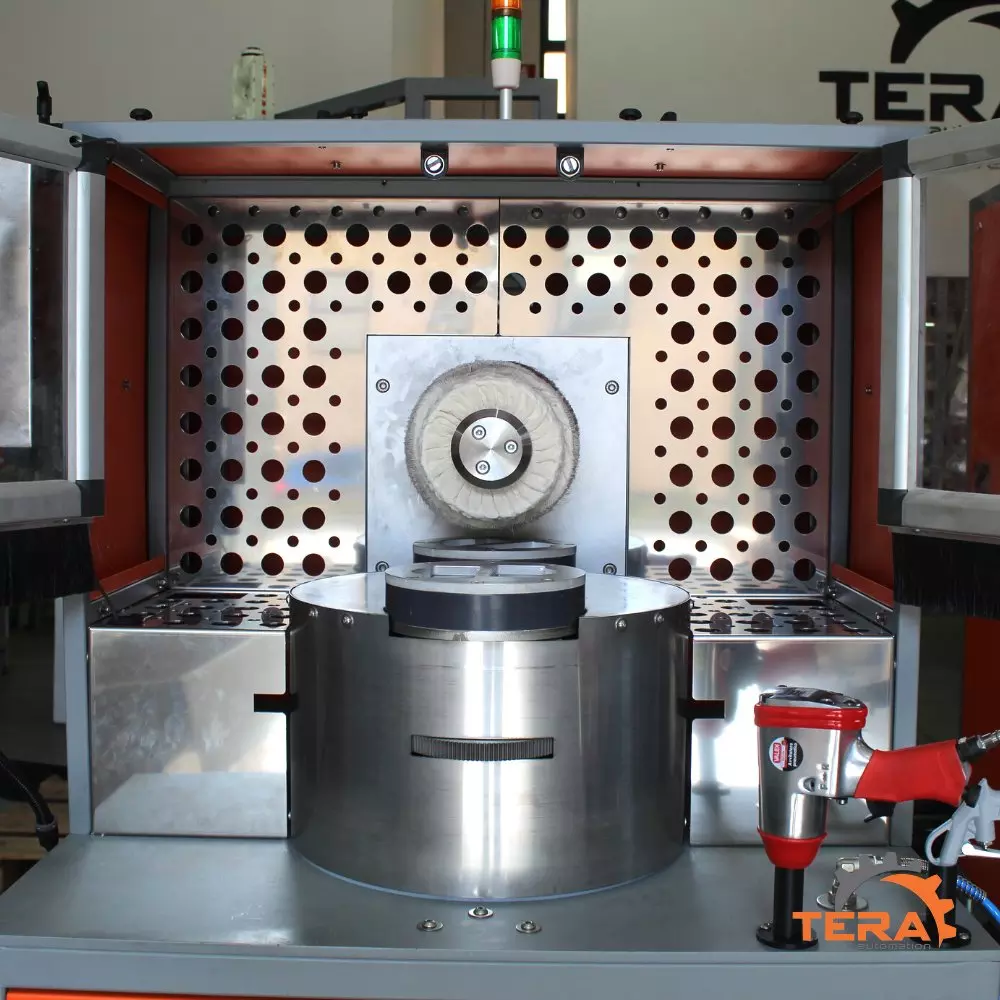

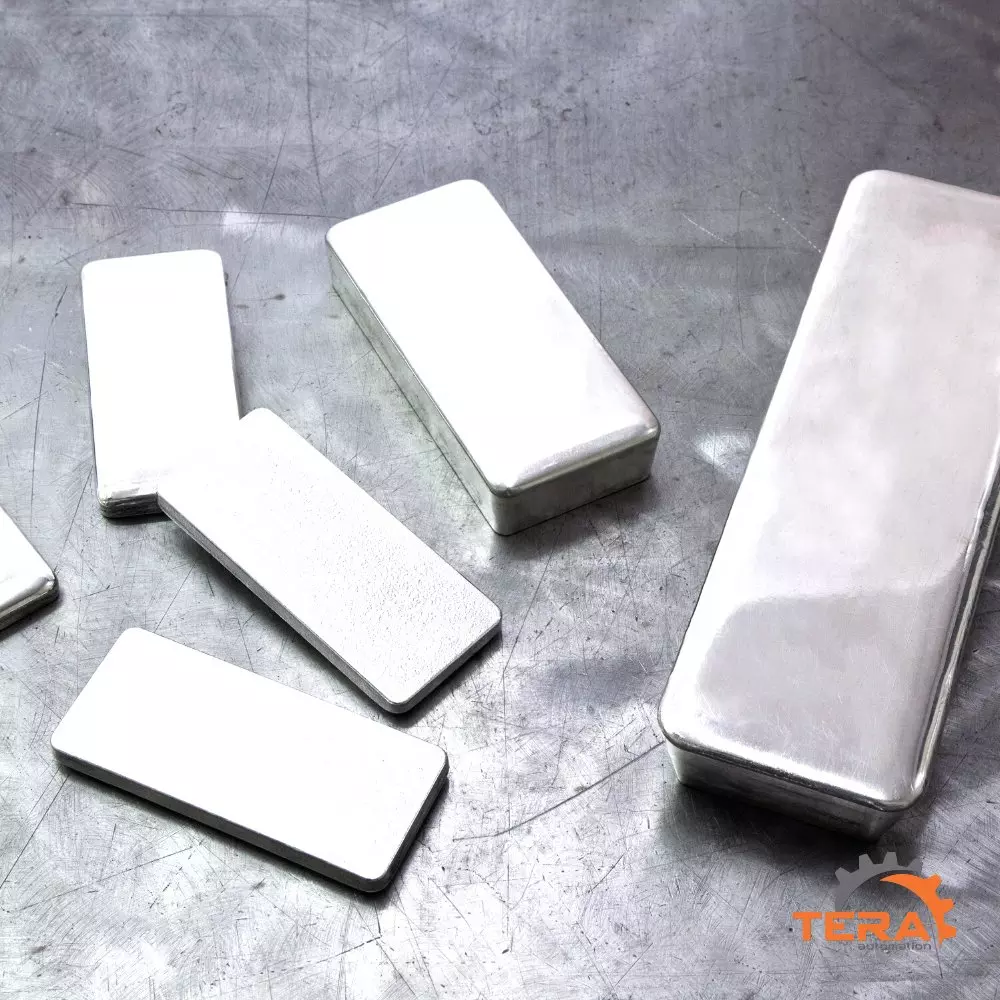

The T-Brush™ machine is designed to automate mirror finish polishing of precious metal ingots.

Our brushing machine is specifically conceived to make sure that operators never touch the brushes. Operators will have to insert the ingots which need to be polished, and extract the polished ones, whenever this task is not carried out by an anthropomorphic robot.

The machine can be set choosing from all its different configurations, according to the size and weight of the ingots that the company wishes to polish.

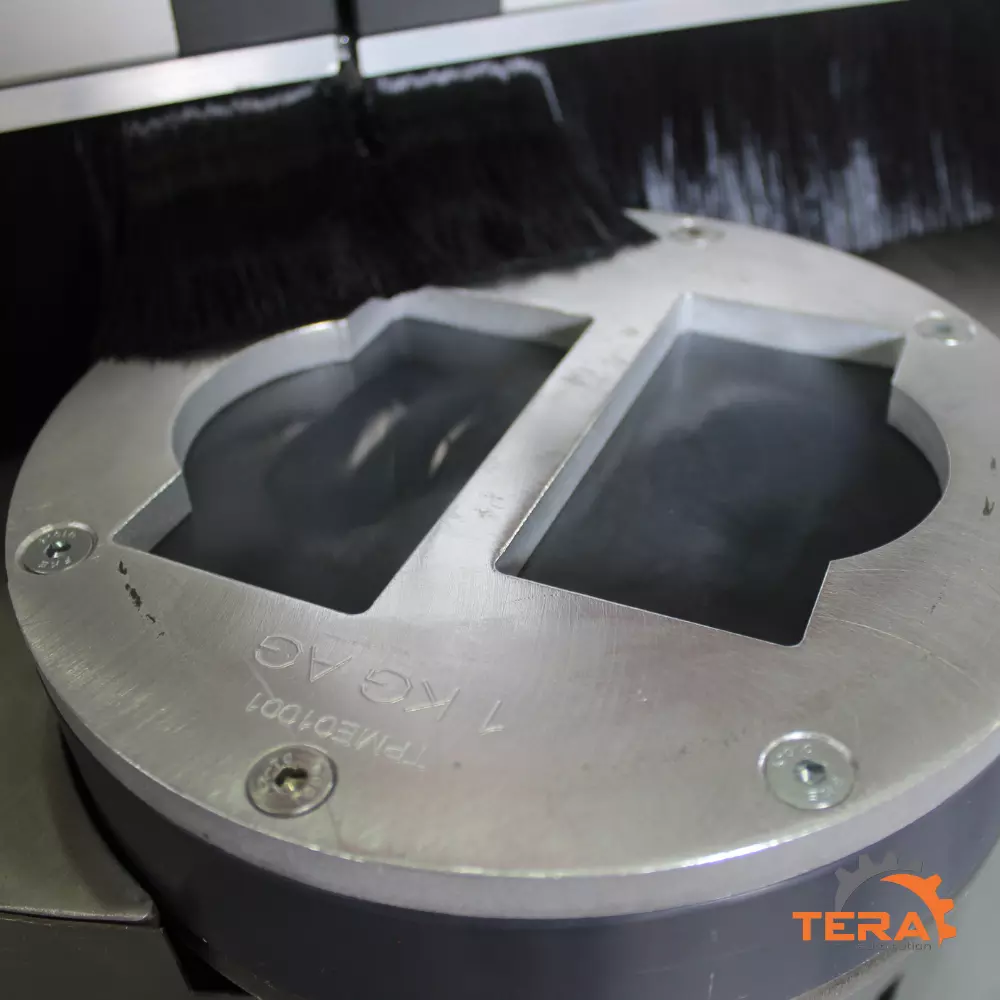

It is equipped with customizable templates and a set of interchangeable brushes.

Because the brushing process generates waste, the T-Brush™ brushing machine is fitted with a suction fan which is also extremely useful to keep the working area hygienic and clean.

T-BRUSH™

IS AVAILABLE AS:

THE PAST

CRITICAL ISSUES AND DISADVANTAGES OF THE TRADITIONAL SYSTEM

- Results are not always flawless

- Operators must always be at the working station

- This process is not safe for operators who are constantly touching brushes

- Potential metal loss

- The whole process is manual

THE INNOVATION

THE ADVANTAGES OF AN AUTOMATED SOLUTION

- Flawless and customizable mirror finish polishing

- Operators carry out more qualified tasks

- Fast and safe processing

- No metal loss

- The whole process can be automated

WHICH INGOT TYPES DO YOU WANT TO POLISH?

T-Brush™ LGOLD > FROM 20 G TO GOOD DELIVERY INGOTS

T-Brush™ L

Power 7.5 kW

Power 7.5 kWTouch & PLC control panel board

HOW DOES

THE T-BRUSH™ METAL BRUSHING MACHINE WORK?

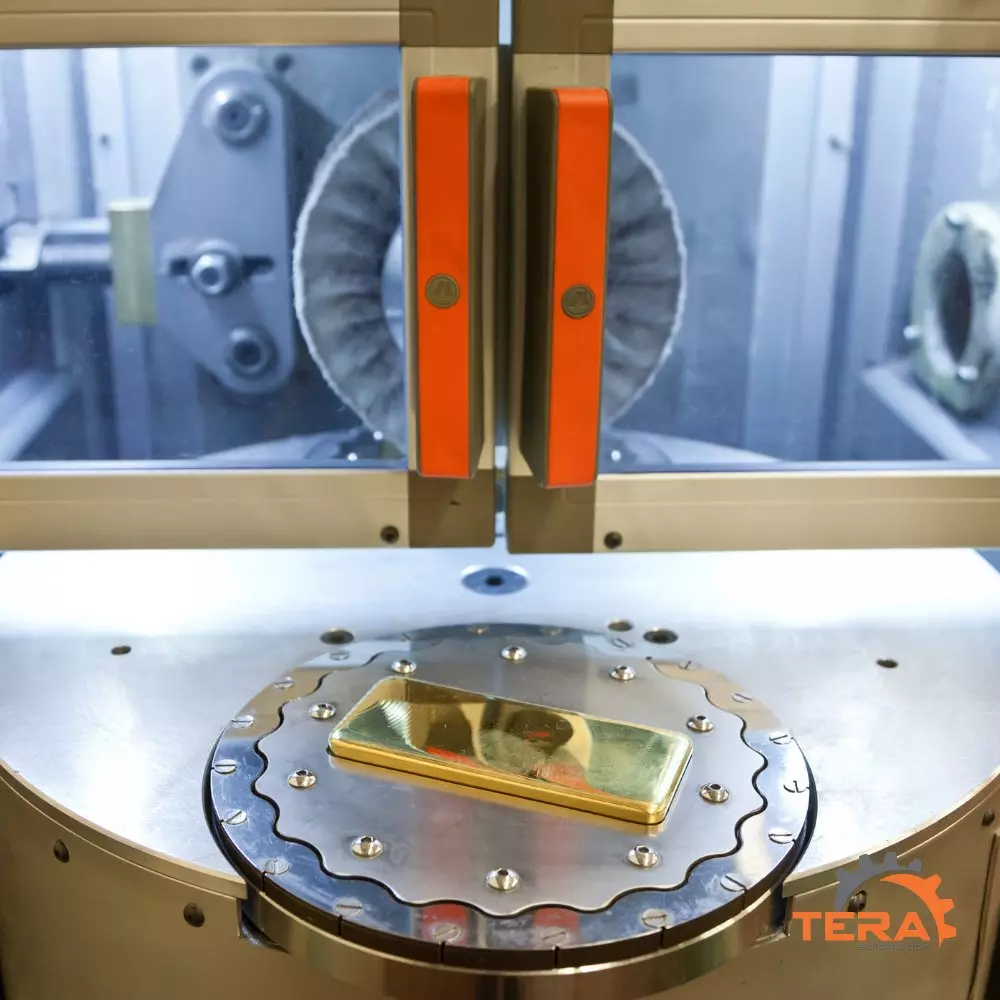

The T-Brush™ machine is equipped with two working stations installed on a rotating table, where templates are placed at a 180° angle: one working station operates inside the machine and the other one is located on the outside of the machine, where operators can access it. Ingots can be loaded manually or by a robot.

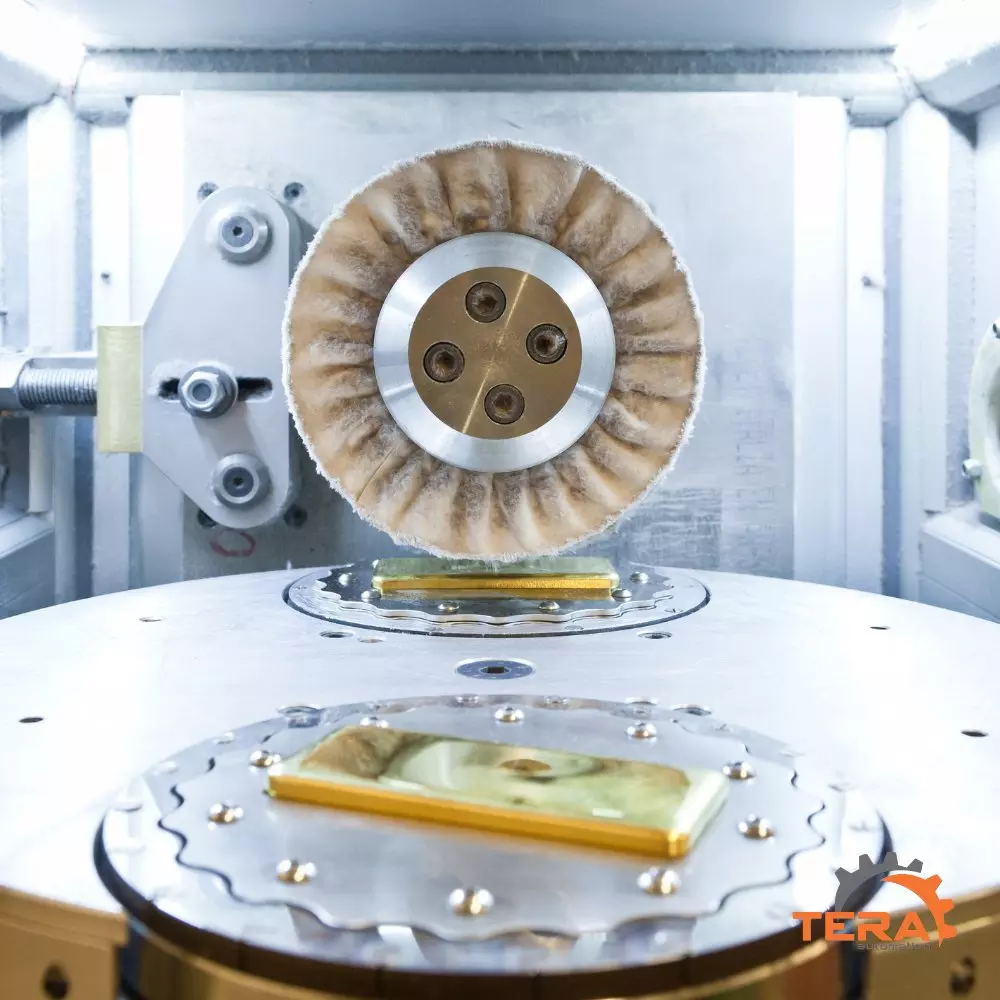

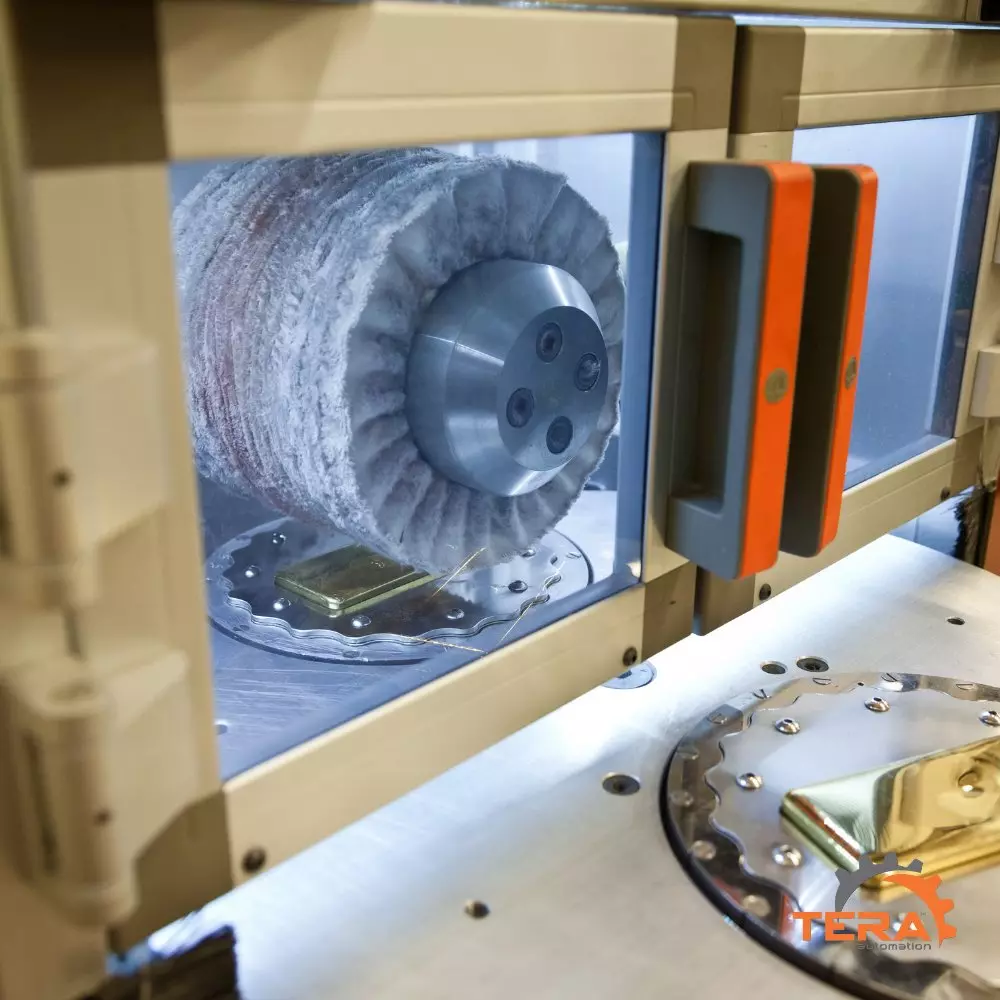

On the processing template there is a rotating brush, which can be made with different materials, ranging from soft to abrasive, according to the object and processing needs. The brush is enclosed inside the machine body for safety and practical reasons, and only activates when the door is shut.

During polishing, the brush stays put and the ingot, aligned under the brush and placed in the template, rises to its level to be brushed.

With a 180° table rotation, the brushed ingot is brought to the exterior of the cabinet, where either operators or a robot can collect it. In the mean time, that same movement brings the following ingot in the machine and places it under the brush, thus ensuring a continuous processing cycle.

CUSTOMER CARE

FULL, IMMEDIATE SUPPORT WITHOUT BORDERS

A support service can be deemed efficient, only if it does not require halting production for long periods of time, wherever the customers might be in the world.

Our support team can be reached via direct call, remotely or with maintenance contracts. That means saving time and money.

Constant availability of spare parts

Our support service is particularly efficient, because we provide spare parts which are manufactured even with our own CNC machine, our warehouse is fully stocked with the most important spare parts and we guarantee a fast delivery.

Along with the T-Brush™ machine, we provide an original Tera Automation spare parts package, so as to ensure that the machine always operates at full potential. Keeping a stock of the main spare parts is absolutely essential to guarantee production continuity and carry out simple maintenance tasks in an effective and timely manner. Our support team will create the spare parts package most suitable for your needs.

Consumables – Different kinds of brush sets

CONTACT US

ASK FOR MORE INFORMATION

TERA AUTOMATION S.R.L.

Via Romena, 7/9 - Loc. Porrena

52014 Poppi (AR) - Italy

Phone: +39 0575536625

Fax: +39 0575539851

E-mail: tera@tera-automation.com

TERA WORLDWIDE

USA: New York

INDIA: Mumbai

TURKEY: Istanbul

THAILAND: Bangkok

SPAIN: Barcelona