AUTOMATION SYSTEMS FOR THE PRECIOUS METALS INDUSTRY

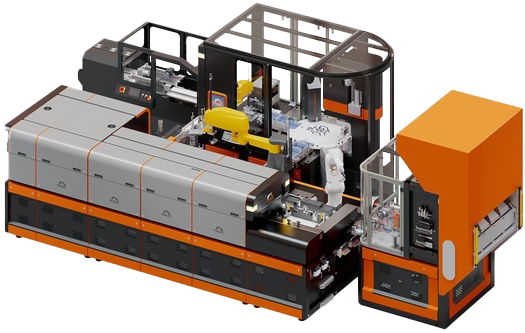

We have developed highly efficient automated systems that are specifically designed for the investment precious metals sector. All our machines can achieve increasing levels of industrial automation, either integrating with existing equipment or completely redesigning the setup. Our industrial automation solutions can be integrated with various types of robots to maximize productivity and improve the quality of the finished product.

The range of Tera Automation's machinery covers the entire production process for bars and coins, transforming metal from its powdered form to the most brilliant and attractive version of the final product.

OUR PRODUCTS CATALOG

PACKAGING

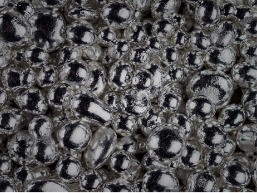

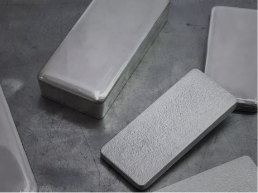

Solutions for packaging both granules and ingots, ensuring product protection and presentation.

T-LINE™

FULLY AUTOMATED PRODUCTION LINE FOR THE CONTINUOUS PRODUCTION OF INGOTS

All our automations can be connected to one another or to other existing machines.

Discover Tera Automation's most automated system for the production of gold and silver ingots.