Over the past year, Tera Automation has ramped up innovation, developing solutions that meet the growing demands of the Good Delivery bar market.

In 2018 Tera Automation introduced to the world the first-ever T-Line, a groundbreaking solution for the automated production of precious metal ingots. A spark of intuition that changed the course of the industry, bringing it to an unprecedented level of automation, especially at the melting and finishing stages of ingot production.

For the third consecutive year, we are pleased to promote the T-Talent initiative, a merit-based scholarship dedicated to recent high school graduates interested in pursuing a university path in the STEM field.

For over a year, Tera Automation and Doma Automation have been collaborating to bring innovative solutions to the field of industrial automation and precious metal processing.

At the prestigious 49th IPMI Annual Conference, we had the pleasure of presenting an automation technology that we confidently describe as "disruptive": the T-Sintermint Line.

The beginning of Industry 5.0 redefines the role of machines as collaborative partners able to support and improve human skills.

Infinifeed™ is a power system - featuring integrated App - for products of different shapes weighing.

To be placed on the market, ingots must meet specific quality standards, especially regarding purity and weight; also, they must carry specific information about traceability.

A great architect once invented the “less is more” concept to suggest that, at the project stage, you should always choose minimalism over complexity.

2023 is running out. It’s time to look back at what we have done and set our sights to future challenges and opportunities. This article aims to give an overview of the events that marked our 2023, just in case you missed something along the way.

Among the many innovations that are making robot islands increasingly efficient and high-performance, Bin Picking is undoubtedly one of the most interesting.

For industrial design in general – and for the precious metals sector in particular – digital processes and tools are increasingly important. These resources, in fact, offer the possibility of increasing the level of detail of the project and carrying out real simulations.

Known since ancient times as a tool for writing and decorating, graphite is a black carbon-based crystalline solid that occurs in nature in various forms, including flat hexagonal crystals and amorphous particles.

As we know, 2035 will mark the beginning of the green electric vehicle revolution and will thus be a turning point for the metal market.

It was 1959 when industry and civilization saw for the first time a robot replace man in the strenuous tasks of the General Motors assembly line. That day marked the incipit of an increasingly automated and optimized production in which robots became protagonists.

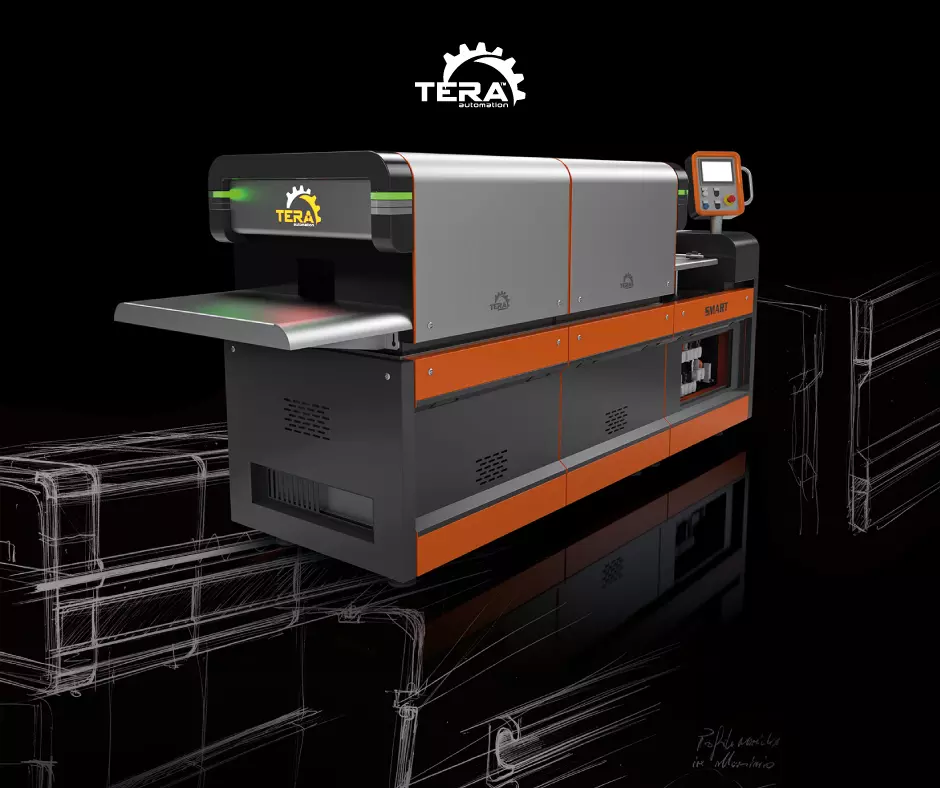

Our T-BarmasterTM tunnel furnace is the flagship of the Tera catalogue. The process which led us to revise its exterior was very natural and a direct consequence of our customers’ great passion for this product.

From large steel mills to small goldsmith companies, the foundry plays a central role in the quality of the products introduced into the industrial and commercial circuit. And when we talk about casting, it is linked to a harsh work environment, with high temperatures and the need for special Personal Protective Equipment to prevent any type of risk.

In practical and investment terms, automating a manufacturing facility by purchasing robots or new digitized and networked machinery almost always involves a relatively large outlay. However, the move toward industrial automation can also be less costly.

Tuscany, our land of origin and where Tera Automation is based, is the cradle of leather accessories manufacturing. This long-standing tradition began in the mid-nineteenth century in artisan workshops. The modern and innovative turning point came thanks to Guccio Gucci, founder of the homonymous fashion house, and it is thanks to this evolutionary path that the latest generation of robotic cells can really make the difference in the production line of leather and leather accessories and items.

The quality control of a company is a useful tool to prevent any kind of problem that could occur on the finished product. The processes of quality control are also functional to the management of relationships with suppliers, called to ensure the quality standard required to meet, and satisfy as much as possible, the demands of customers.