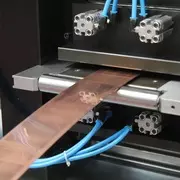

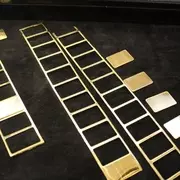

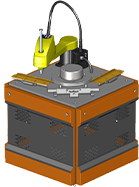

COMPLETE LINE FOR MINTING COINS AND STAMPING BARS

A complete line of machinery and accessories, carefully selected according to the type and quantity of products to be made. From the melting of precious metal and sheet production to the packaging of "proof quality" bars and coins, the T-Minting Line is the ultimate solution for the growing needs of the bullion & refining sector.