T-GRAINS

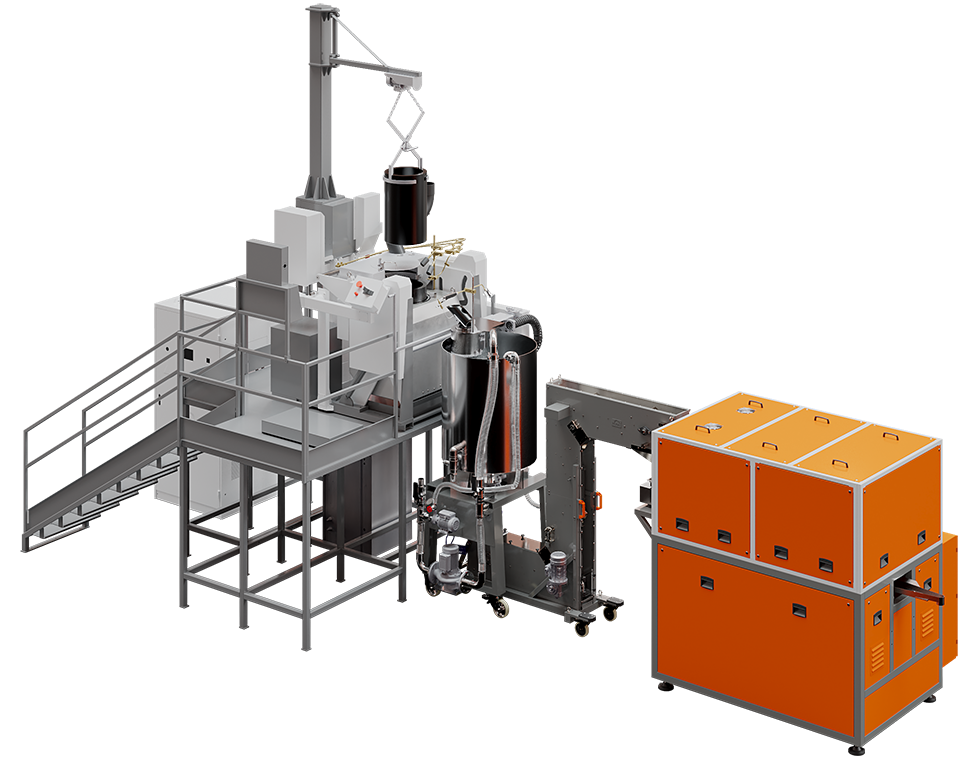

Automated grains production system

T-Grains™ is an automated system designed to produce gold and silver grains of the highest quality, eliminating the risks and slowness of manual work.

A key element of the system is the layout of the plant, which prevents the metal from cooling as it passes through the granulation tank. This is made possible by the presence of a heated casting die, equipped with a dedicated inductor. This ensures that the temperature of the molten metal remains constant, preventing production defects.

Another advantage is the minimisation of the exposure time of the molten metal to oxygen in the air, a crucial factor in achieving a perfect quality shot.

In addition, the temperature of the water in the granulating tank, which is decisive for the final quality of the grains, is controlled by a cooling system connected to a recirculation pump. This system maintains a constant water temperature in each granulation batch, ensuring uniformity in the process.

T-GRAINS™ CONSISTS OF:

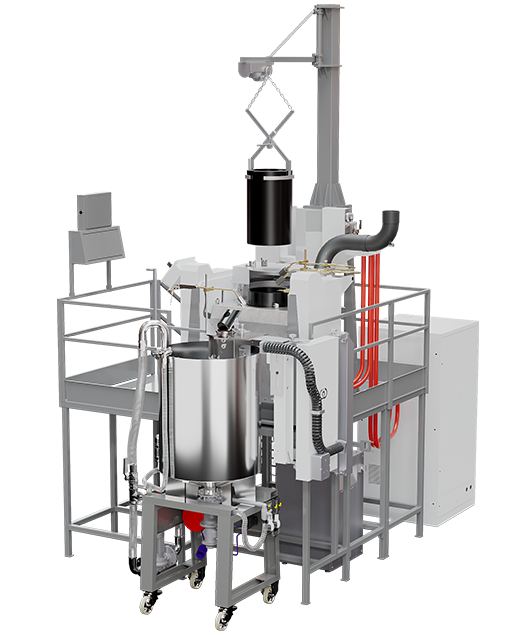

- A tilting furnace, operator-controlled via joystick.

- An induction heated die, designed to prevent the melting temperature reached by the metal from dropping as it passes through the granulation tank.

- Stainless steel, temperature-controlled graining tank connected to a cooling system by means of a water inlet and recovery pump.

- Double Pinch Valve invented by Tera for automatic grain transfer to the T-Lift™.

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Automation

The pouring of molten metal into the graining tank occurs semi-automatically through the use of fixed or wireless control devices, without direct interaction between operator and crucible.

02

Less dispersion

Almost no heat loss, as the metal recovers heat from the heated die and immediately comes into contact with the water inside the graining tank.

03

Speed

Higher working speed.

04

Quality

Top-quality grains free of oxygen particles.

MODELS

| Dimensions | 5000x4000x3500 mm |

| Weight | 2600 Kg |

| Power | 60 kW |

| Grain production per hour | 200 Kg Ag / 400 Kg Au |

| Metal | Melting time | Casting time | Drying time |

|---|---|---|---|

| 250 g Ag | 45’ | 15’ | 45’ |

| 250 g Au | 45’ | 15’ | 30’ |

| Dimensions | 5000x4000x3500 mm |

| Weight | 2700 Kg |

| Power | 100 kW |

| Grain production per hour | 300 Kg Ag / 600 Kg Au |

| Metal | Melting time | Casting time | Drying time |

|---|---|---|---|

| 250 g Ag | 50’ | 15’ | 45’ |

| 250 g Au | 45’ | 15’ | 30’ |

TECHNOLOGY

HOW DOES T-GRAINS™ MACHINE WORK?

01

The fine metal reaches its melting point in the tilting furnace.

02

The operator, through the joystick, pours it into the graining tank.

03

The metal is poured through a heated isostatic graphite die, designed so that the metal does not drop below its melting temperature before contact with the cold water inside the graining tank.

04

Grains produced settle at the bottom of the graining tank.

05

There is no need to empty the graining tank: the grain is discharged by the opening of the Double Pinch valves in synchrony with the movement of the T-Lift™ bucket conveyor belt.

TAILORED AUTOMATION

AUTOMATION FOR SUPERIOR QUALITY GRAINS

Each Tera Automation machine can be conceived as part of a modular line which can be combined according to the company's needs and facility space. Each machine can be fitted to existing machines and a full line can be developed over time.

T-Grains™ was designed with the purpose of producing flawless grains intended for ingot casting, and can be combined with other machines, according to each operator's specific needs.