T-FINISHING

Integrated serialisation and ingot stamping system

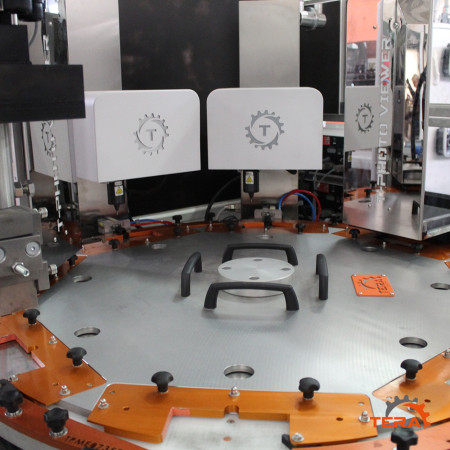

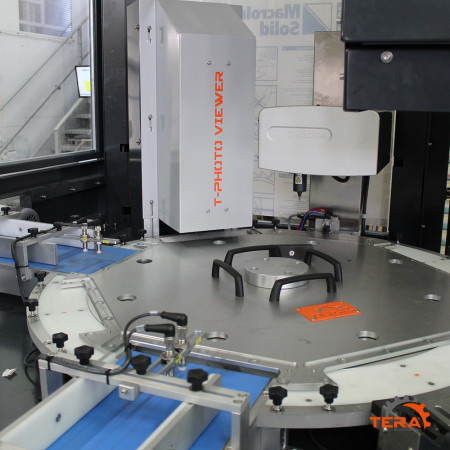

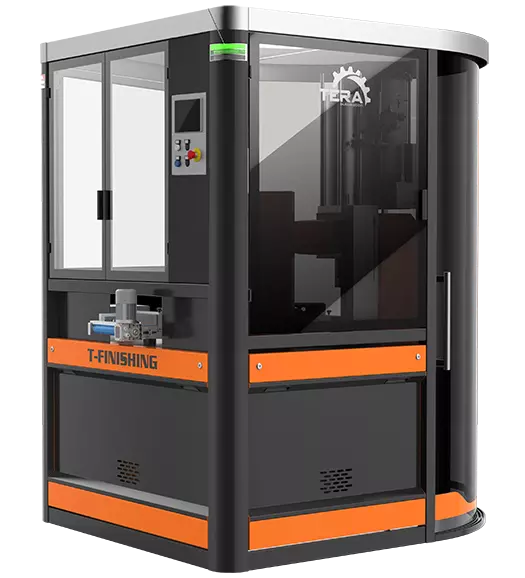

To say that T-Finishing™ is just a machine would be an understatement, since it combines several tools necessary for the final processing steps of precious metal ingots in one working station. The standard machine configuration includes a hydraulic press for the logo stamping and a micro-dot marking machine for the serialization of numerical data. However, thanks to its circular shape, the machine can be equipped with many integration tools, such as the laser marking machine or an optical visor (T-Photo Viewer) for quality control.

With the T-Finishing™ process, it is possible to stamp the serial number and mark the company's logo on gold and silver ingots of various size.

This system can significantly increase production levels, optimize time dedicated to each process and reach full autonomy, can be equiped with a robot which can pick and place ingots on the automated cell.

T-FINISHING CONSISTS OF:

- Inlet conveyor belt

- Interchangeable rotary table

- T-Press: 33t hydraulic press for stamping the company logo

- T-Numbering: microdot marking machine for numerical serialisation

- Outlet conveyor belt

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Efficiency

Press and marking machine in one module. Less time must be dedicated to logo application and serialization which are now carried out in a single machine

02

Speed

Automatic finishing of large volumes in reduced times.

03

Safety

Increasing safety for staff.

04

Flexibility

The whole process can be automated, if it is fitted with a robot and other working stations thanks to its circular shape. The whole production can be traced with integrated software devices (JARVIS).

MODELS

| Dimensions | 2200x1900xh2330 mm |

| Ingot type | from 50 g to 100 oz Au/Ag |

| Hourly production | from 120 to 500 pcs/h |

--

This model is designed to be integrated into an automated line.

It consist of:

- Separated Scara Robot

- Discard conveyor belt

- Interchangeable rotating table

- Analytical weight measurement cell (scale)

- T-Press: 33 t hydraulic press for company logo stamping

- T-Numbering: microdot marking machine for numerical serialization

- T-Photo Viewer: vision system with OCR

- Outlet conveyor belt

| Dimensions | 2200x1900xh2330 mm |

| Ingot type | from 50 g to 100 oz Au/Ag |

| Hourly production | from 120 to 500 pcs/h |

--

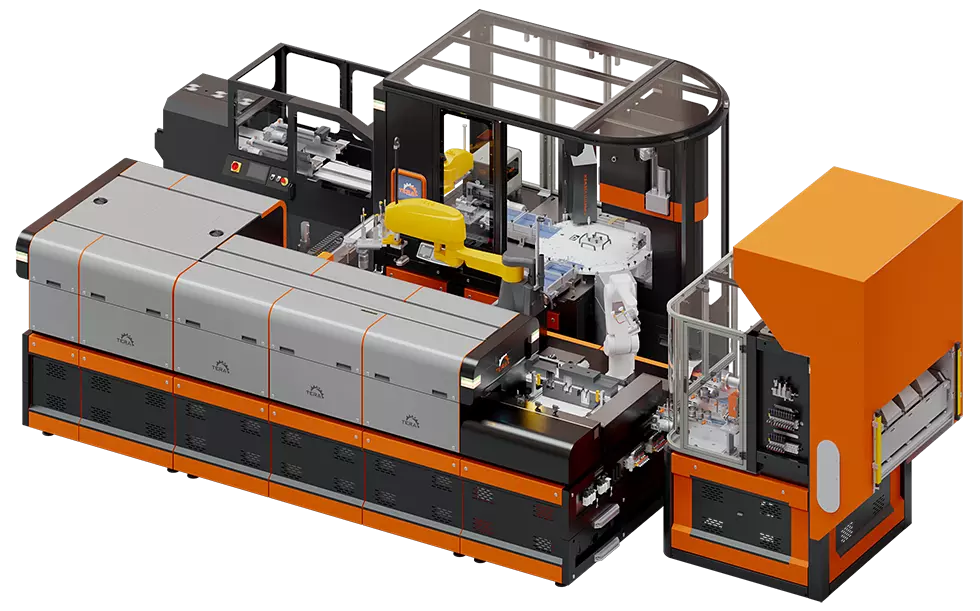

This model is designed to be integrated into an automated line and to handle large quantities of small/medium-sized ingots arranged on pallet.

It consist of:

- Integrated Scara Robot

- T-Vision: for quality control of ingots exiting the tunnel furnace

- Interchangeable rotating table

- Analytical weight measurement cell (scale)

- T-Press: 33 t hydraulic press for company logo stamping

- T-Numbering: microdot marking machine for numerical serialization

- Outlet conveyor belt

| Dimensions | 2200x1900xh2330 mm |

| Ingot type | from 50 g to 100 oz Au/Ag |

| Hourly production | from 120 to 500 pcs/h |

--

TECHNOLOGY

HOW DOES T-FINISHING WORK?

01

INGOT PLACING: The standalone version of T-Finishing does not include an analytical weight measurement cell (scale). Therefore, it is assumed that the operator checks the weight of the ingot before putting it in the inlet conveyor belt of the T-Finishing.

02

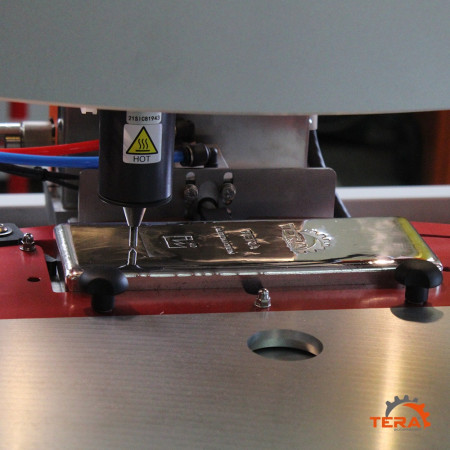

INGOT STAMPING: The first station to which the ingots arrive is the T-Press. The rotating table brings the ingot under the stamping die, positioning it in the dedicated working area. The press detects the presence of the ingot and carries out the stamping. Upon its completion, the table activates again, bringing a new ingot under the stamping die and moving the one already stamped to the following station.

03

INGOT MARKING: The second station is the T-Numbering machine, where the ingot is serialized according to the customer’s requests.

04

INGOT OUTPUT: At the end of all operations, the rotating table brings the ingot to the outlet conveyor belt, where it will be picked up by the operator.

TAILORED AUTOMATION

AUTOMATION FOR AN UNPARALLED CUSTOMIZATION OF INGOTS

Each Tera Automation machine can be conceived as part of a modular line which can be combined according to the company's needs and facility space. Each machine can be fitted to existing machines and a full line can be developed over time.

T-Finishing™ is a comprehensive finishing system for precious metal ingots, which, despite its already high automation level, can be combined to other machines, according to each operator's specific needs.