CUSTOM SOLUTIONS FOR THE PACKAGING OF GRAINS AND INGOTS

Tera Automation offers innovative machines for the packaging of grains and ingots, designed to meet all format requirements.

We provide a wide range of solutions, from bag sealing machines, ideal for the secure packaging of grains, to blister technology, perfect for small-format coins and ingots. For medium-format ingots, our machines use shrink wrap, ensuring maximum efficiency and protection. Rely on Tera Automation for packaging solutions that combine precision and reliability.

PACKAGING SOLUTIONS

T-BLISTER

Blister machine for ingots and minting

T-Blister™ is a high frequency electric welding machine - for blister packaging of casted or minted bars & coins - with designed system for welding PVC sheets.

Is provided with rotating table and two working stations (loading/welding) to be operated manually. Easy to use and with excellent reliability, it allows easy handling and repeatability of the package quality. The machine is operated through a microprocessor thereby guaranteeing a high and constant productive speed, assuring an easy and fast man/machine interface.

Final blister can have a single or double welding according to the customer’s requirements (only along the perimeter of the package or also around the product). This provides a great guarantee as it prevents product escapes in case of blister breakage.

T-PACK

Ingot packing and thermoforming machine

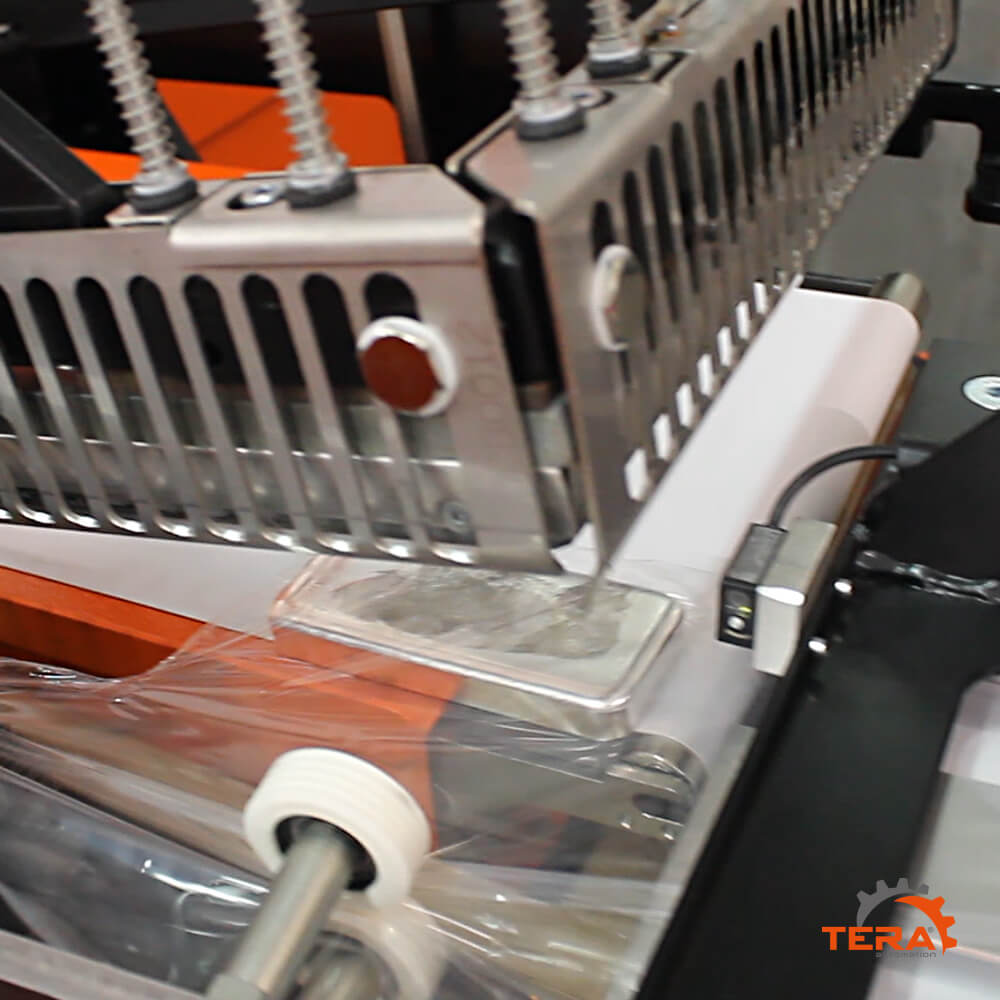

T-Pack™ is an automatic compact and modular packaging and shrink-wrapping machine for precious metals ingots.

This packaging machine seals precious metals ingots - as well as objects of different materials - with a heat shrink film.

It can be easily integrated to any production line and offers customizable wrapping solutions.

T-FILL & SEAL

Dosing and packing machine for grains

T-Fill&Seal™ is an automated machine that combines the dosing and packaging of metallic granules, optimizing precision and speed. Equipped with an integrated precision load cell and a vertical packaging system, it simplifies a complex process while reducing human error. Thanks to an integrated emptying system, it prevents metal losses and contamination, ensuring effective cost reduction.

THE 3 CHARACTERISTICS OF PERFECT PACKAGING

Product Visibility

The precious metals market demands exceptional aesthetic quality and zero product imperfections. Visibility is synonymous with reliability, which is why every type of packaging must not conceal the product but highlight it.

Packaging Durability

Packaging for the world’s most precious content must ensure maximum resistance to impacts and, above all, against theft or tampering.

Information

Grains, coins, or ingots must include a series of traceability details. Our packaging machines are all integrable with label printers that display all the necessary data to ensure the product's full compliance.