T-FLEXICELL ROBOTIC CELL FOR CNC MACHINE TENDING

T-FLEXICELL™

ROBOTIC CELL FOR CNC MACHINE TENDING

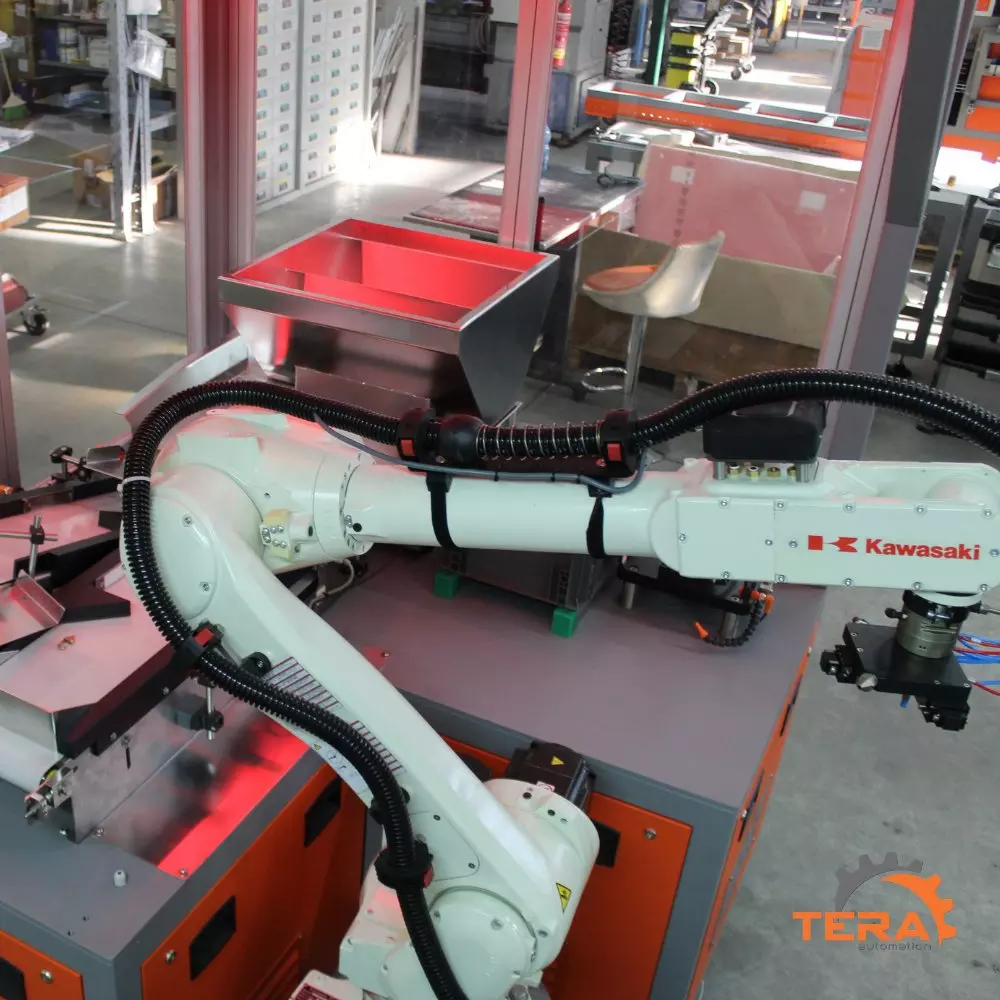

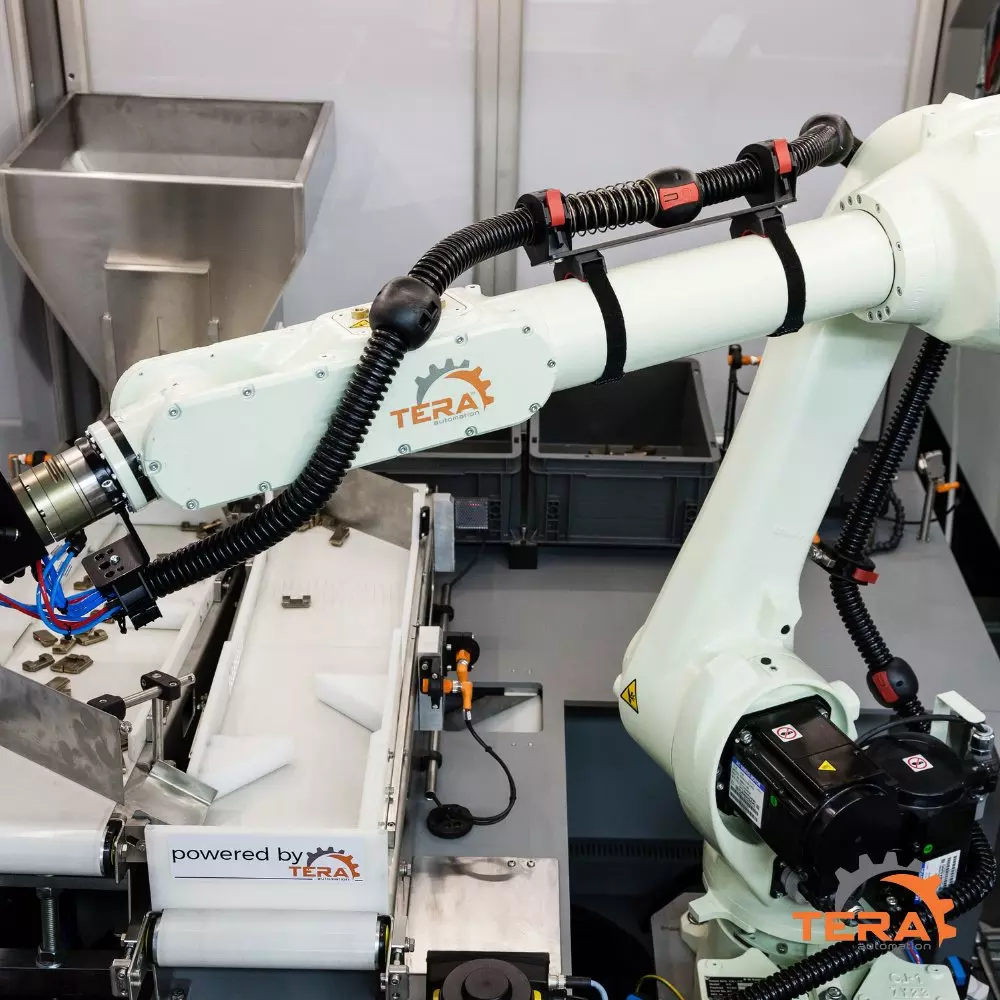

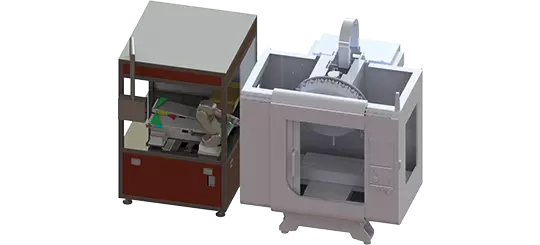

T-Flexicell™ is a robot cell whose purpose is to manage the loading/unloading of components of different sizes. The robotic cell can handle several vises both as part of a single process (the same operation is repeated on several vises), or in a multiprocessing (different operations across several vises).

The most distinctive feature of the range of robotic cells for Computer Numerical Control machine tending called T-Flexicell™ is definitely its flexible application: as a matter of fact, the cell is able to process components with different shapes and sizes thanks to an infeed system which allows loading items randomly.

The purpose of our cells is to maximize CNC machine efficiency and optimize production flow, thus obtaining better performances.

T-Flexicell™ also takes its name from its flexible shape: its compact size is without any doubt a big advantage and, depending on the application type, it can change design according to the specific needs of the sector and the client.

INFINIFEED

Infinifeed is the innovative opposed-motion parallel belt feeder for conveying components.

Its integrated App enables configuration and integration operations with the robot and vision system, as well as device control and management.

AREAS OF APPLICATION OF ROBOTIC CELLS FOR CNC MACHINE TENDING

- Fashion accessories (e.g. secondary machining of components)

- Automotive

- Aeronautics

- Aerospace

- Mechanical

- Taps and fittings

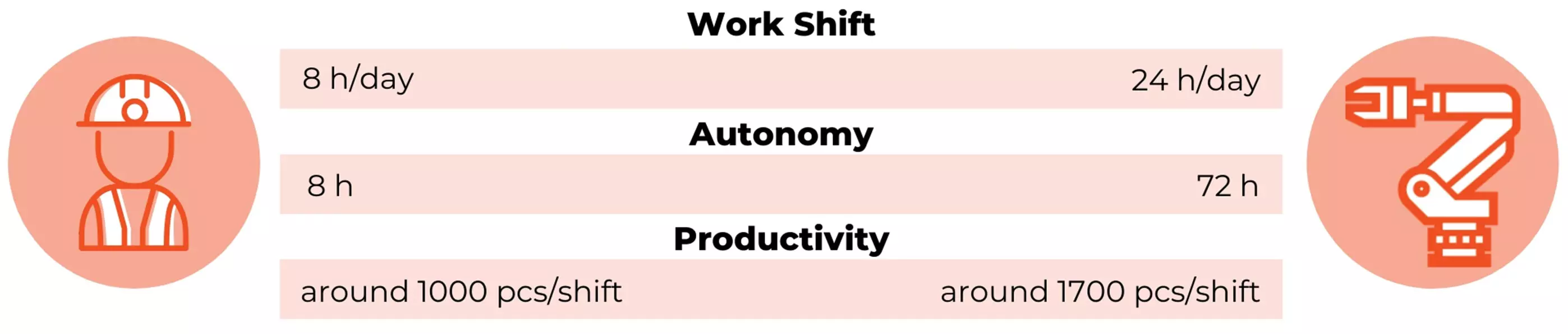

THE ADVANTAGES OF A ROBOTIC CELL FOR CNC MACHINE TENDING

- 96-hour autonomy

- Output increase

- Return on investment in less than one year

- Consistent quality across the work shift

- 24/7 non-stop availability

- Health and safety for operators and the environment

- High flexibility and precision

ROBOTIC CELL

T-FLEXICELL™FOR CNC MACHINE TENDING

T-FLEXICELL™

THE T-FLEXICELLTM ROBOTIC CELL FOR CNC MACHINE TENDING IS MADE OF:

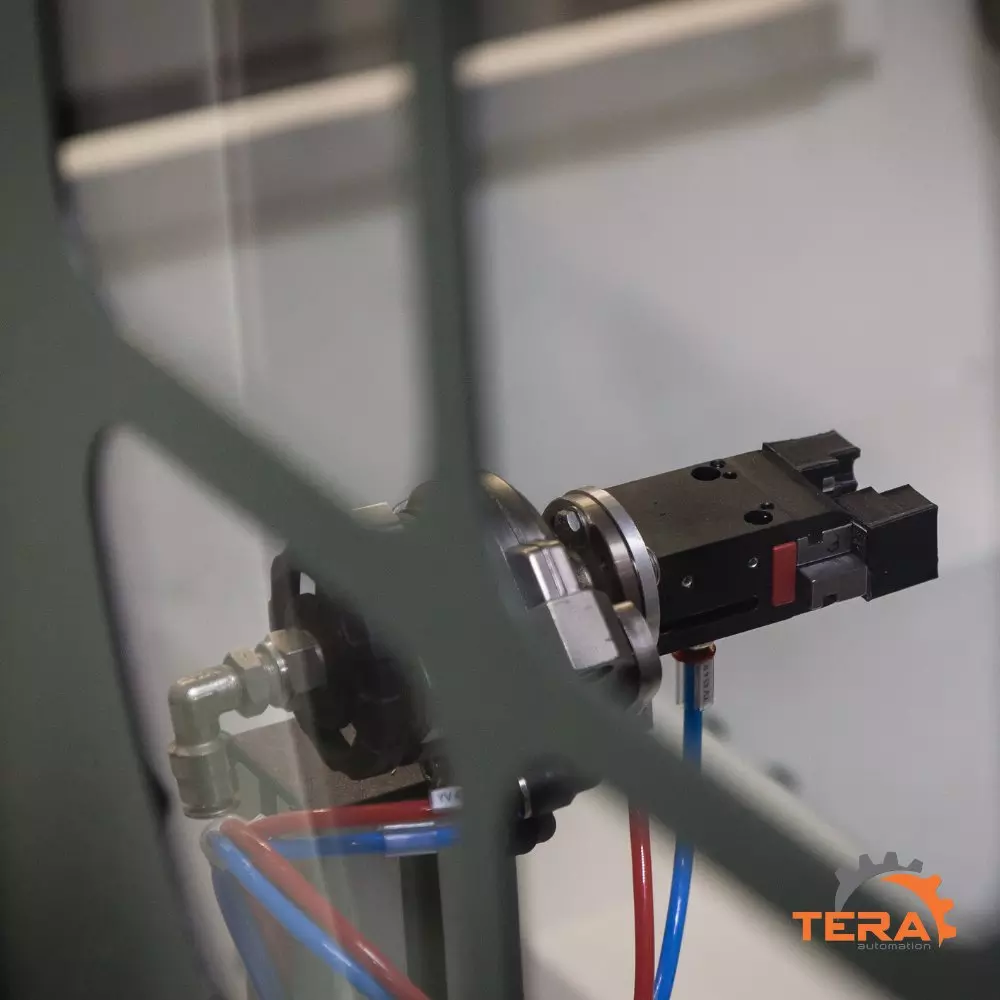

- A supporting structure with doors equipped with safety interlocks: each door is fitted with a safety sensor to block the cell in case of unintentional opening or emergency;

- Vibrating hopper to load rough components;

- T‐Loop Feeder TM‐ Closed-loop belts with opposing directions to flip and align rough components;

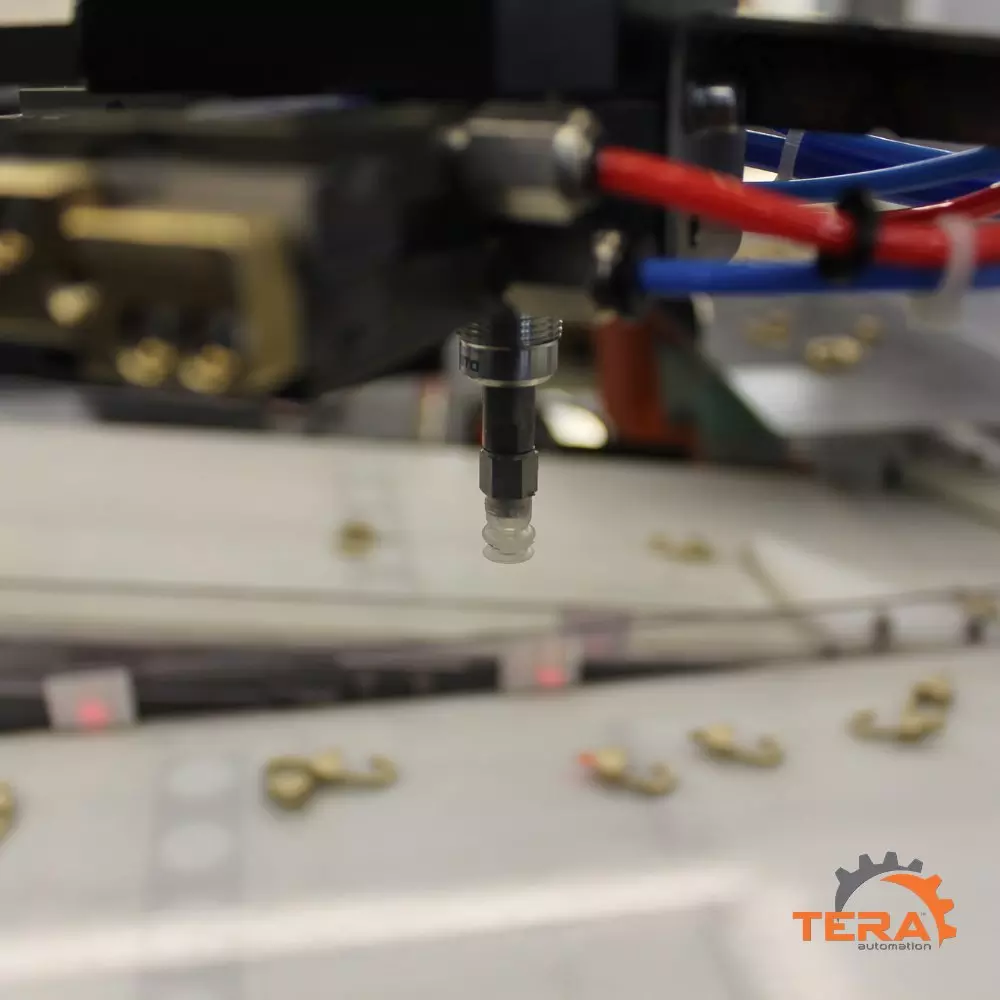

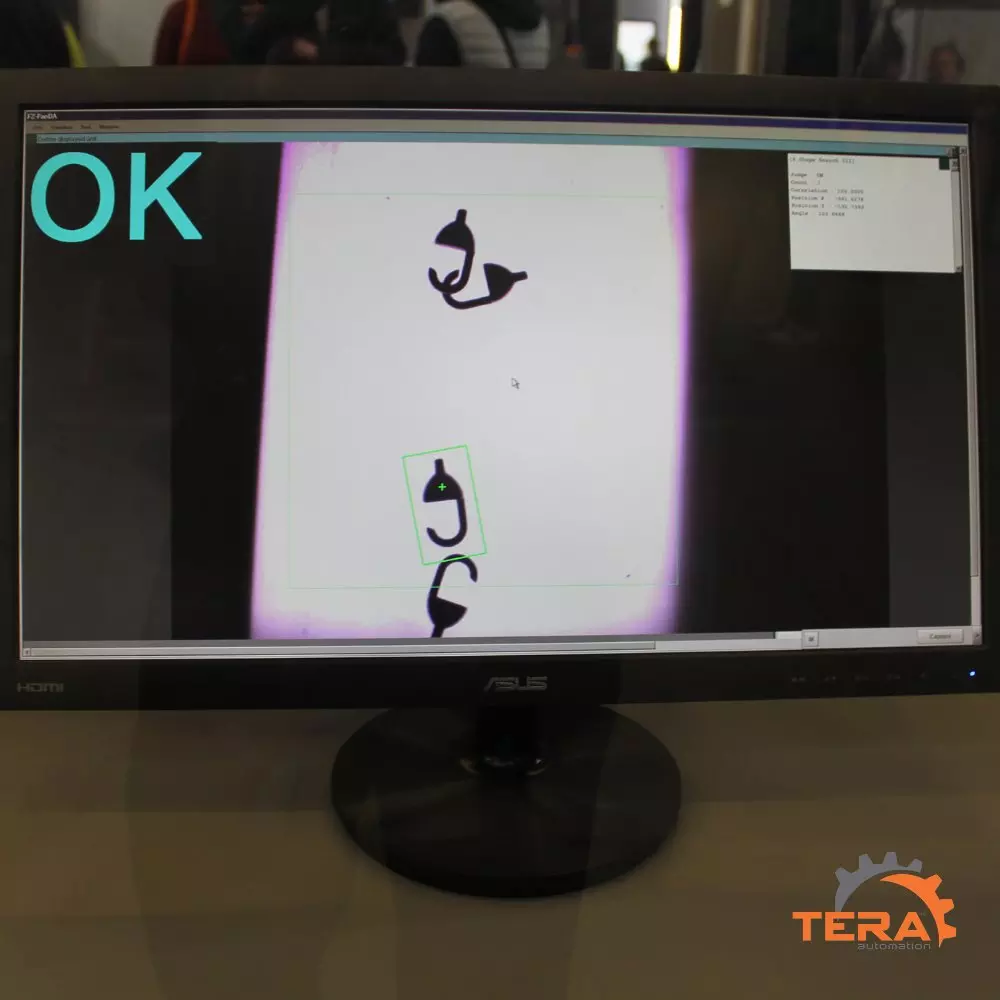

- 2D vision system with infrared backlight to detect and recognize rough components on reflecting surfaces;

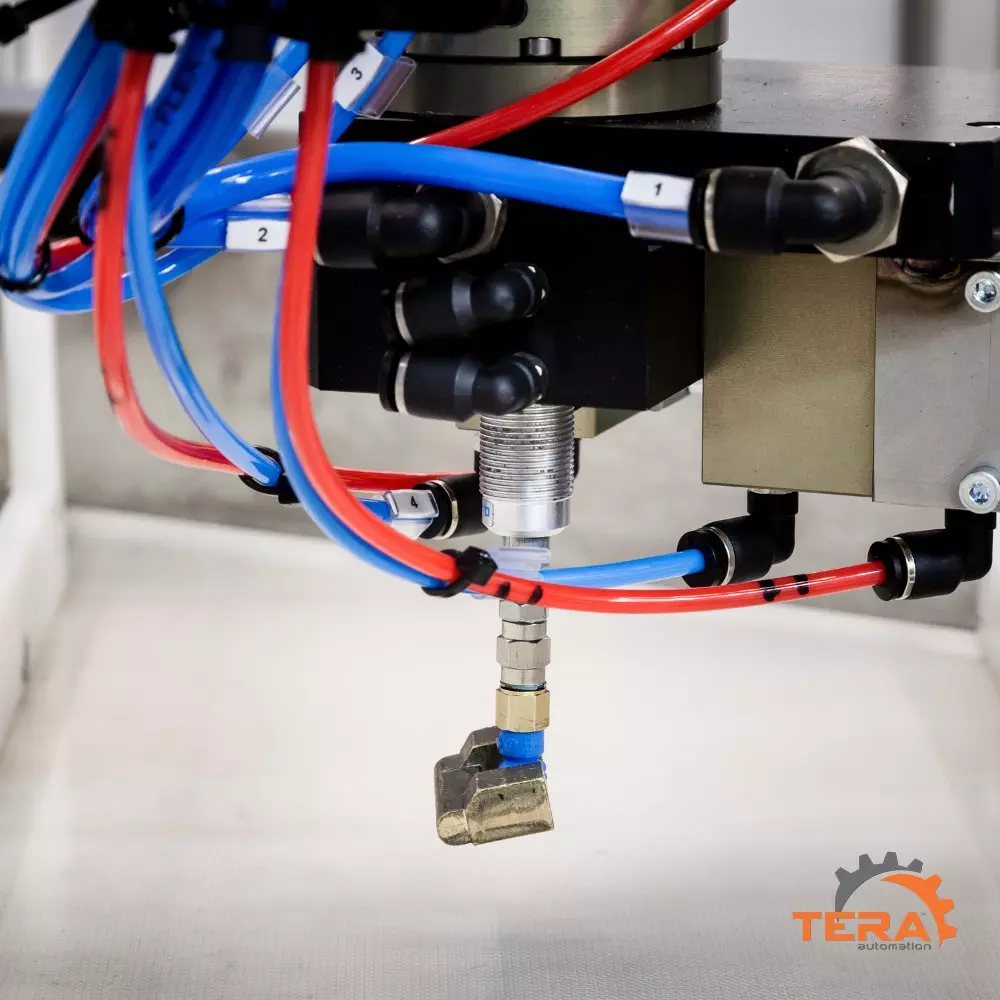

- Multi-place zero-adjustment template for rough components , with a sensor to detect the presence of components and a blowing system for those components which do not comply to the gripping system;

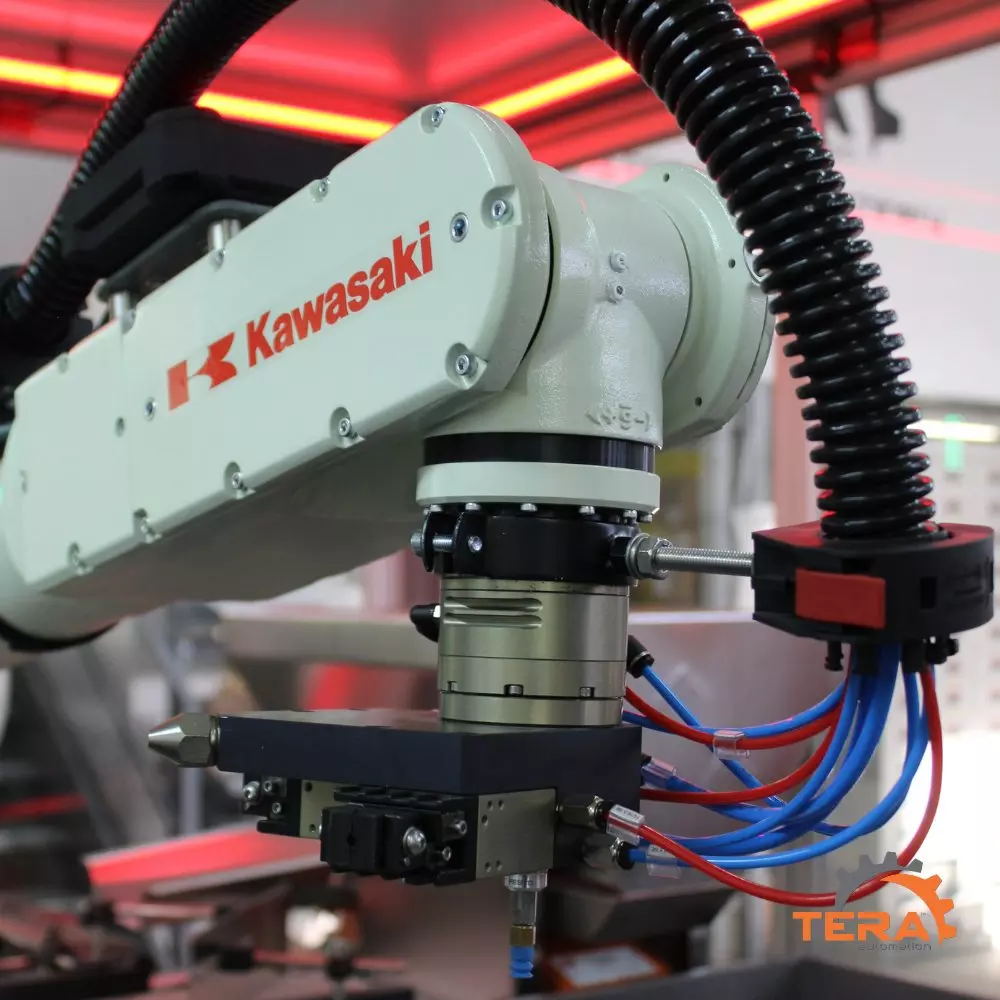

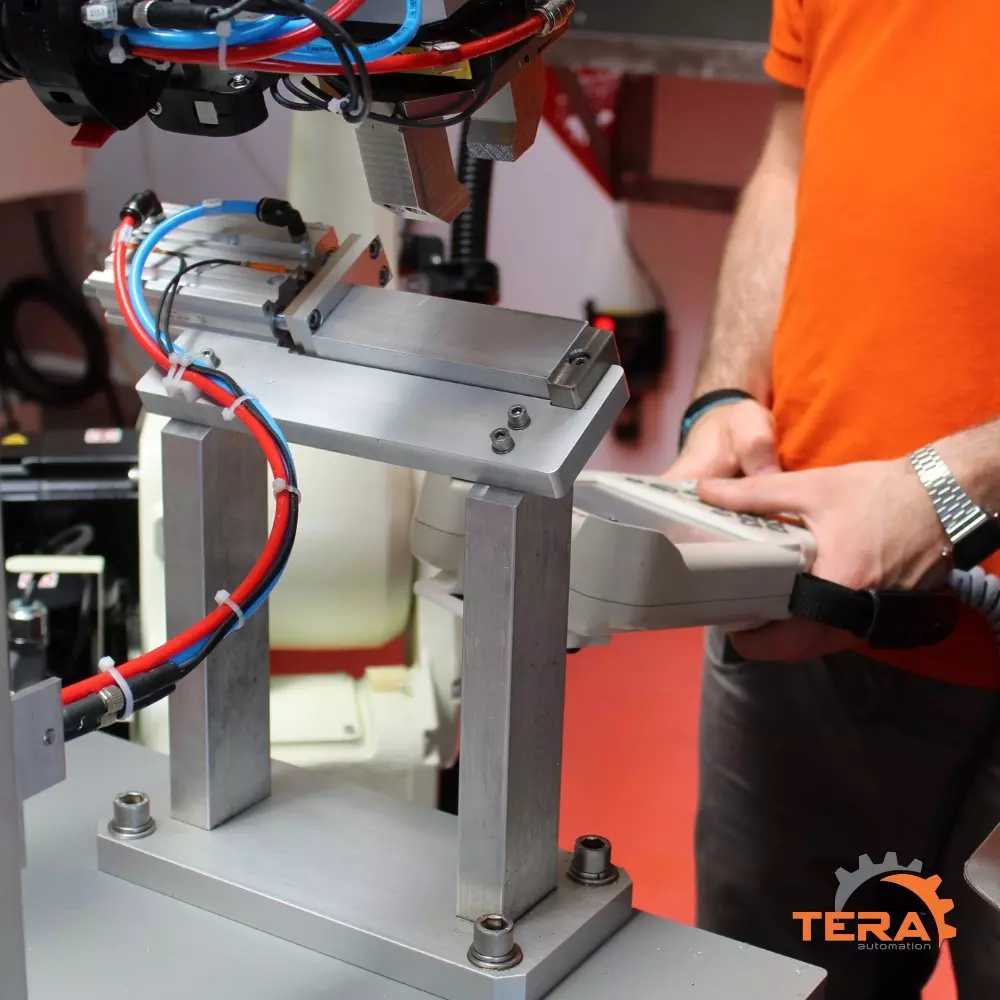

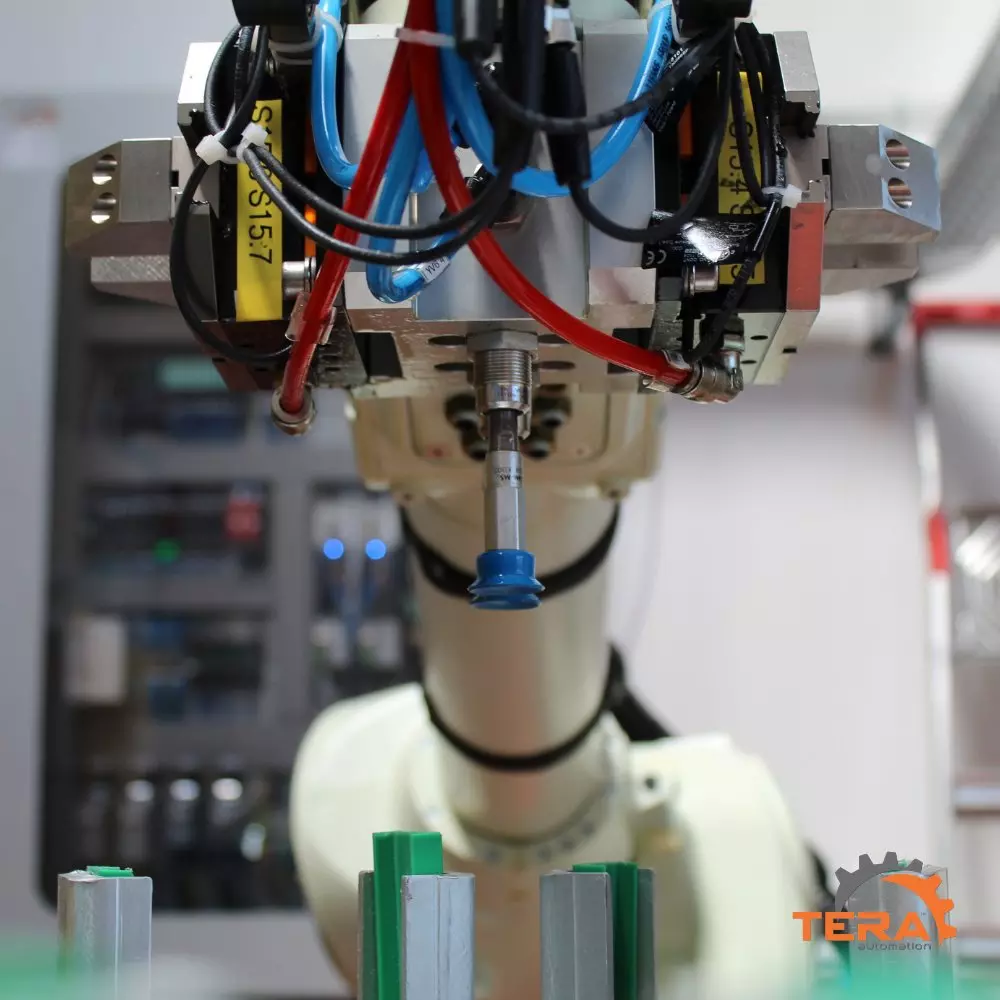

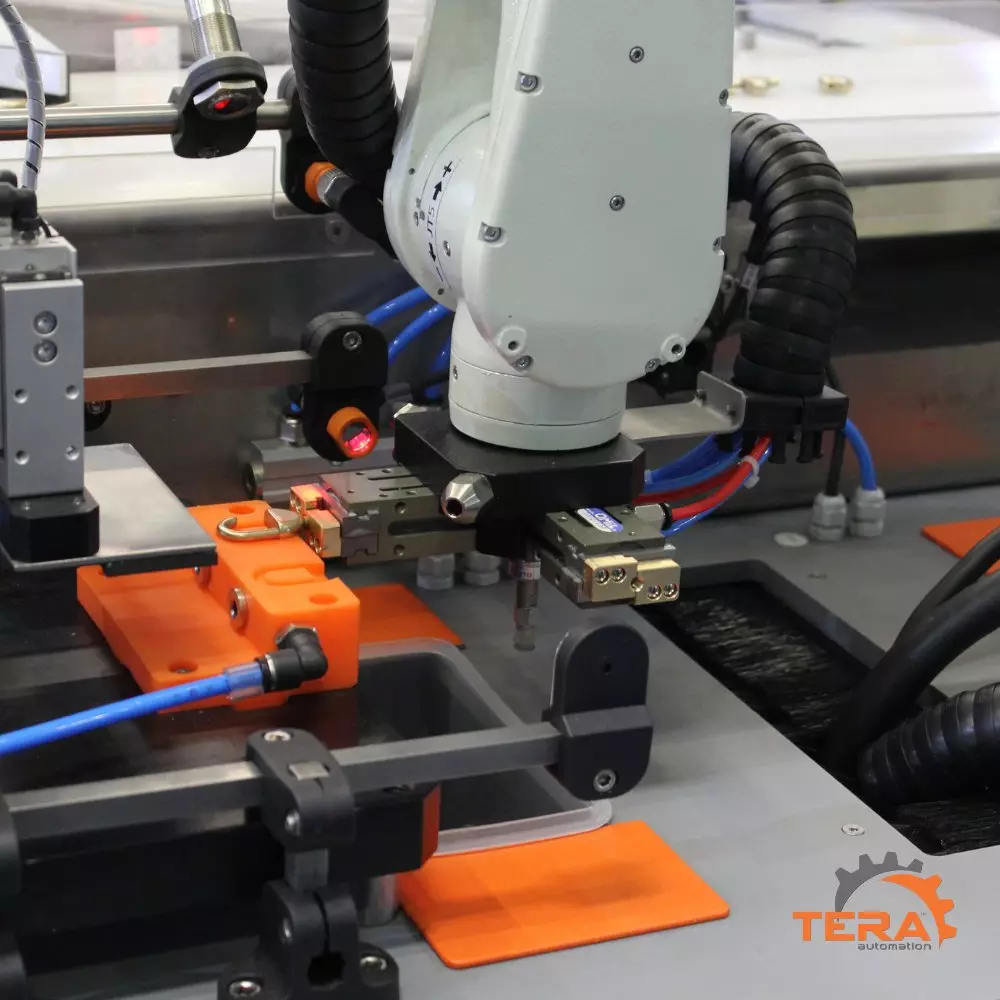

- Anthropomorphic robot with optional Industry 4.0, equipped with:

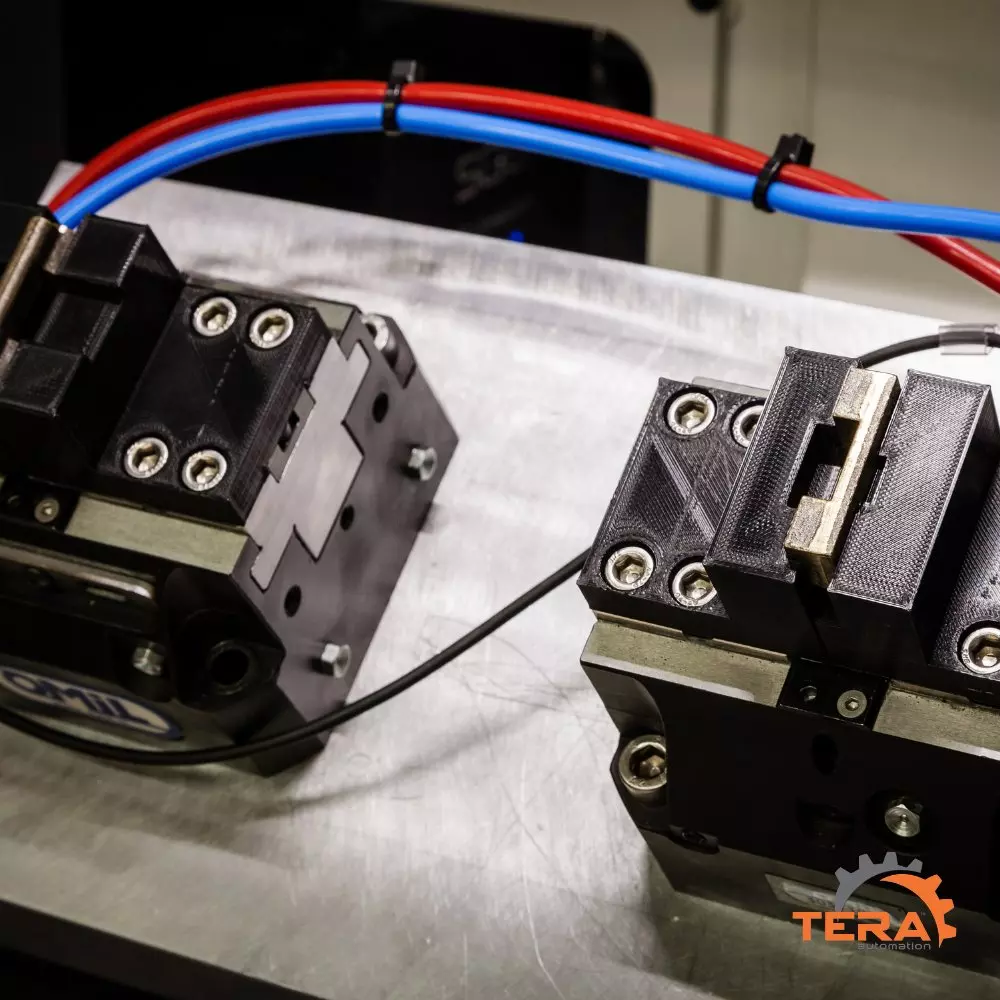

- Gripping system with suction cups to pick components up from the T-Loop Feeder TM;

- Dual gripper, equipped with a blowing system, to pick up rough/processed parts;

- Two recovery areas for components:

- one recovery area for components which were discarded by the zero-adjustment template;

- one recovery area for finished and compliant components.

- HMI with touch screen to manage and control the T‐Flexicell TM;

- Electric panel board with electric equipment and CNC and robot connections

HOW DOES

THE T-FLEXICELL™ FOR CNC MACHINE TENDING WORK?

1 – Operators load the rough components into the hopper;

2 – The robot picks the rough component(s) from the T-Loop Feeder TM;

3 – The robot places the rough component(s) on the multi-place calibration template;

4 – The robot collects the rough component(s) from the zero-adjustment template and loads it/them in the CNC vise;

5 – The CNC processes the rough component(s);

6 – The robot unloads the components from the computer numerical control machine and releases them in the designated collection area.

OPTIONAL ACCESSORIES

Laser Guards

The protective box with steel and Plexiglas framework can be equipped with a laser guard system: as soon as operators come closer, the laser guard systems tells the robot to slow down and when operators access the robot's working space, the robot stops. This system allows getting rid of physical barriers, while keeping a high level of security in compliance with UNI EN ISO 13855:2010 standard.

Industry 4.0 package: JARVIS system + T-Router™

The robotic cell can be equipped with a collection, storage and management system of production data (JARVIS) to manage the machine in a smarter way. This software is supported by a T-Router which can also solve potential problems and control the cell remotely. Learn more about Tera's tools for a smart factory.

Security Camera Set

Four security cameras mounted on the cell and on the CNC allow you to constantly monitor the whole process from your smartphone whenever you want.

CUSTOMER CARE

FULL SUPPORT

For each T-FLEXICELL TM installation, we provide our clients with training, so that operators can learn how to easily handle cells.

Moreover, our 24/7 assistance service prevents long production interruptions, wherever our clients might be in the world.

Our support team can be reached via direct call, remotely or with maintenance contracts.

CONTACT US

ASK FOR MORE INFORMATION

TERA AUTOMATION S.R.L.

Via Romena, 7/9 - Loc. Porrena

52014 Poppi (AR) - Italy

Phone: +39 0575536625

Fax: +39 0575539851

E-mail: tera@tera-automation.com

TERA WORLDWIDE

USA: New York

INDIA: Mumbai

TURKEY: Istanbul

THAILAND: Bangkok

SPAIN: Barcelona