INGOT, ANODE AND ROD PRODUCTION MACHINES

Over the years, Tera Automation has gained solid expertise in designing and manufacturing furnaces dedicated to the production of ingots, anodes, and rods in precious metals.

The most important companies in the sector, specializing in the production of investment ingots, choose our furnaces for their ability to operate continuously 24/7, offering constant reliability even with high production loads.

As with all machines made by Tera Automation, our furnaces are also designed with a particular focus on automation, ensuring optimal integration within production lines.

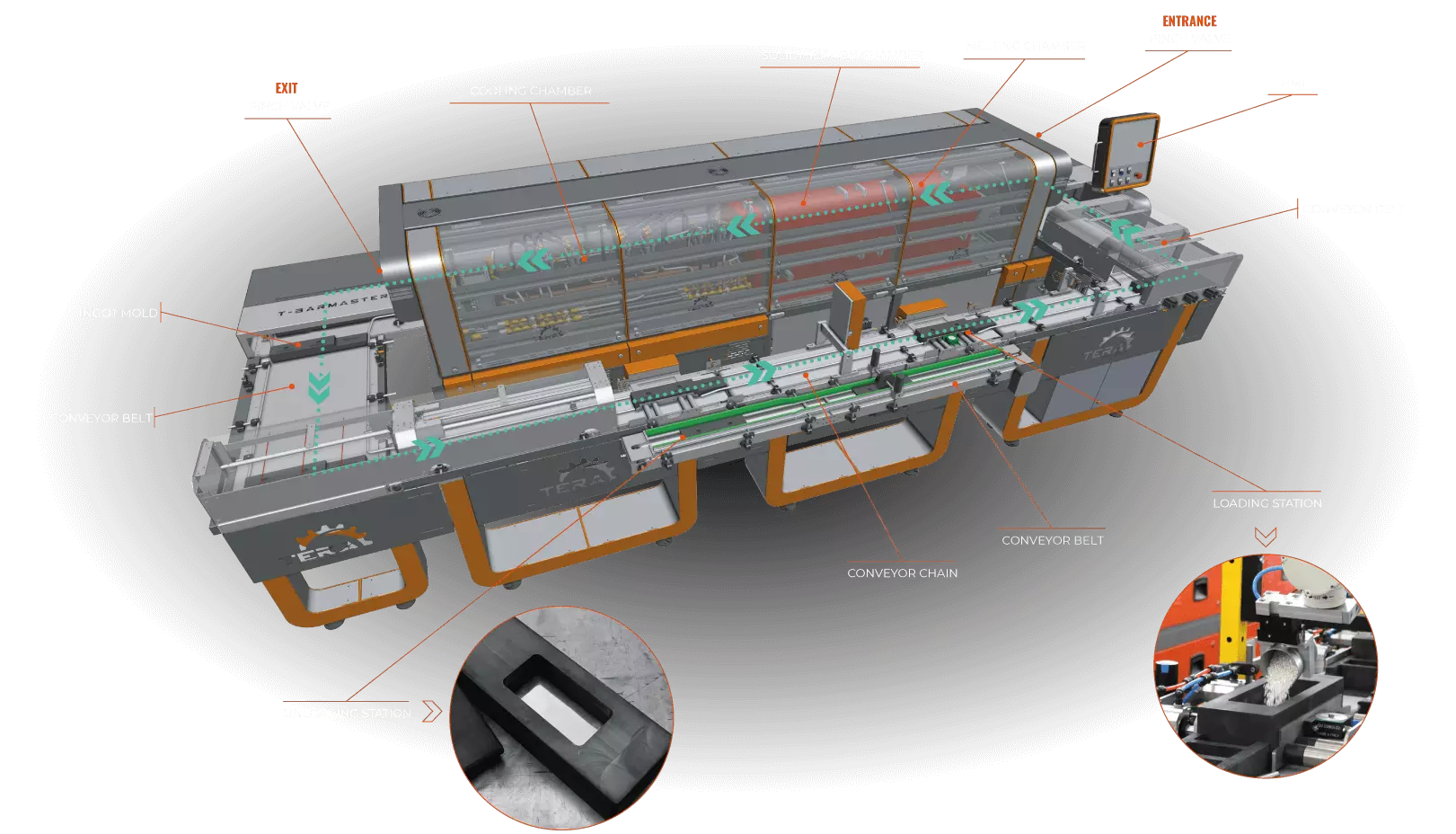

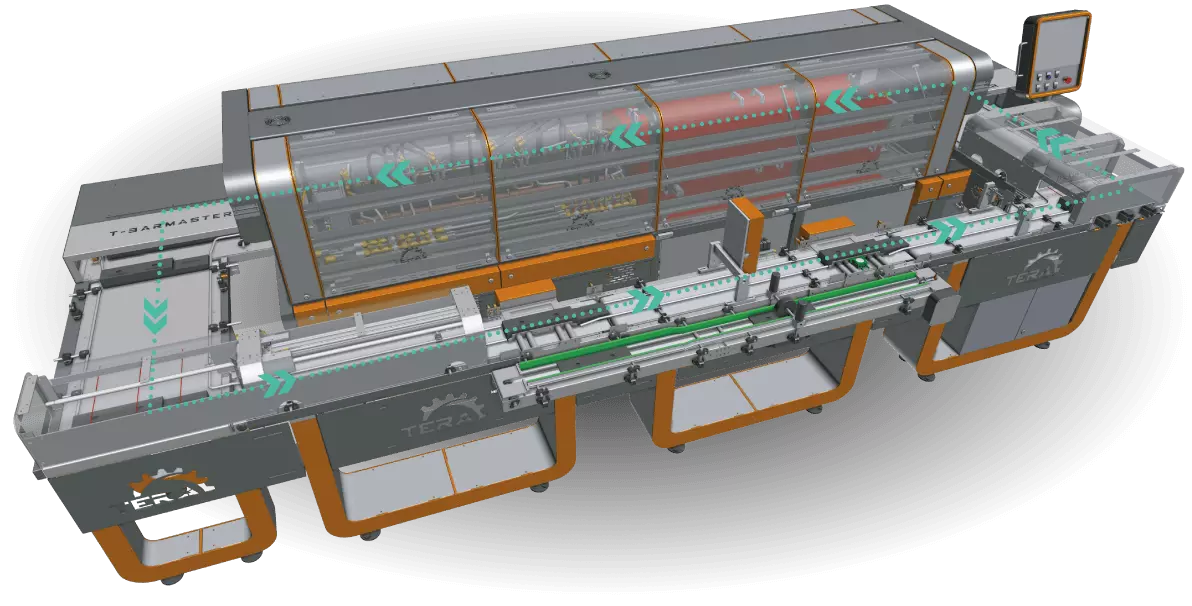

T-BARMASTER

The flagship of Tera Automation is the T-Barmaster induction tunnel furnace line, especially designed for the production of perfectly flat ingots with an impeccable mirror-like surface.

These furnaces represent the core of our business, the result of years of concentrated expertise and advanced research. T-Barmaster™ furnaces combine flexibility and ease of use with highly advanced technology, and they are entirely designed, managed, and assembled by Tera Automation.

With T-Barmaster™, we have transformed the industry, offering companies worldwide customizable tunnel furnaces capable of adapting to various production needs, from 1-ounce ingots to 1000-ounce ingots. Additionally, maintenance has been designed for easy accessibility, thus meeting the needs of users.

MODELS

There are several furnace models, differentiated by the type of ingot produced, the type of metal to be melted, and energy efficiency:

T-BARMASTER

STANDARD

Induction tunnel furnaces for the production of ingots from 1 ounce to 1000 ounces

T-BARMASTER

SUSTAINABLE GOOD DELIVERY

Energy-saving tunnel furnaces for the production of Good Delivery ingots

T-BARMASTER PT-PD

Vacuum tunnel furnace for continuous production of PGM/Au/Ag bars

T-Barmaster Pt-Pd is a vacuum tunnel furnace designed for the continuous production of platinum, palladium, and other precious metal ingots.

Thanks to an advanced vacuum melting system, the furnace eliminates typical issues related to oxidation and trapped gases, ensuring ingots that are perfectly free of imperfections.

The machine reaches temperatures of up to 2100°C, allowing different types of metal to be melted into various shapes, including crystals.

Its high level of automation enables efficient and safe production with consistent quality, making the system also suitable for melting gold and silver.

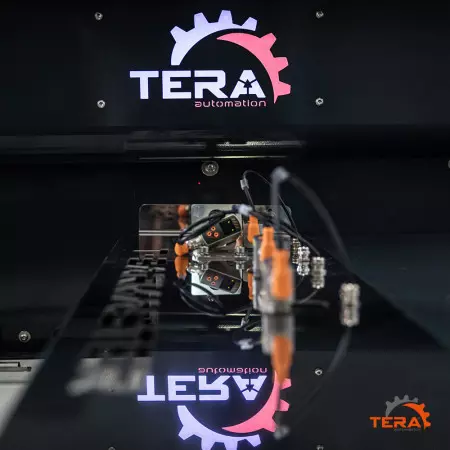

T-CONVEYOR CAST

Automatic ingot casting machine to produce precious metal anodes and bars

T-Conveyor Cast™ is a system designed for companies casting anodes and bars in precious and non-precious metal. As a matter of fact, this ingot casting machine can be combined to tilting melting furnaces with both vertical and horizontal casting, working with different types of molten metal: gold, silver, copper, brass, zinc, aluminum, etc.

We designed it specifically to lighten the burden of operators' manual workload - just think of the heavy weight of cast iron ingot molds alone - and to drastically reduce risks at work due to the proximity to furnaces. This is made possible by using a pushbutton panel (also available in a wireless version), which allows operating tasks at a safe distance.

Once you add the T-Conveyor Cast™ to your company's production flow, you will immediately perceive how much the pace of production of anodes and bars increases.

TECHNOLOGY

HOW DOES THE T-BARMASTER TUNNEL FURNACE WORK?

All T-Barmaster induction tunnel furnaces share a structure that includes the three standard processing phases through which the metal—grains, flakes, or powder—must pass to become an ingot.

Melting, solidification, and cooling.