T-LINE

THE ONLY FULLY AUTOMATED PRODUCTION LINE IN THE WORLD FOR THE CONTINUOUS PRODUCTION OF GOLD AND SILVER INGOTS

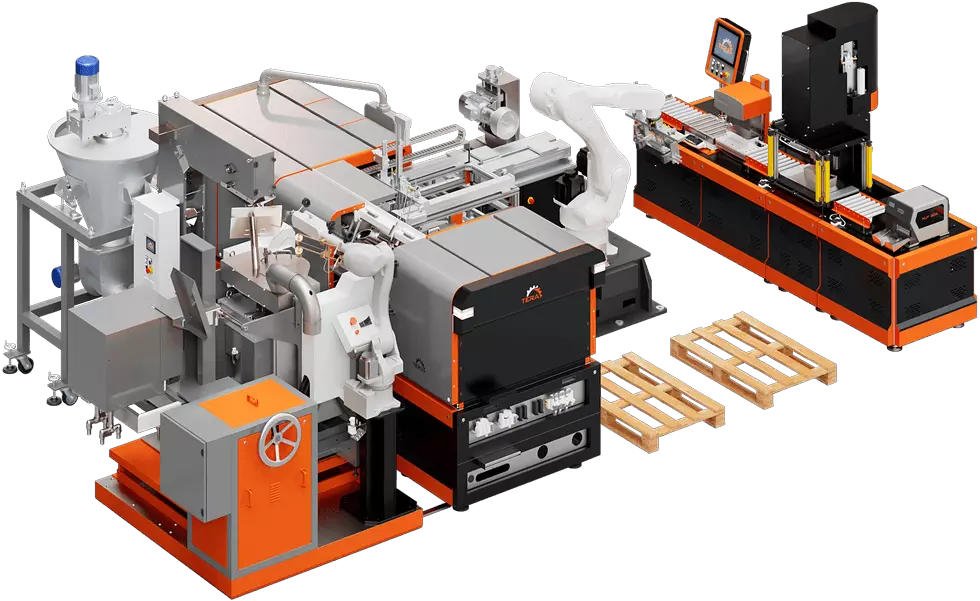

T-Line™ is the first module production line in the world that can manufacture precious metal bars in a fully automated way. It includes all specific units necessary to carry out each production step and shows a high degree of flexibility and customization.

Each operation is carried out in a sequence one after the other, as the product moves along the production flow; the production line modules can be combined and modified according to specific process requirements.

THE PROCESS

Ag crystals

T-Hopper Crystals & T-Lift High Special

IT-Onecast

Solified Good Delivery Bars

T-Robot

T-Satin Brite

Satin bars

T-WM Plus

Serialized bars

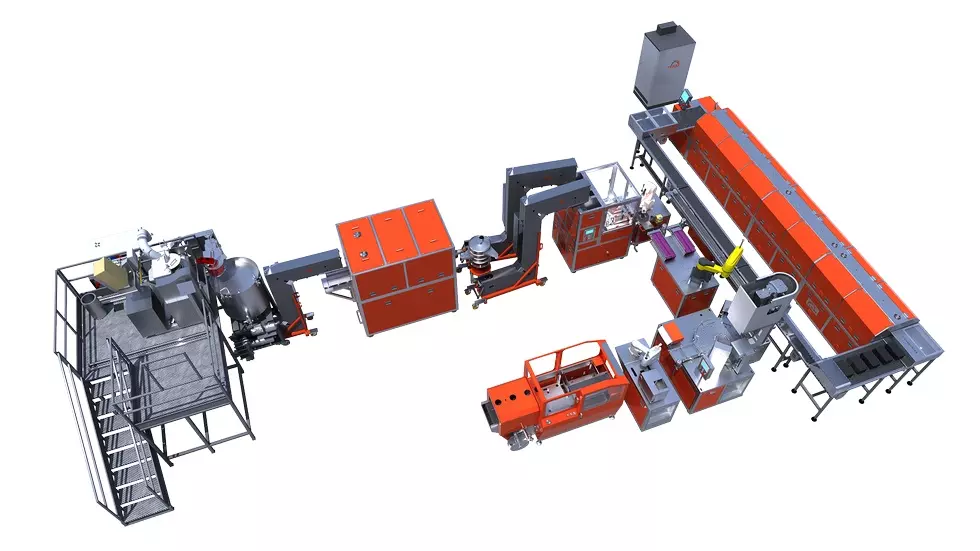

THE PROCESS

T-Dosing

T-Barmaster Powerloop

T-Finishing

T-Pack

THE PROCESS

T-Grains

T-Dryray

T-Dosing

T-Barmaster Powerloop

T-Finishing

T-Pack

ADVANTAGES

10 GREAT ADVANTAGES

INNOVATION AND VISION

The Birth of the T-Line

Erasmus of Rotterdam once said "the best ideas do not come from reason, but from a lucid visionary folly". When we imagined the T-Line, we pushed the limits, designing the world's first fully automated line for the production of gold and silver bars. An ambitious challenge that we turned into reality.

AUTOMATION FOR ALL

In the traditional precious metals industry, we introduced industrial automation with the aim of achieving the highest quality standards: perfect grains, immaculate ingots, flawless processing. The T-Line, initially designed for industry leaders, has become accessible to medium-sized refiners thanks to its modular and scalable technology.

Each component of the T-Line is in fact a stand-alone product that can be integrated with existing production lines and adapted over time. We have made technological excellence available to companies of all sizes, optimising resources and results.

THE HUMAN FACE

Of automation and industrial robotics

Automation is an essential resource to increase production efficiency and enhance the value of human work. The industrial automation of the T-Line allows us to shift manual labor - once necessary to handle machinery - towards more specialized production activities to which manual labor can bring its own added value.

It took almost two years of hard work to install and implement the first T-Line; during these years, every department of Tera Automation was involved in this project that now belongs to every company worker. This fully automated process actually entails a very important human element: the desire of engineers and technicians to fully express the creativity and great potentials of industrial automation, when applied to a production process.