T-FLEXICELL

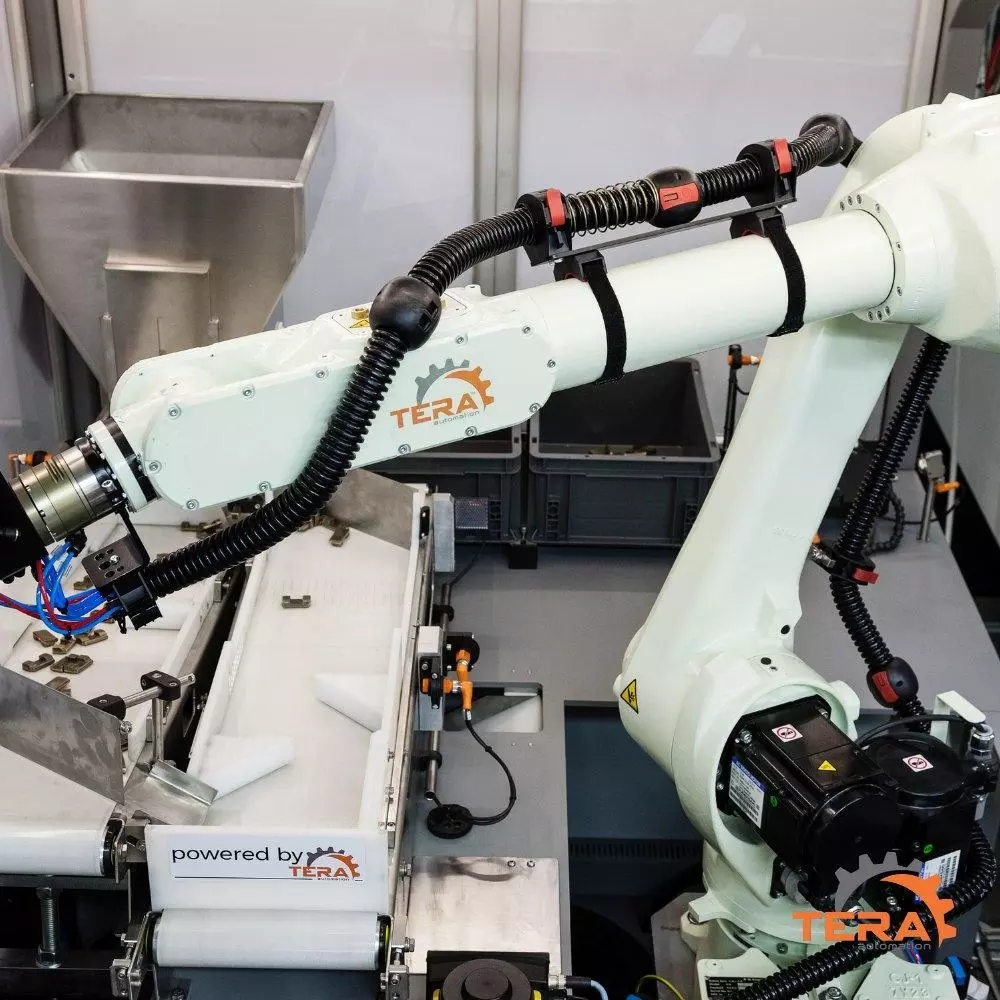

Robotic cell for CNC machine tending

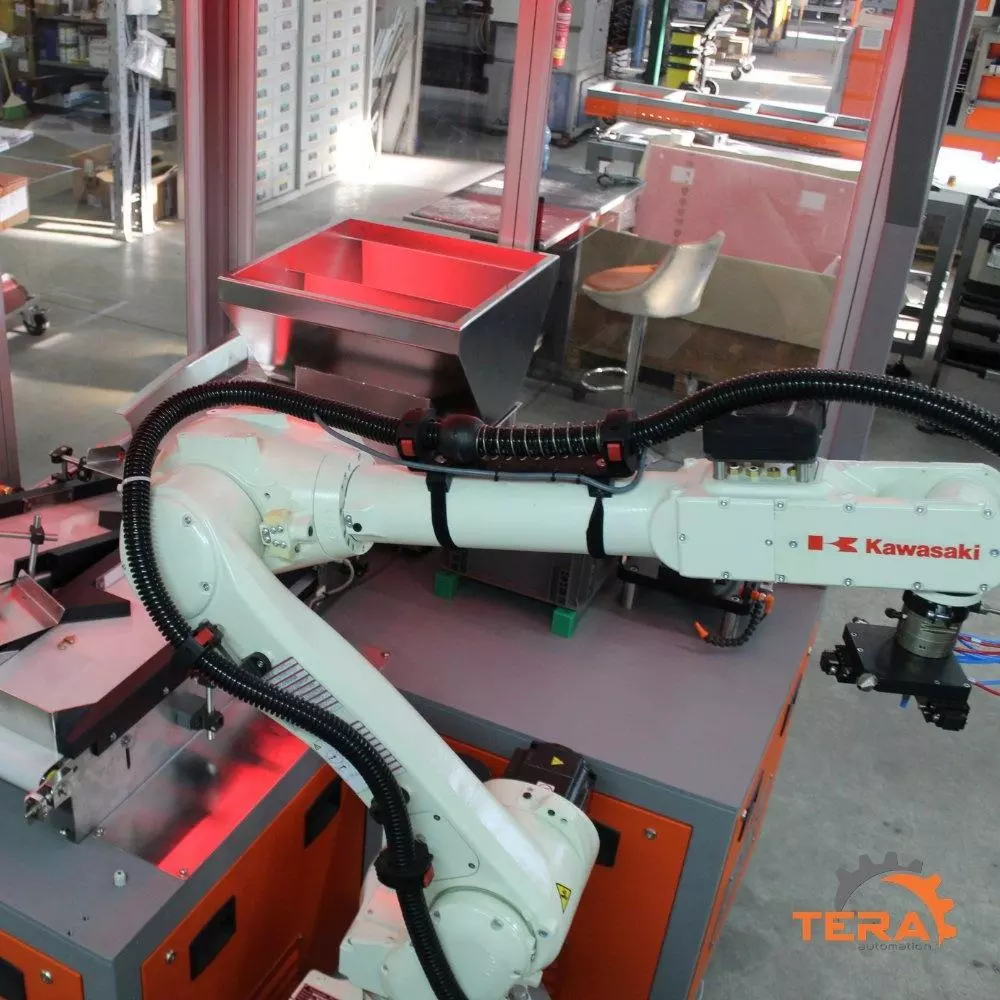

T-Flexicell™ is a robot cell whose purpose is to manage the loading/unloading of components of different sizes. The robotic cell can handle several vises both as part of a single process (the same operation is repeated on several vises), or in a multiprocessing (different operations across several vises).

The most distinctive feature of the range of robotic cells for Computer Numerical Control machine tending called T-Flexicell™ is definitely its flexible application: as a matter of fact, the cell is able to process components with different shapes and sizes thanks to an infeed system which allows loading items randomly.

The purpose of our cells is to maximize CNC machine efficiency and optimize production flow, thus obtaining better performances.

T-Flexicell™ also takes its name from its flexible shape: its compact size is without any doubt a big advantage and, depending on the application type, it can change design according to the specific needs of the sector and the client.

T-FLEXICELL CONSISTS OF:

- Supporting structure equipped with safety interlockingaccess doors;

- Loading area with automated tilting;

- Vibrating hopper for blanks loading;

- Infinifeed: ontinuous closed-loop opposed motionbelts for blanks tilting and aligning;

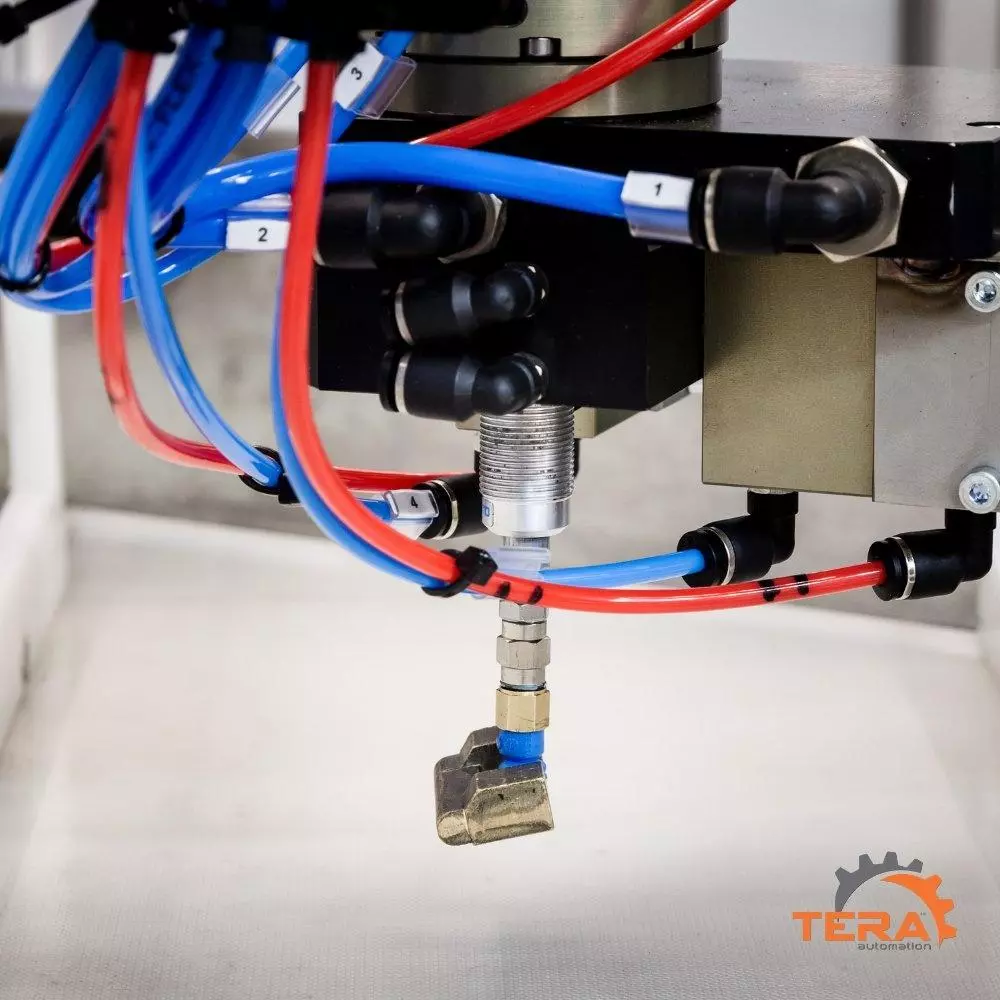

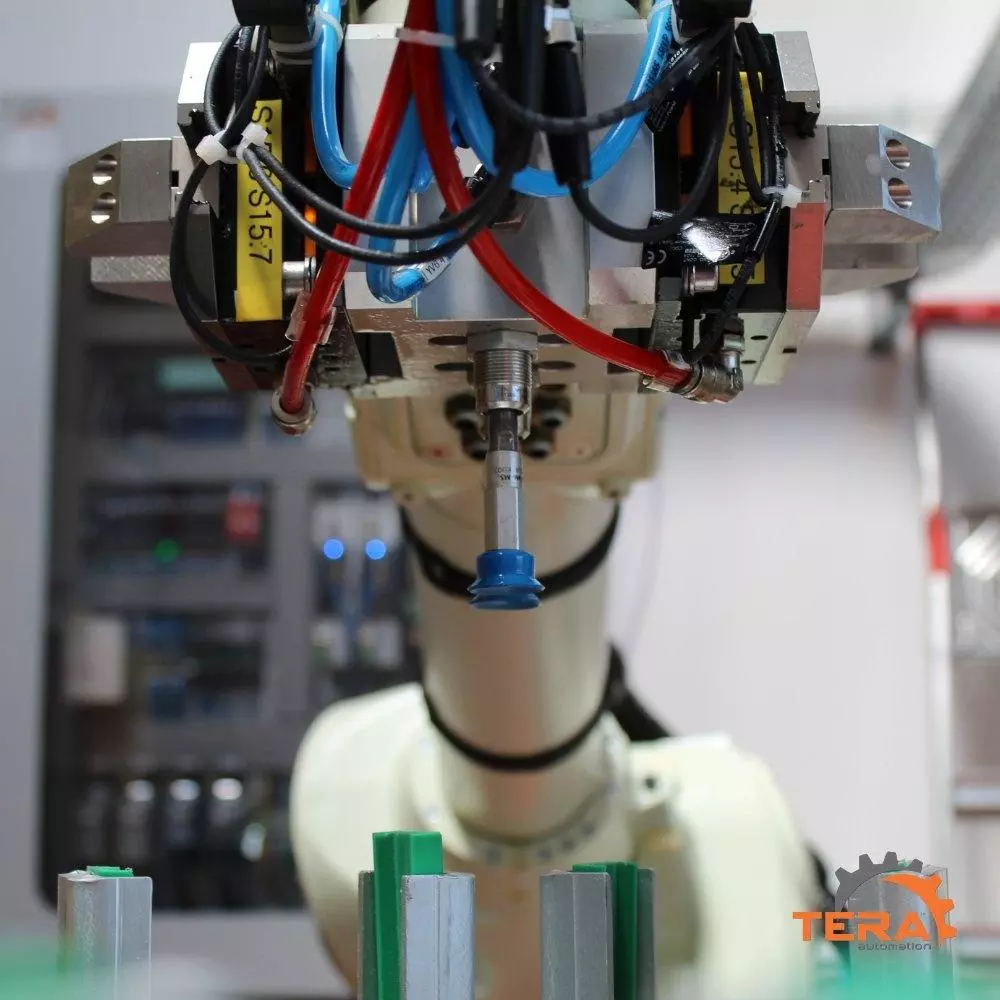

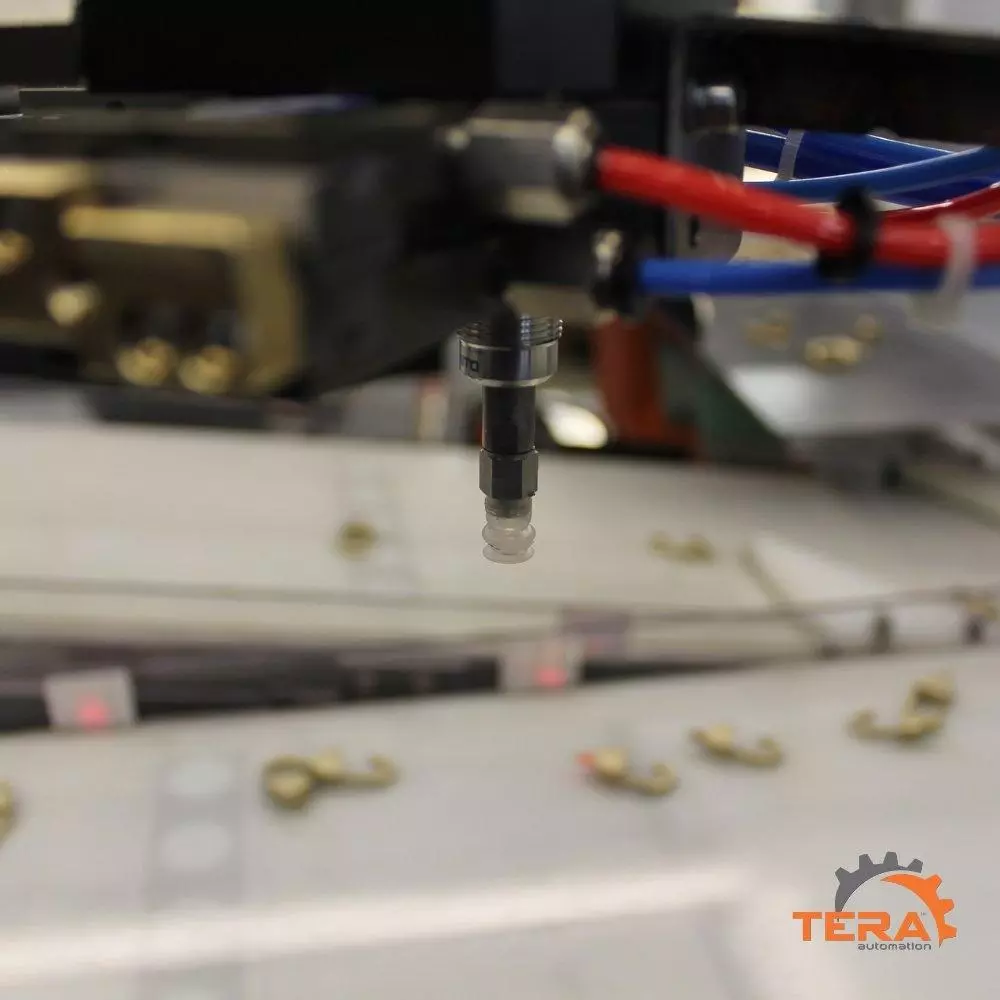

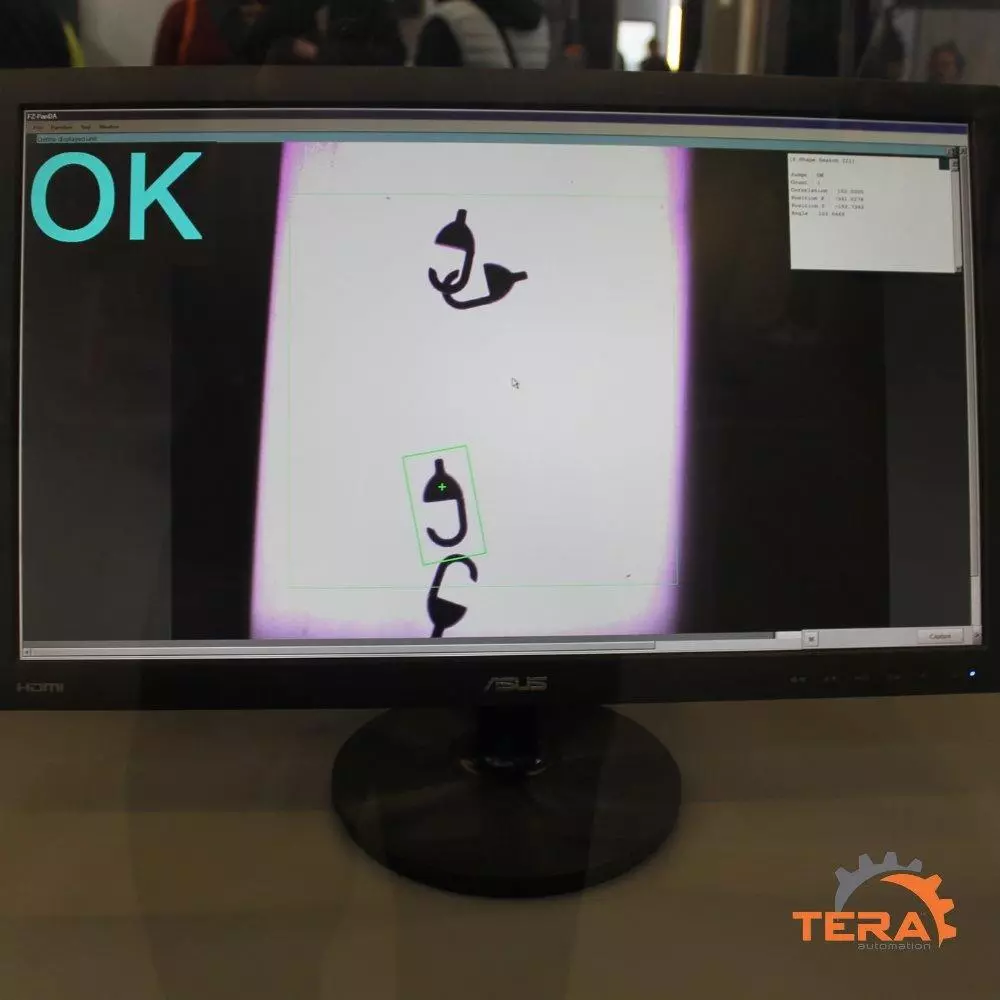

- 2D vision system with infrared backlighting for the detectionand recognition of blanks on a reflective surface;

- 3D vision system for bin picking operations (optional);

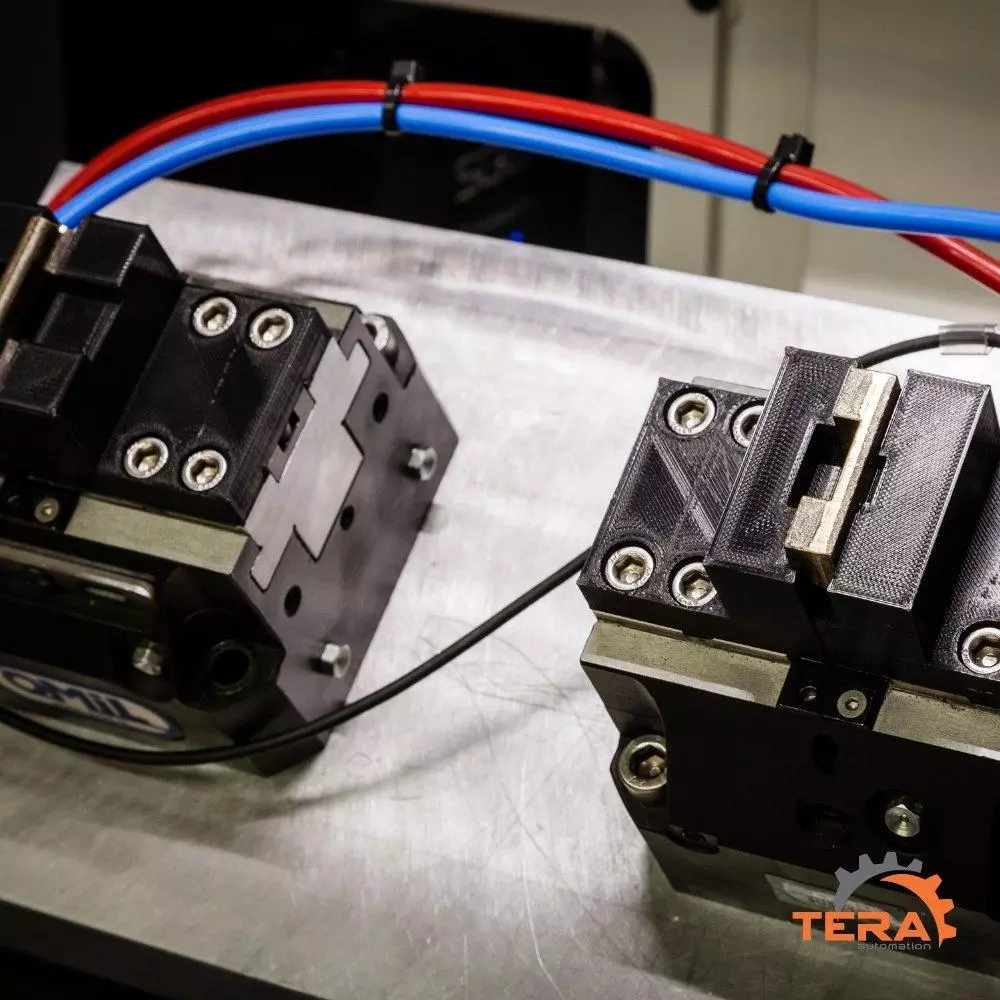

- Multiplace resetting jig for blanks with a sensor to detectthe presence of blanks and a verification system fornon-compliant parts;

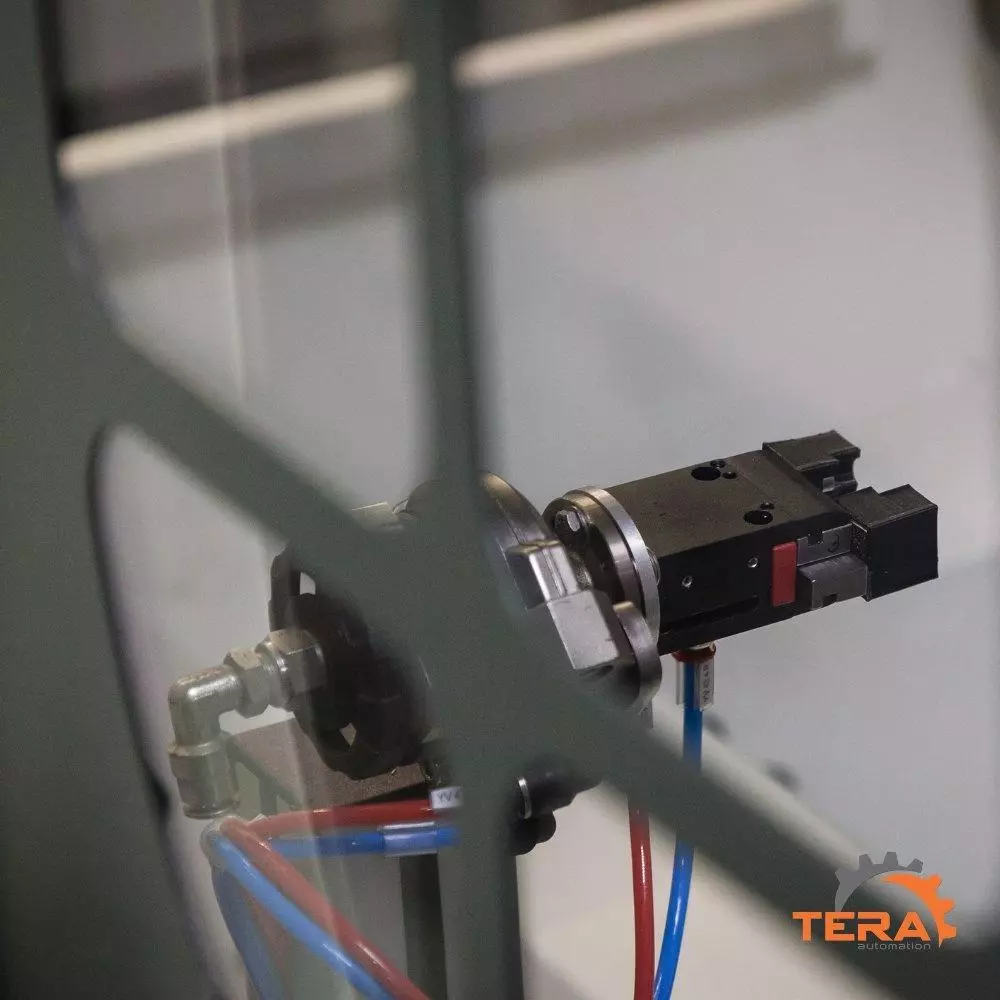

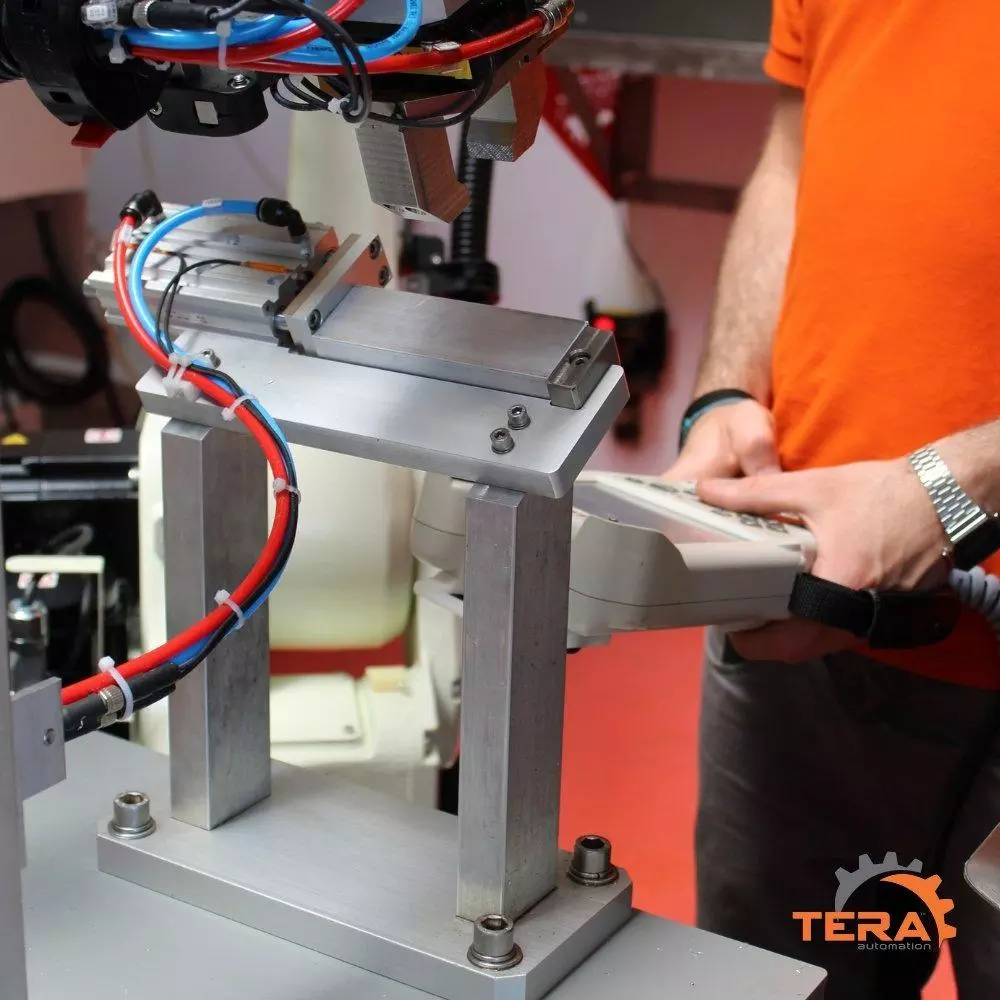

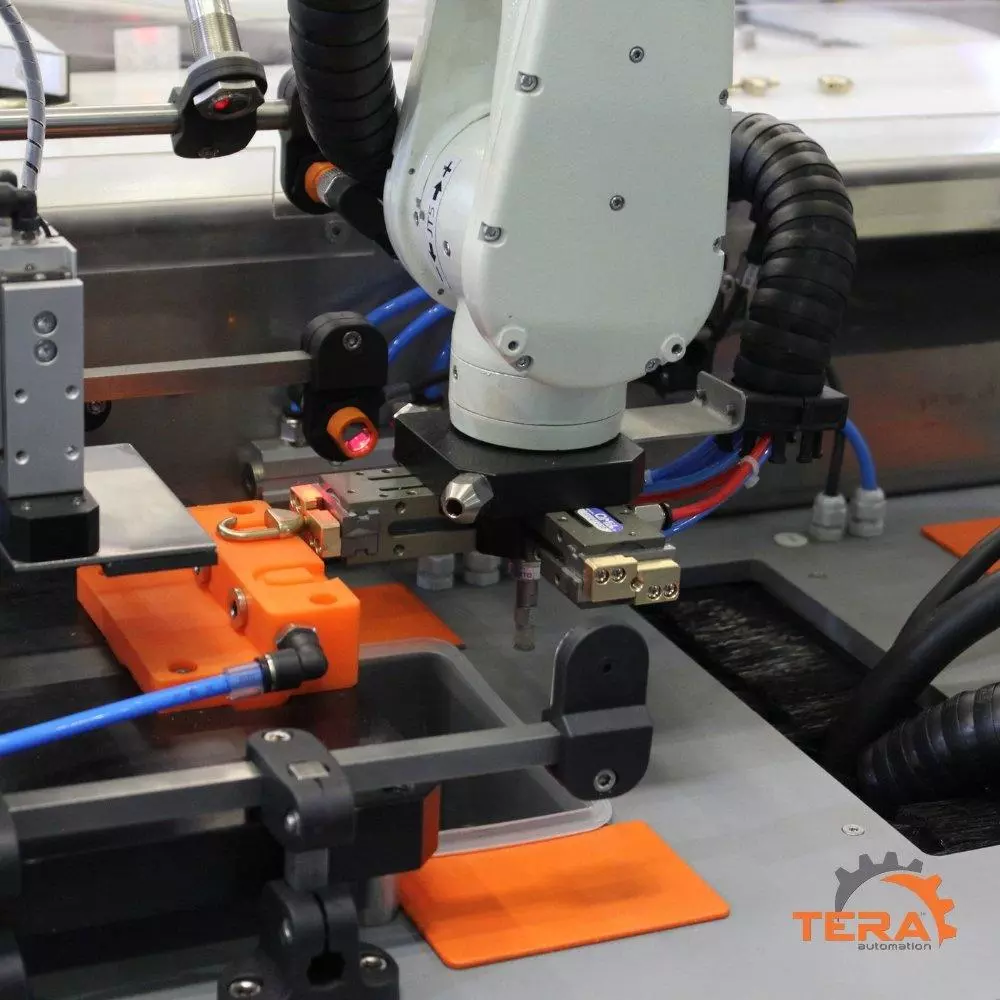

- Anthropomorphic robot equipped with suction cup gripping system and dual gripper for accurate mechanical gripping;

- 2 recovery areas for components (discarded and compliant);

- HMI with a touch screen display;

- Electrical panel fitted with electrical equipment and connections with CNC and Robot.

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Optimisation

Operating autonomy of up to 96 hours, high flexibility and precision in machining.

02

Efficiency

Increased productivity thanks to continuous load/unload management and 24/7 non-stop operation.

03

Safety

It improves the health and safety of operators and the environment.

MODELS

| Dimensions | 1736 x 1736 x h2344 mm |

| Weight | 1500 Kg |

| Autonomy | 96 h |

| Productivity | 1700 pcs/shift |

--

TECHNOLOGY

HOW DOES T-FLEXICELL MACHINE WORK?

01

The operator loads with blanks the container positioned in the loading area with automated tilting.

02

Infinifeed sorts the blanks

03

The robot picks up the blank.

04

The robot places the blank on the multiplace resetting jig.

05

The robot picks up the blank from the resetting jig and loads into the vice of the CNC.

06

The CNC processes the blank.

07

The robot unloads the part from the CNC machine and releases it in the collection area.