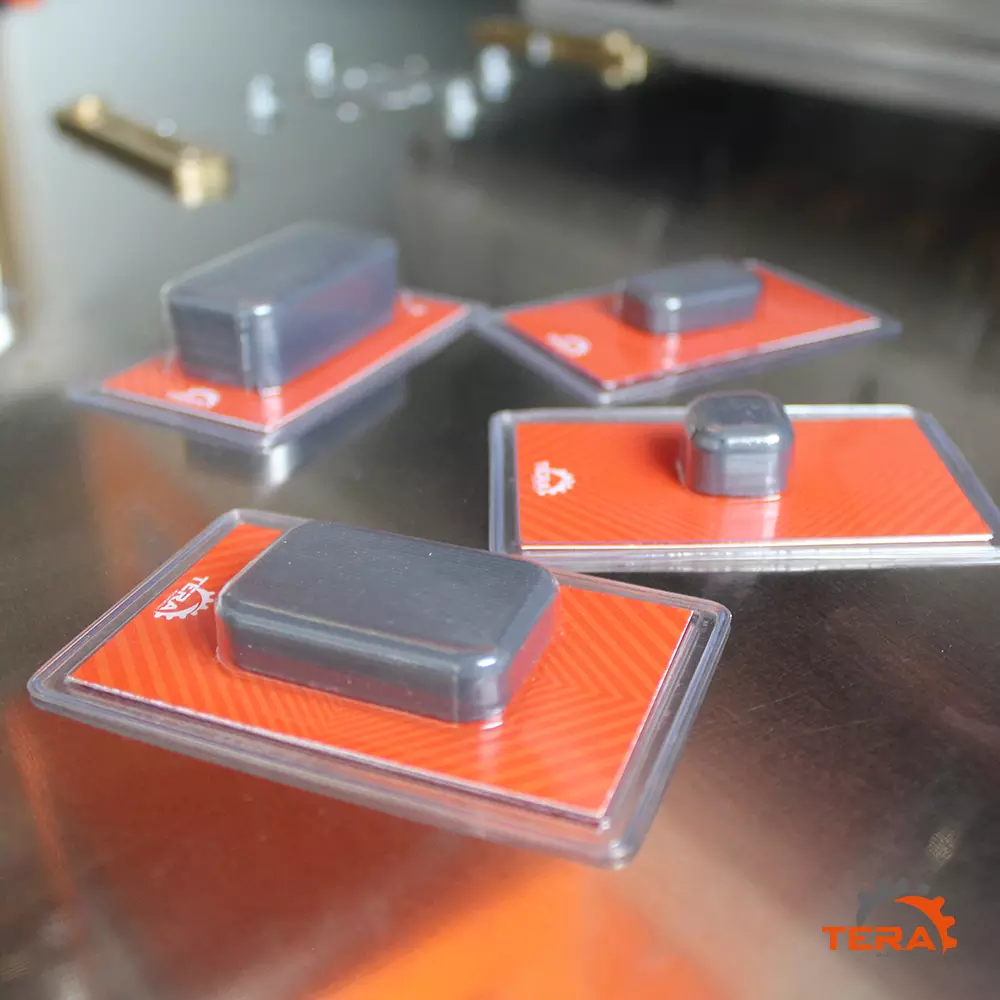

T-BLISTER

Blister machine for ingots and minting

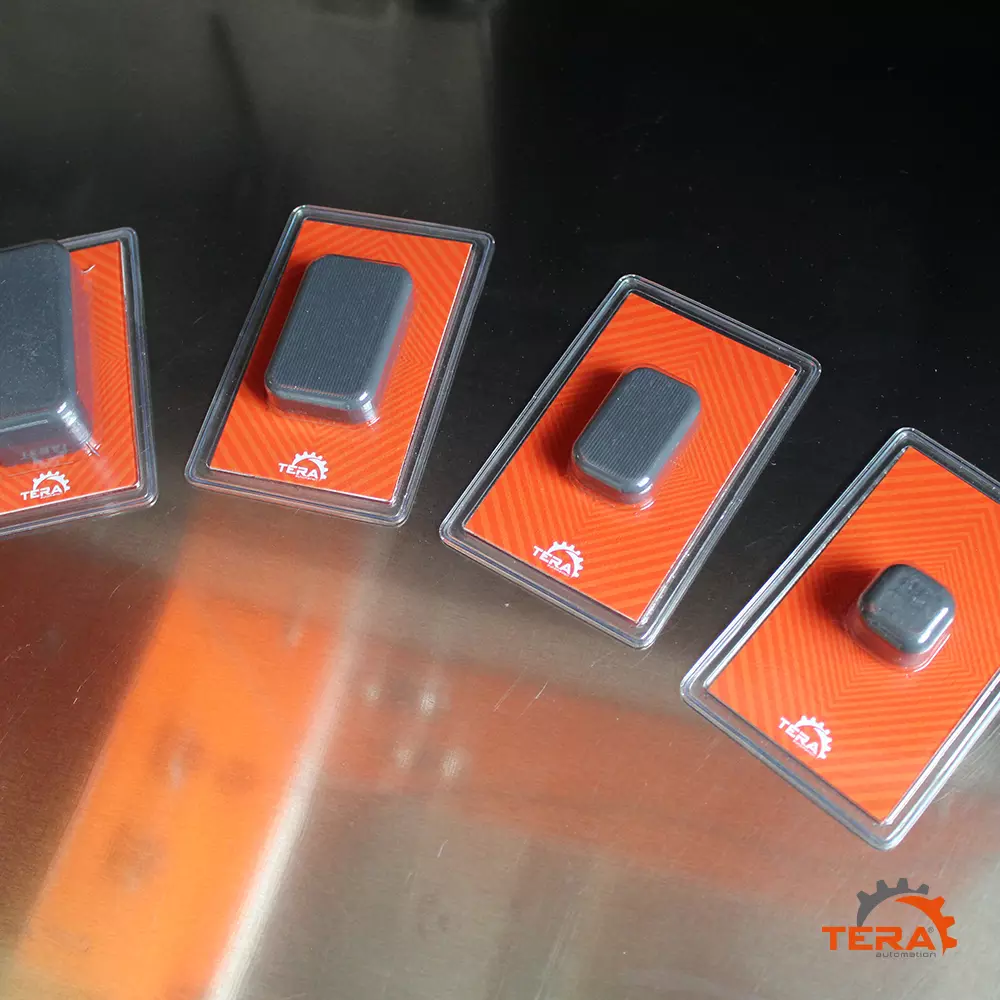

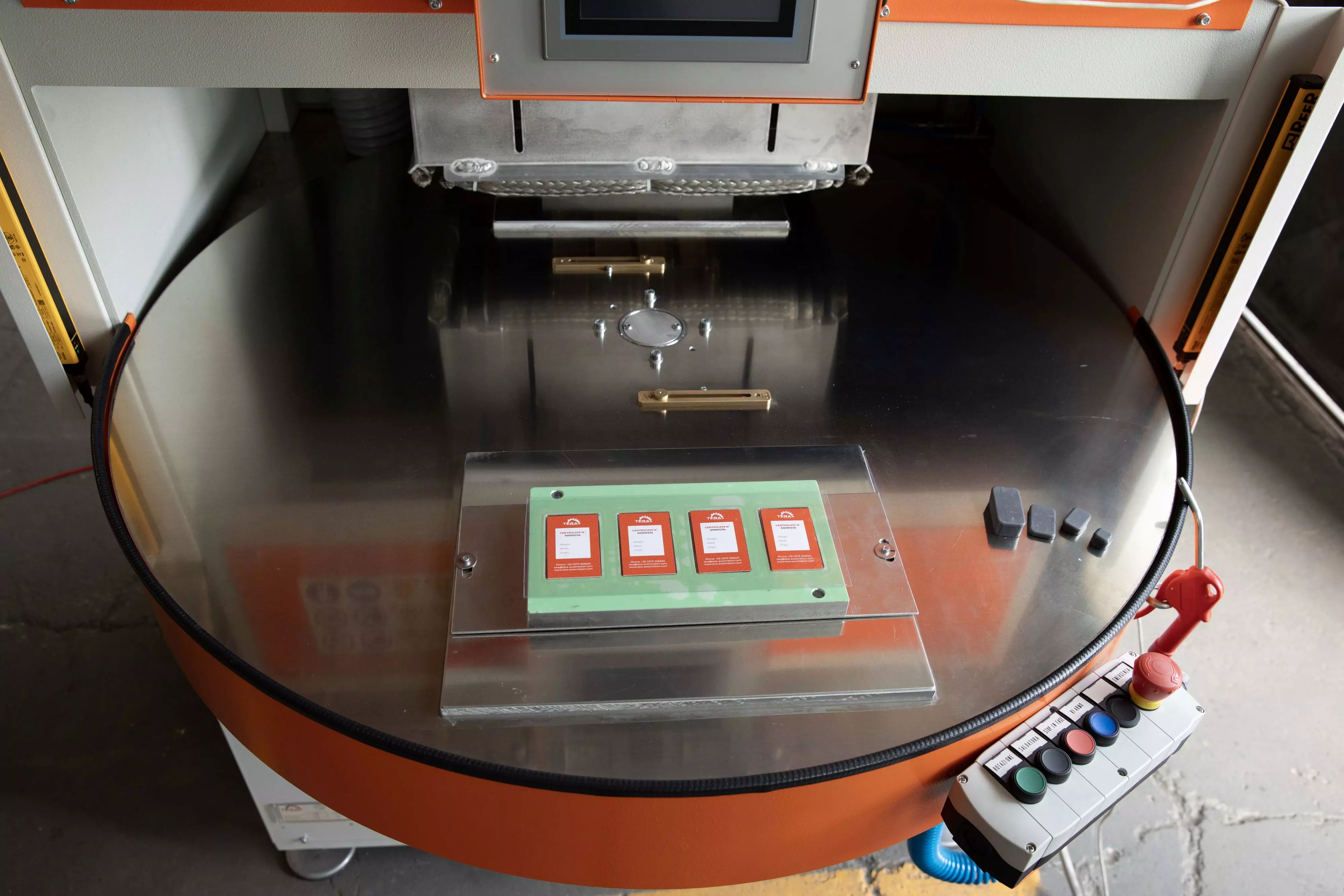

T-Blister™ is a high frequency electric welding machine - for blister packaging of casted or minted bars & coins - with designed system for welding PVC sheets.

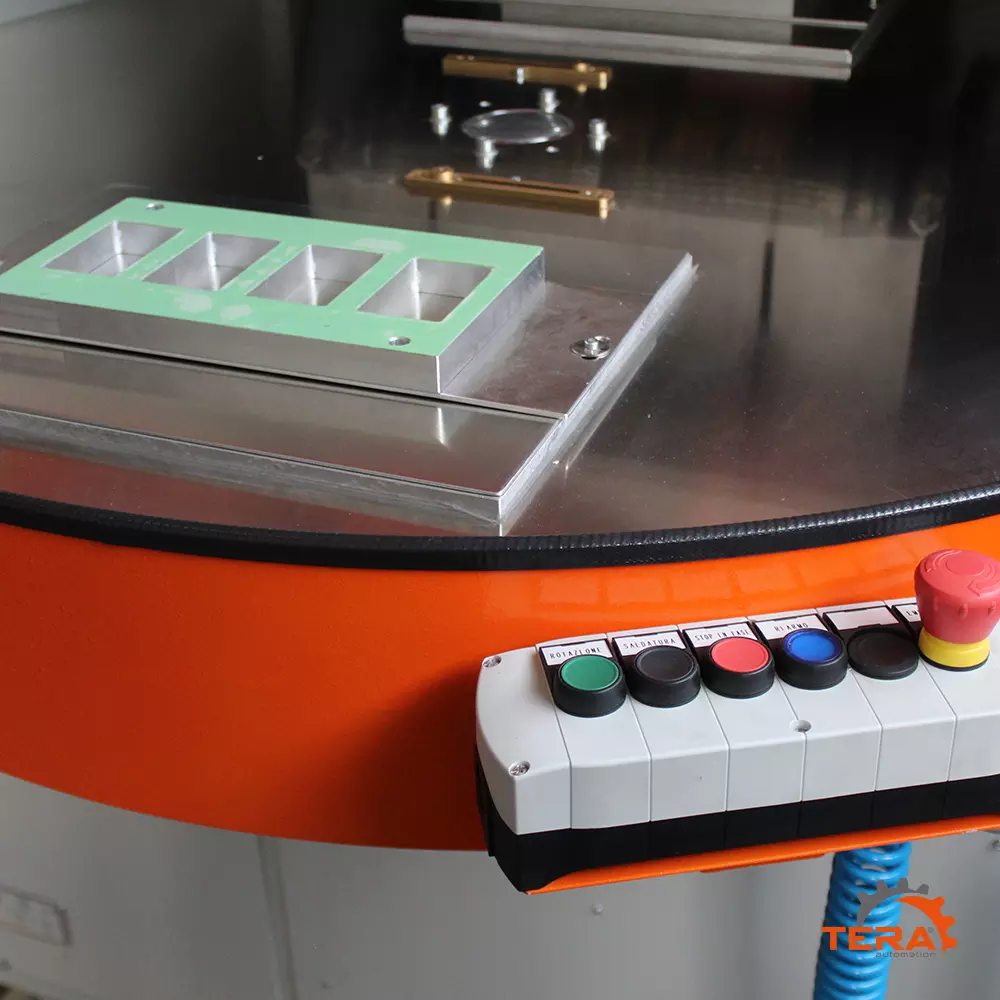

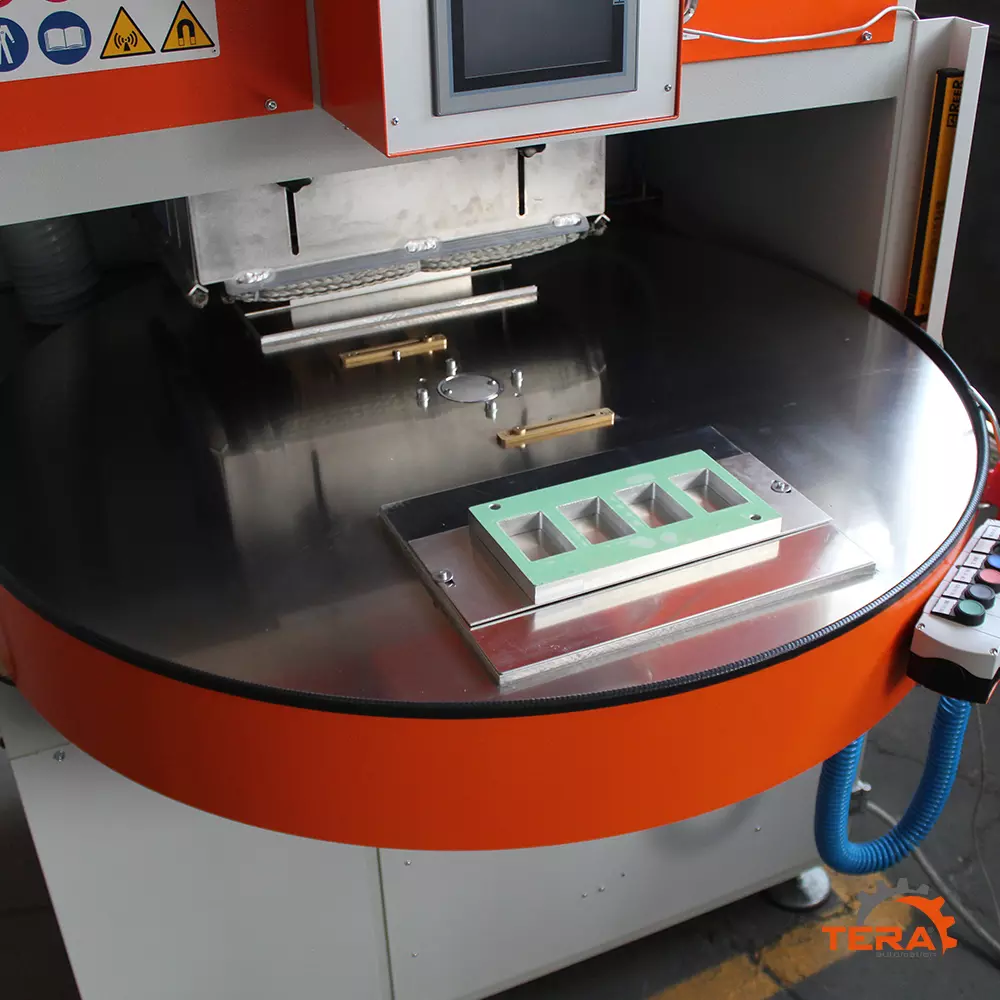

Is provided with rotating table and two working stations (loading/welding) to be operated manually. Easy to use and with excellent reliability, it allows easy handling and repeatability of the package quality. The machine is operated through a microprocessor thereby guaranteeing a high and constant productive speed, assuring an easy and fast man/machine interface.

Final blister can have a single or double welding according to the customer’s requirements (only along the perimeter of the package or also around the product). This provides a great guarantee as it prevents product escapes in case of blister breakage.

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Efficiency

Guarantees consistent high quality of the product with double protection.

02

Practicality

Easy format change.

03

Reliability

Reduced risks and costs.

TECHNOLOGY

HOW DOES T-BLISTER MACHINE WORK?

01

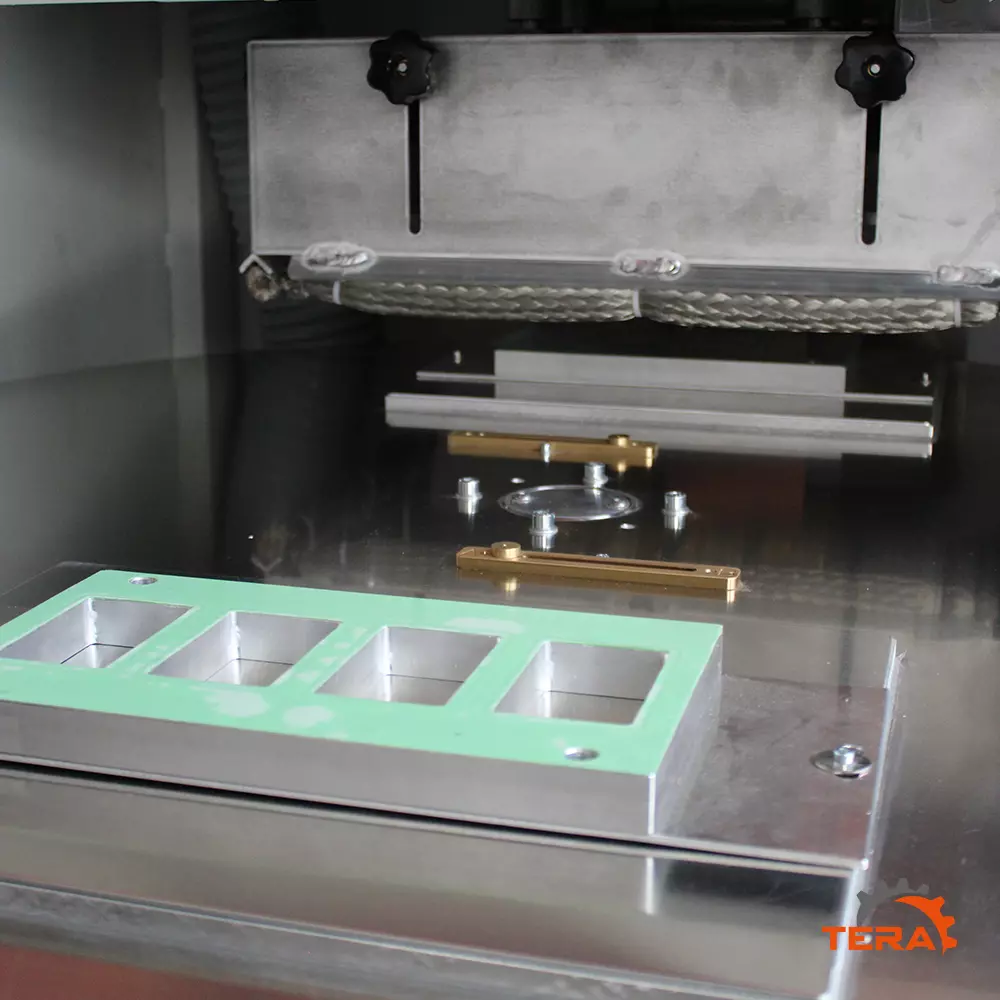

Once the machine is turned on, the packaging cycle is completely automatic. The operator simply puts a pre-shaped PVC bottom sheet on the loading station.

02

Inserts the bars/coins and positions the eventual internal certificate.

03

Finally lays over another PCV sheet.

04

Machine can be started and the loading station moves into the working stage.

05

Packages are sealed; the operator can extract individually welded blisters already separated and ready to be sold.