T-FILL & SEAL

Dosing and packing machine for grains

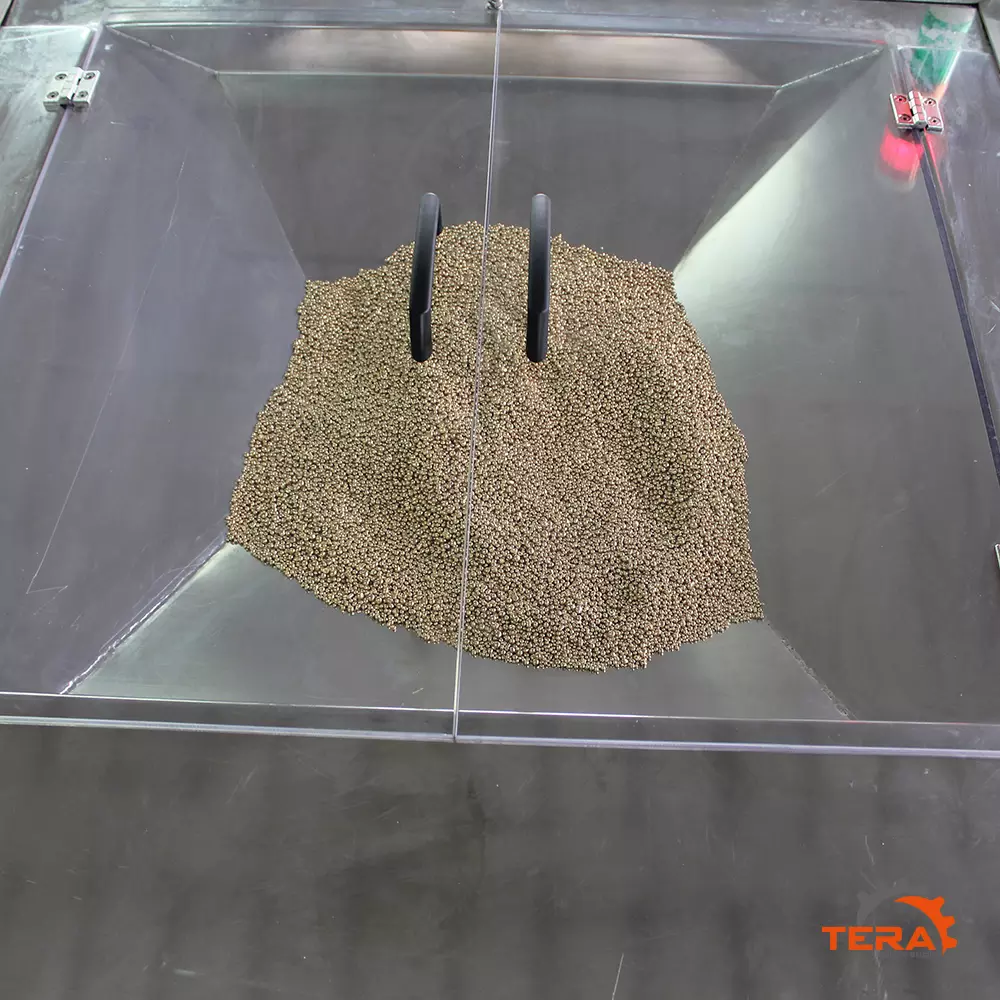

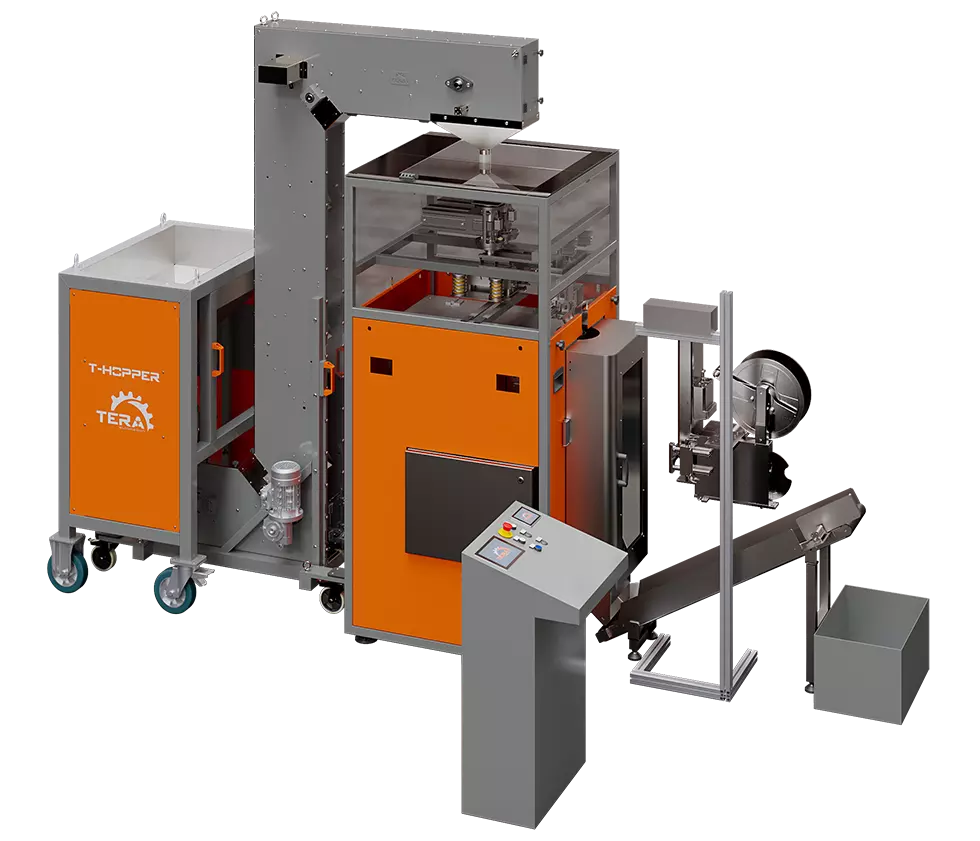

T-Fill&Seal™ is an automated machine that combines the dosing and packaging of metallic granules, optimizing precision and speed. Equipped with an integrated precision load cell and a vertical packaging system, it simplifies a complex process while reducing human error. Thanks to an integrated emptying system, it prevents metal losses and contamination, ensuring effective cost reduction.

T-FILL&SEAL CONSISTS OF:

- Load cell with ± 1g accuracy

- Vertical packaging machine for horizontal sealing

- Pillow packaging

- PLC-HMI interface with full-touch 7.5 inch display to control weighing and sealing operations

- It can be equipped with integrated printers for automated serialization and printing of logo

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Optimisation

Two-in-one dosing and packaging machine with space optimization. Fast, automated and continuous dosing and packaging operations. Automated serialization and printing of logo.

02

Control

Dosing and sealing operations are easily controlled with PLC-HMI. Manufacturing data storage.

03

Efficiency

No material loss or cross-contamination.

MODELS

| Dimensions | 5000 x 4000 x h3500 mm |

| Weight | 2600 Kg |

| Bag max. dimensions | 270 x 200 mm |

| Loading hopper volume | 20 lt |

| Accuracy | +- 1g |

| Grain production per hour | 70/80 pc/h |

| Power | 60 kW |

--

TECHNOLOGY

HOW DOES T-FILL&SEAL MACHINE WORK?

TAILORED AUTOMATION

AUTOMATION FOR PERFECTLY DOSED AND PACKAGED GRAINS

Each Tera Automation machine can be conceived as part of a modular line which can be combined according to the company's needs and facility space. Each machine can be fitted to existing machines and a full line can be developed over time.

T-Fill&Seal™ was designed with the purpose of dosing and packaging grains made of metal or other materials with known weight in a very precise way, and can be combined with other machines, according to each operator's specific needs.