T-SORTING

Automatic blank coins & bars weight check and sorting.

The 100% precise & accurate weight control in the production process is the only way to optimize the production. In addition, the weighing offers the possibility to divide the coins/blanks in weight classes and so prepare them for a possible material recovery. With T-Sorting, this delicate weighing and sorting process is automated, and the material is sorted into compliant, underweight or overweight.

The weighing process happens with a resolution of 1 mg and with a repeated precision of +/- 2mg. If the measurement shows that the product does not have the desired weight, it will automatically be displaced into the reject area and will not move on to the following production process.

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Efficiency

It automates the selection process, reducing time and improving productivity.

02

Precision

It eliminates manual errors and ensures accuracy in the selection process. Only compliant products move on to the next stages of production.

03

Optimisation

Enables the sorting of coins into weight classes to improve material recovery. Automatically identifies and separates out-of-weight products, avoiding errors in subsequent steps.

MODELS

| Dimensions | 1125 x 925 x 1555 mm |

| Weight | 340 Kg |

| Power | 0,5 kW |

| Productivity | 15/20 pcs/min |

--

TECHNOLOGY

HOW DOES T-SORTING™ MACHINE WORK?

01

Weight setting: the operator defines the weight range of the compliant blanks via the HMI panel.

02

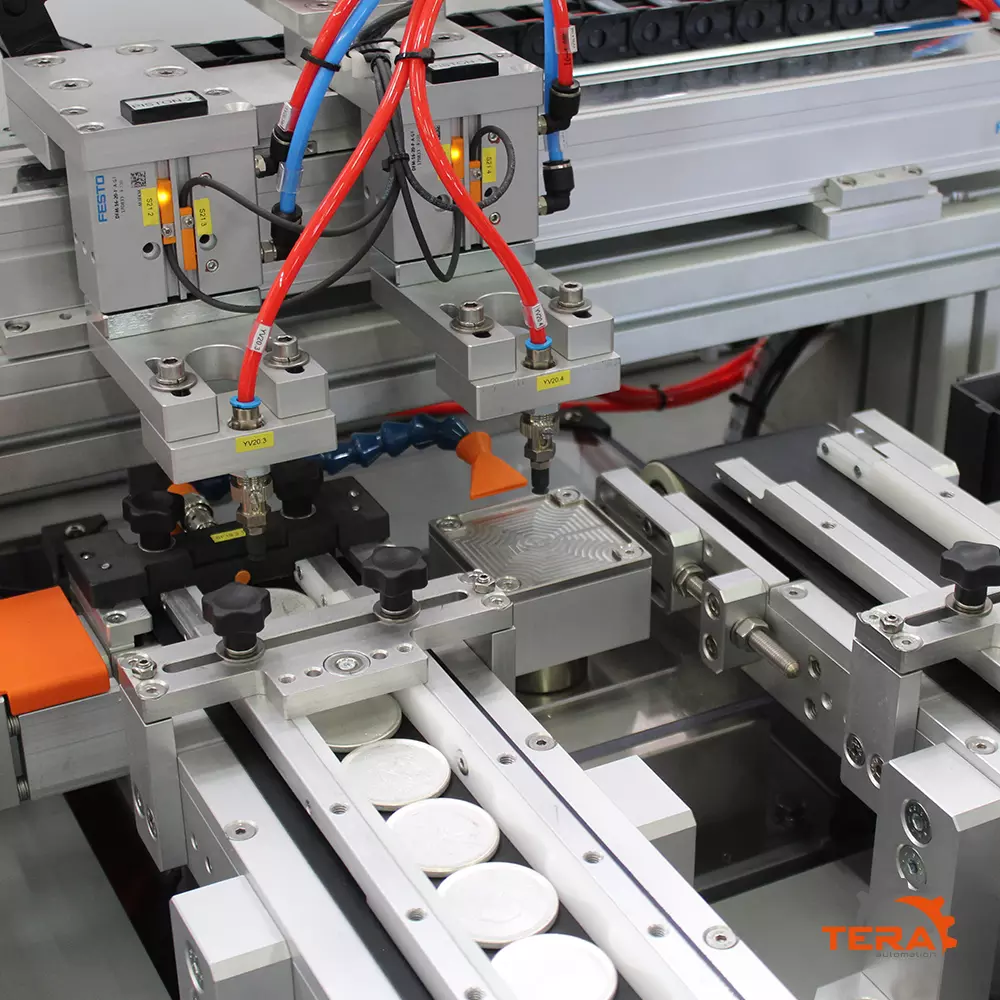

Loading: the operator places the blanks on the machine's left input belt.

03

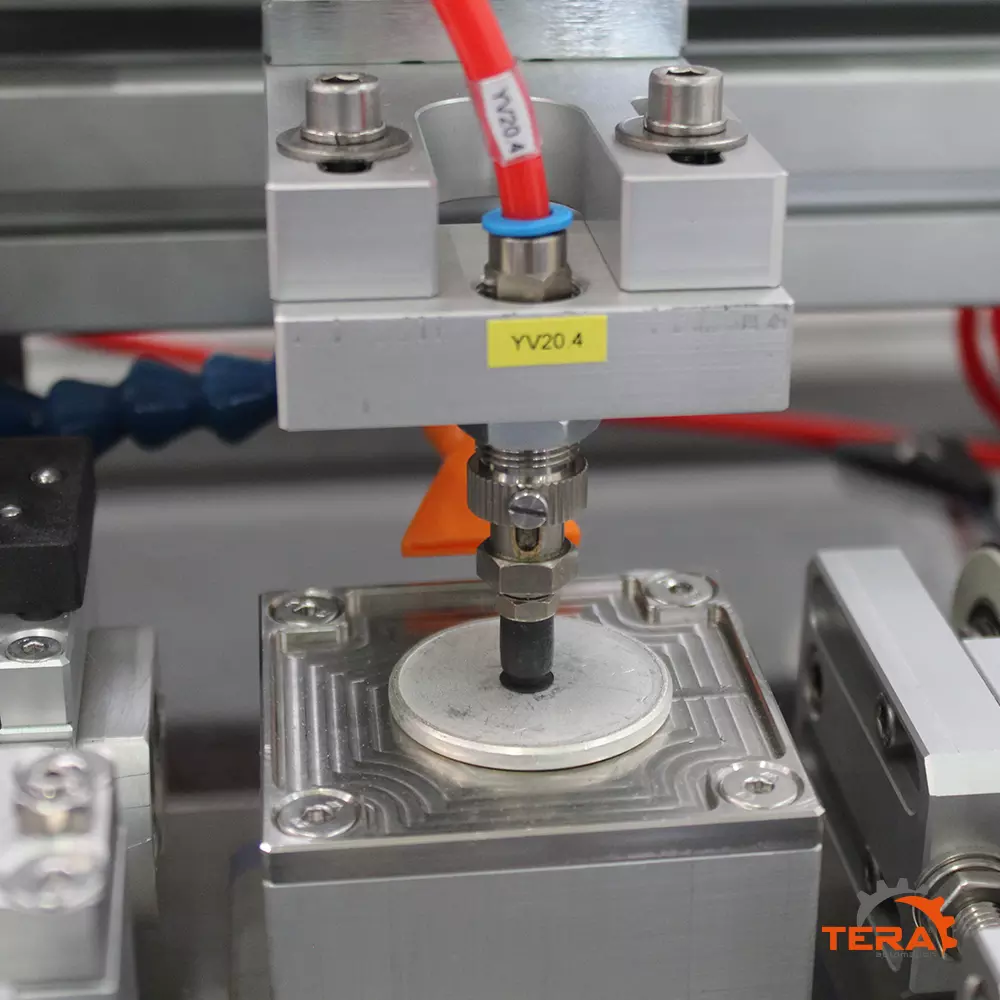

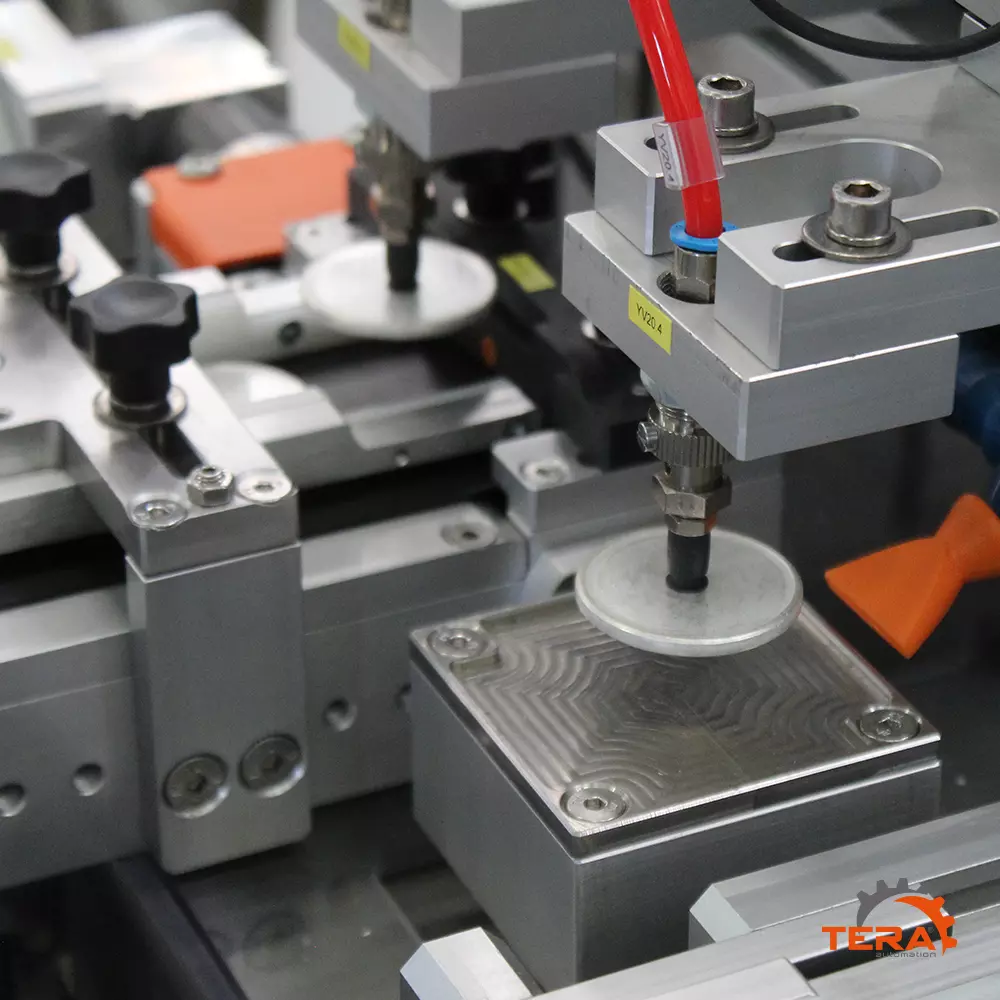

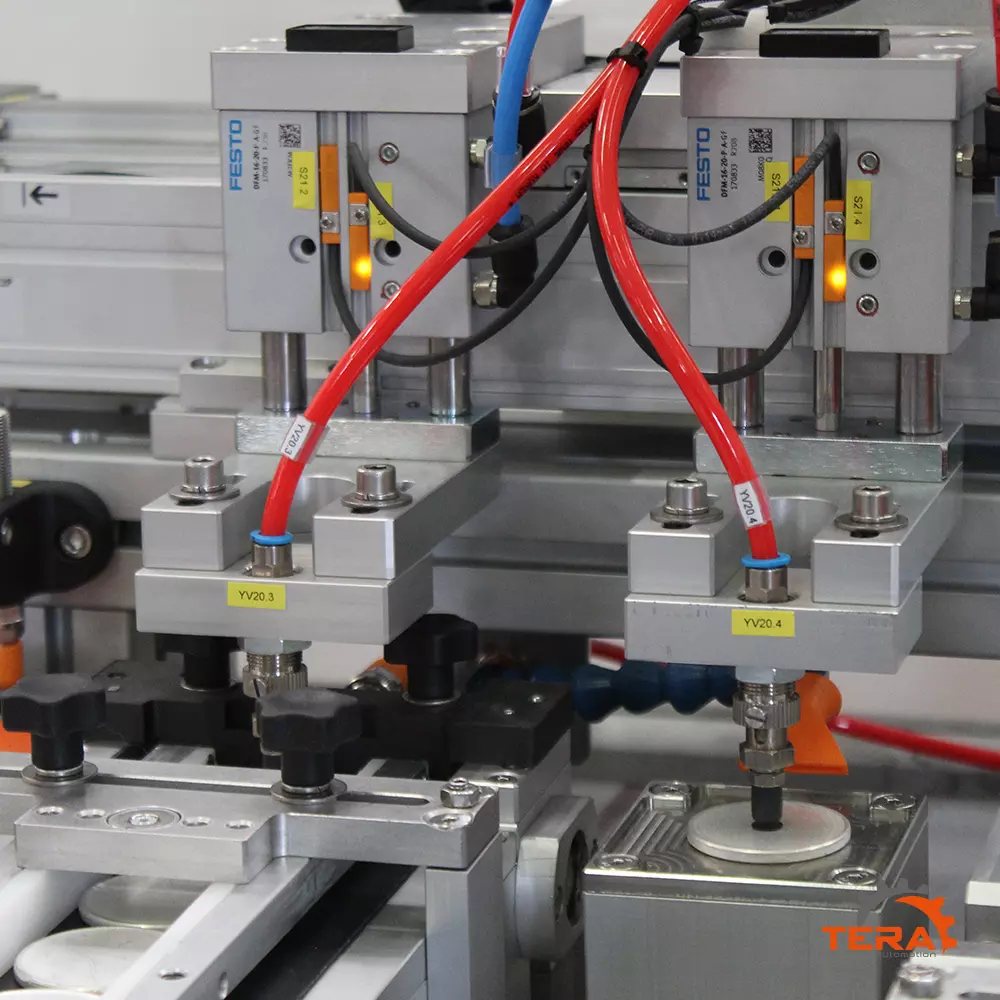

Weighing: the system picks up each blank and places it on a weight measuring cell.

04

Evaluation: the system analyses the detected weight and decides the destination of the blank.

05

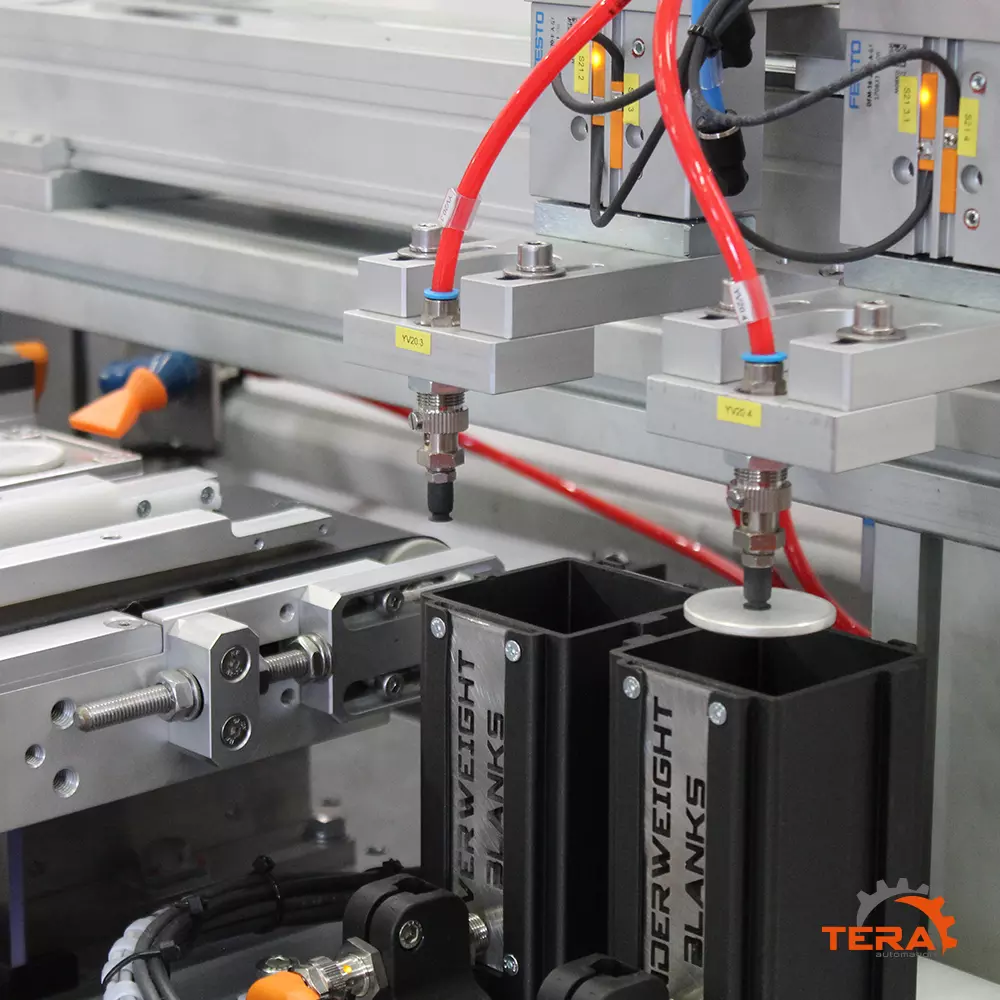

Sorting: if the blank does not conform it is discarded into the underweight or overweight bin. If the blank is compliant it is placed on the outfeed belt.