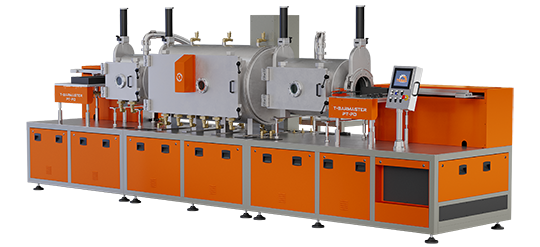

T-BARMASTER PT-PD

Vacuum tunnel furnace for continuous production of PGM/Au/Ag bars

T-Barmaster Pt-Pd is a vacuum tunnel furnace designed for the continuous production of platinum, palladium, and other precious metal ingots.

Thanks to an advanced vacuum melting system, the furnace eliminates typical issues related to oxidation and trapped gases, ensuring ingots that are perfectly free of imperfections.

The machine reaches temperatures of up to 2100°C, allowing different types of metal to be melted into various shapes, including crystals.

Its high level of automation enables efficient and safe production with consistent quality, making the system also suitable for melting gold and silver.

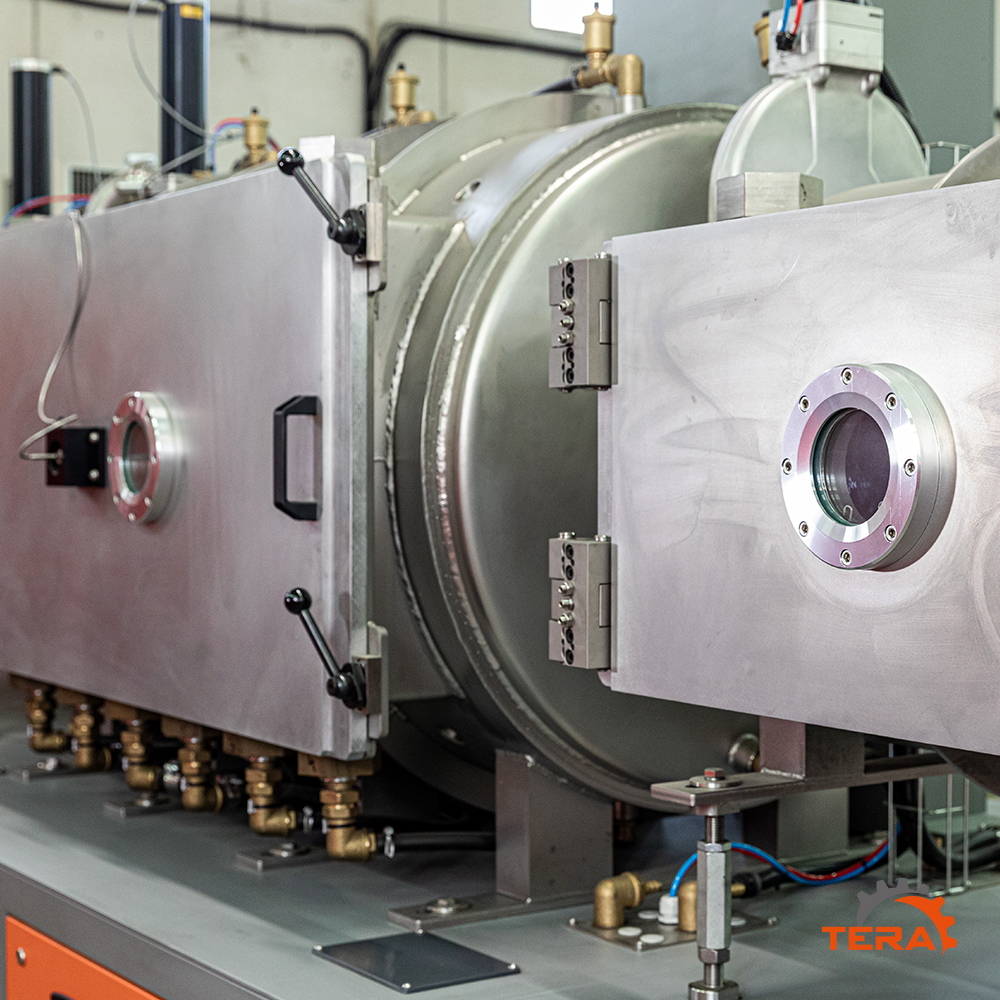

T-BARMASTER PT-PD CONSISTS OF:

-

Vacuum pump system for regulating the pressure of the airlock chambers.

-

Loading tray: area for the manual positioning of the ingot molds.

-

Entry airlock chamber: through the action of the pump, the chamber can vary its pressure from ambient pressure (when receiving material from the outside) to high vacuum (when advancing the metal into the melting area).

-

Process chamber: vacuum chamber where the melting, solidification, and cooling of the metal take place in sequence.

-

Exit airlock chamber: operates in the same way as the entry airlock chamber and also contributes to further cooling of the metal.

-

Unloading tray: area where the ingot molds containing the finished ingot are retrieved.

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Automation

Continuous production of Pt/Pd ingots in a protected and controlled process, with minimal operator involvement.

02

Versatility

Operating capability up to 2100°C to melt any metal shape.

03

Quality

Melting and solidification in a vacuum environment without gas inclusions, ensuring uniform and bubble-free ingots.

04

Efficiency

Longer consumable lifespan thanks to the absence of oxidation.

| Furnace dimensions | 6000 x 1300 x h2100 mm |

| Pump dimensions | 1100 x 1000 x h1400 mm |

| Weight | 400 kg |

| Max. power absorbed | 70 kW |

| Converter power | 60 kW |

| Productivity for 50oz Pt | 8-10 pcs/h |

| Productivity for 100oz Pd | 4-5 pcs/h |

--

TECHNOLOGY

HOW DOES T-BARMASTER PT-PD WORK?

01

First, an operator loads the ingot mold on the input tray in the loading area. Meanwhile, the first airlock is pressurized by inert gas until atmospheric pressure is reached. Once the same level of pressure between the outside and inside is ensured, guillotine valve No. 1 opens, allowing the ingot mold to pass from the loading tray to the thrust chamber.

02

As soon as valve No. 1 has closed, the vacuum pump system generates the required vacuum inside the thrust chamber until the same pressure level is reached as in the melting chamber.

03

At this point, the second guillotine valve opens, and the ingot mold is pushed into the process chamber, where melting, solidification and cooling of the metal occur in sequence.

04

Then, guillotine valve No. 3 opens: the ingot mold moves onto the movable plate, located next to the cooling tunnel in the exit chamber. The latter is pressurized by inert gas to the same pressure level of outside.

05

At this stage, guillotine valve No. 4 opens. The ingot mold advances to be removed by the operator from the exit tray. Meanwhile, valve No. 4 closes, vacuum is generated inside the chamber: a new production cycle begins.