INFINIFEED

Feeding system with integrated App

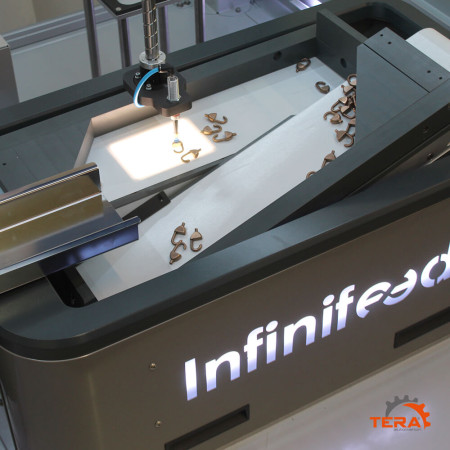

Infinifeed is the parallel counter-motion belt feeder that makes component conveying simple, fast, and efficient.

With its integrated App, you can configure the system, connect it with robots and vision systems, and manage and control all its functions.

ONE APP, ENDLESS FEATURES

- Gripping point control: take a picture of the component to be picked up and send it to the vision system.

- Startup and shutdown management

- Alerts and notifications control

- Belt speed adjustment

- Statistics and monitoring

INFINIFEED

BENEFITS

01

Intuitive interface

Clear commands and programming options make installation and use immediate.

02

Flexibility and adaptability

Easily integrate Infinifeed into your production line or use it as a stand-alone system.

03

Precision feeding

Guarantees accurate and consistent positioning of components and materials.

04

Smart design

Simplified disassembly thanks to a magnetically removable shell. Adjustable belt inclination based on the size and weight of the workpieces.

AN ESSENTIAL ELEMENT FOR INDUSTRIAL AUTOMATION

INTUITIVE SOFTWARE, INNOVATIVE HARDWARE: A USER FRIENDLY POWER SYSTEM

Aerospace

Water fittings

Automotive

Mechanics

Electric components

Electronics

Fashion accessories

Medical

- 1. Loading hopper

- 2. Vibrating channel for feeding blanks

- 3. Parallel belts with opposed motion

- 4. Optional illuminator

- 5. 2D vision system

- 6. Robot

- 7. Mobile control

TECHNOLOGY

01

From the mobile App, you can set the processing parameters, such as the gripping point of the workpiece and the feeding speed, and start the process with just a few steps.

02

The loading hopper releases the parts onto the vibrating channel, which conveys them toward Infinifeed, dropping them onto the belt.

03

The counter-motion of the belts guides the parts into the sensitive area of the 2D vision system, which processes the information and communicates with the robot, following the instructions previously set in the App.

04

The robot then picks up the part and positions it for the next processing stage, ensuring precision and continuity throughout the production cycle.