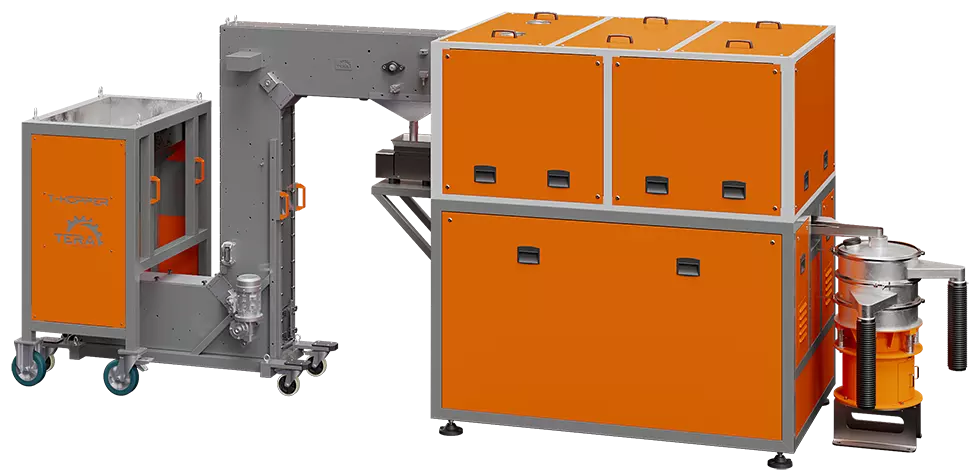

T-DRYRAY

Automated drying system

Metal grains must be perfectly dried to produce ingots. A one-kilogram gold ingot must be made with one kilogram of actual grains, without any moisture residues. That is why Tera Automation has developed the automated system called T-Dryray™, in which grains undergo a full drying process.

Grains are processed continuously, thus significantly optimizing the time required for this very important step.

Two units can be put in parallel to process gold and silver separately.

T-DRYRAY IS COMPOSED BY:

- Vibrating inlet channel

- Refractory muffle

- Electric resistance refractory heater

- Rotating coclea

- Grains recovery tray

- Outlet vibrating channel

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Automation

Continuous, time-saving processing in a single process.

02

Quality

Perfect drying of grains with no moisture residues.

03

Efficiency

Fully automated drying process, which does not require the constant presence of operators. No metal loss and costs optimization due to a single processing step.

04

Versatility

Possibility of integrating two units in parallel to process gold and silver separately.

MODELS

| Dimensions | 1700 x 2300 x h2800 mm |

| Power | 35 kW |

| Hourly production of Ag grains | from 300 to 350 kg |

| Hourly production of Au grains | from 300 to 400 kg |

--

| Dimensions | 3000 x 2300 x h2800 mm |

| Power | 35 kW |

| Hourly production of Ag grains | from 300 to 350 kg |

| Hourly production of Au grains | from 300 to 400 kg |

--

TECHNOLOGY

HOW DOES T-DRYRAY™ MACHINE WORK?

01

Wet grain is loaded into a hopper feeding the vibrating inlet channel.

02

The inlet channel vibrating moves metal grains inside a muffle heated by means of electrical resistances. The refractory muffle contains a rotating stainless steel cochlea.

03

This combination of elements along with the controlled rotation of the cochlea allows the perfect drying of the grain, favouring the evaporation of any moisture residue and preventing the risk of oxidation.

TAILORED AUTOMATION

AUTOMATION FOR PERFECTLY DRIED GRAINS

Each Tera Automation machine can be conceived as part of a modular line which can be combined according to the company's needs and facility space. Each machine can be fitted to existing machines and a full line can be developed over time.

T-Dryray™ was designed with the purpose of perfectly drying grains and can be combined with other machines, according to each operator's specific needs.