T-DOSING

High-precision automatic dosing machine

T-Dosing™ is an industrial machine for the precious metals sector that automates the weighing of the granules used for the production of ingots, one of the most delicate stages of the process. The accuracy of the weight is a determining factor for investment ingots, as underweight ingots cannot be marketed, and overweight ingots would result in a clear economic loss for the producer.

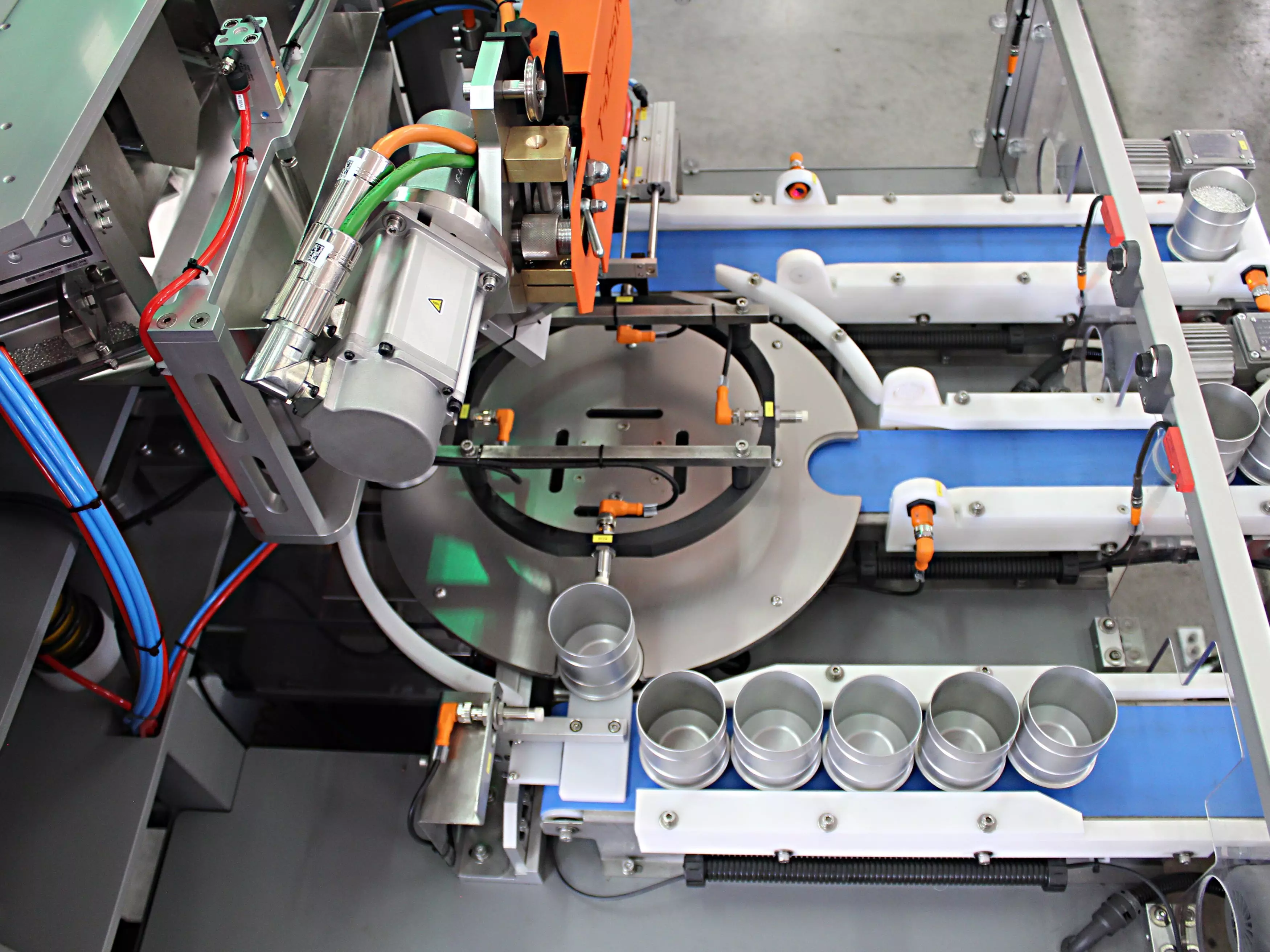

T-DOSING CONSISTS OF:

- 2 or 4 loading hoppers

- 1 collection hopper for macro-weighing

- 2 vibrating channels

- Rotating circular platform

- 3 conveyor belts (inlet, outlet, and waste)

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Convenience

Simply set the working recipe to ensure continuous production without wasting time, with accuracy to the centigram or milligram, otherwise unattainable by humans.

02

Reliability

Jars with non-compliant weights are automatically discarded into their respective recovery areas, preventing the melting of ingots with incorrect weights.

03

Precision

The extraordinary accuracy of the load cells prevents any weight adjustments before and after melting.

04

Efficiency

The extremely low number of remelts helps optimize costs and resources.

MODELS

T-Dosing 2H features 2 hoppers, one for coarse granules and the other for fine granules.

T-Dosing 4H features 4 hoppers, 2 for gold granules (coarse and fine), and 2 for silver granules (coarse and fine), allowing for the processing of 2 different metals.

| Dimensions | 1200 x 1400 x h1900 mm |

| Production dosing | da 1 oz a 1 kg |

| Production capacity for 100 g | 160 ÷ 180 pz/h |

| Production capacity for 1 kg | 100 ÷ 120 pz/h |

| Weighing unit capacity | up to 1200 g (excluding jar) |

| Accuracy load cell mg | + 0,005 g / - 0 g |

--

T-Dosing Plus is equipped with a double cutting head to double productivity.

Available in the 2 hopper (2H) or 4 hopper (4H) versions.

| Dimensions | 1580 x 1700 x h2020 mm |

| Production capacity for 100 g | 300 ÷ 340 pcs/h |

| Production capacity for 1 kg | 180 ÷ 220 pcs/h |

| Weighing unit capacity | up to 1200 g (excluding jar) |

| Accuracy load cell mg | + 0,005 g / - 0 g |

| Hopper 45 l | Hopper 25 l | |

|---|---|---|

| Grain diameter | 2,5 mm ≤ Ø ≤ 5 mm | 0,5 mm ≤ Ø ≤ 2,5 mm |

| Hopper volume | ≈ 500 kg Au / 270 kg Ag | ≈ 290 kg Au / 155 kg Ag |

T-Dosing HP (High Production) is a semi-automatic cycle machine designed for dosing and packaging grains into bags.

It is equipped with 2 hoppers and requires an operator to place the packaging bags during the filling phase.

| Dimensions | 1050 x 1080 x h2100 mm |

| Production capacity | up to 60 pcs/h for 25 kg bags |

| Weighing unit capacity | 50 kg |

| Accuracy | +10 g / - 0 g |

| Suggested grain diameter | 1 mm ≤ Ø ≤ 5 mm |

--

T-Powder Dosing is a system for dosing and packaging metallic powders or salts into bottles.

| Dimensions | 4400 x 3010 x h2490 mm |

| Range of formats | 50 g > 1400 g |

| Production capacity | 100 pcs/h of 100 g bottles |

| Accuracy | ± 0,1 g |

| Hopper loading volume | 20 l |

| Maximum weight for load cell | 4200 g |

| Accuracy load cell | 0,01 g |

--

TECHNOLOGY

HOW DOES T-DOSING MACHINE WORK?

01

The grains, properly sieved by diameter through T-Screening™, are loaded into the respective hoppers.

02

From there, grains flow into vibrating channels that lead them toward the first hopper, where macro-weighing is performed. The flow speed of the grains decreases as the target weight is approached.

03

Once 98-99% of the target weight is reached, the grains are transferred to a special empty container placed on the analytical load cell, which detects the exact missing weight, compensated by a wire cut.

04

All containers that exceed the tolerance window set by the operator are excluded from the processing line.

TAILORED AUTOMATION

AUTOMATION FOR THE HIGHEST ACCURACY

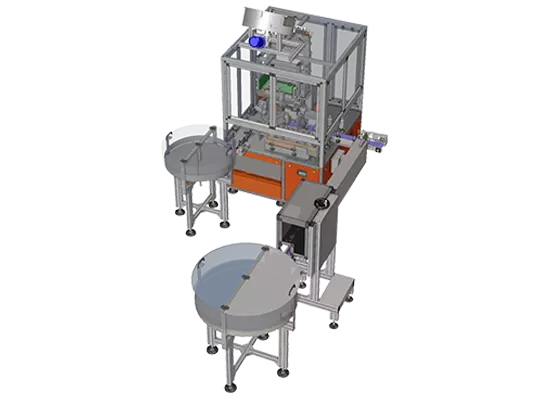

Each Tera Automation machine can be conceived as part of a modular line which can be combined according to the company's needs and facility space. Each machine can be fitted to existing machines and a full line can be developed over time.

T-Dosing™ was designed to perform an extremely accurate dosing - with a thousandth of a gram accuracy - of precious metals used for casting and may be combined with other machines, according to each operator's particular needs.