T-ROBOMINT

Automated minting station

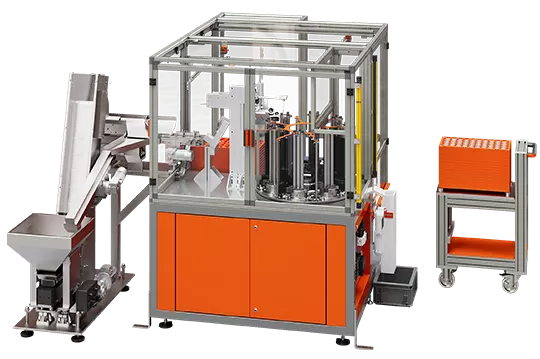

T-Robomint™ is an advanced automation system for refineries and mints, ideal for the continuous production of coins, medals and ingots in different formats.

Using Cartesian axis technology, it transforms manual presses into autonomous machines, reducing the need for direct supervision.

With a rapid change of moulds and components, it guarantees maximum flexibility, uninterrupted production shifts and constant output over time.

Innovative and efficient, T-Robomint™ revolutionises the stamping division.

T-ROBOMINT CONSISTS OF:

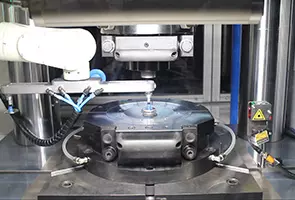

- a loader containing the pieces that need to be minted/stamped;

- an antropomorphic robot with double grippingsystem;

- a working station for the zero adjustment of blanks;

- a tray to collect minted/stamped pieces;

- a touch control panel & PLC.

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Productivity

Increases shifts without interruptions, maintaining a constant yield over time.

02

Flexibility

Easy adaptation to different product formats with a simple change of components.

03

Efficiency

Maximises productivity, reducing downtime and the need for direct supervision.

MODELS

| Dimensions | 2450 x 1380 x h2600 mm |

| Weight | 760 kg |

| Max. absorbed power | 8 kW |

| Production | from 450 pcs/h |

| Integrated robot | Antropomorfic |

--

TECHNOLOGY

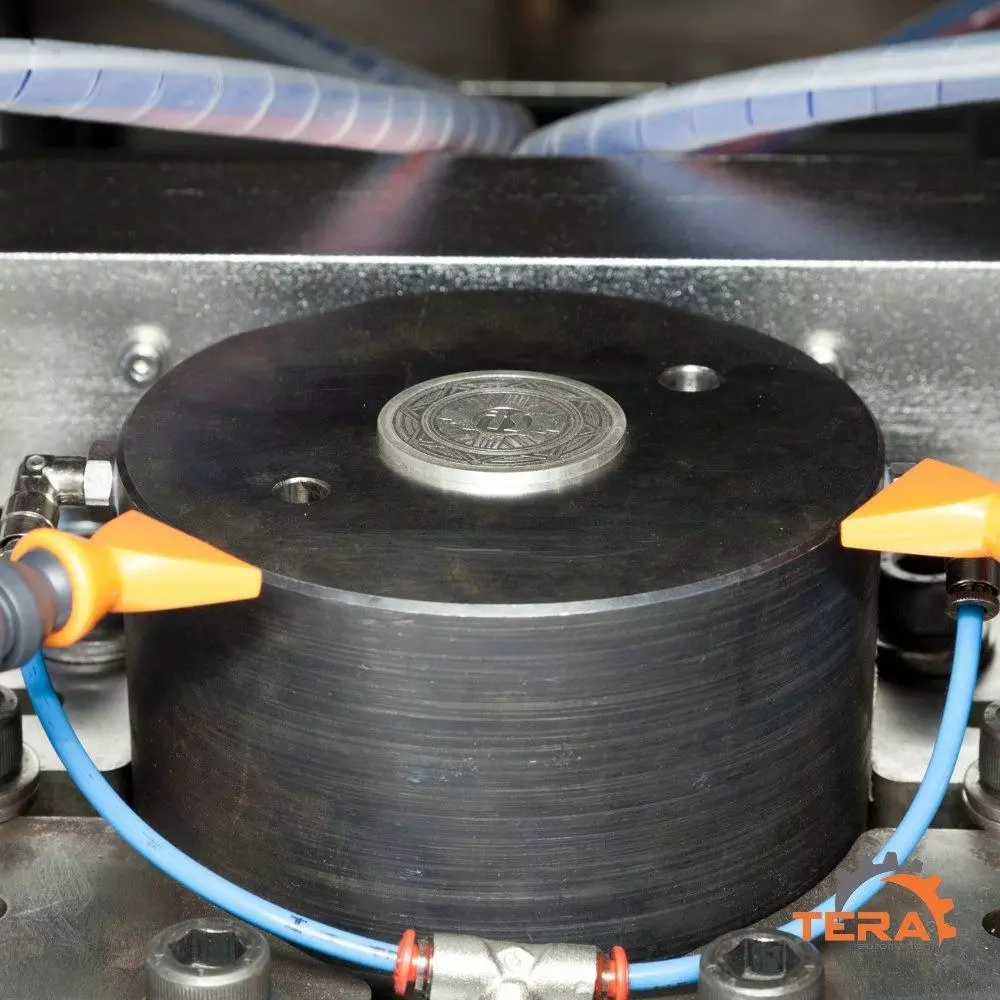

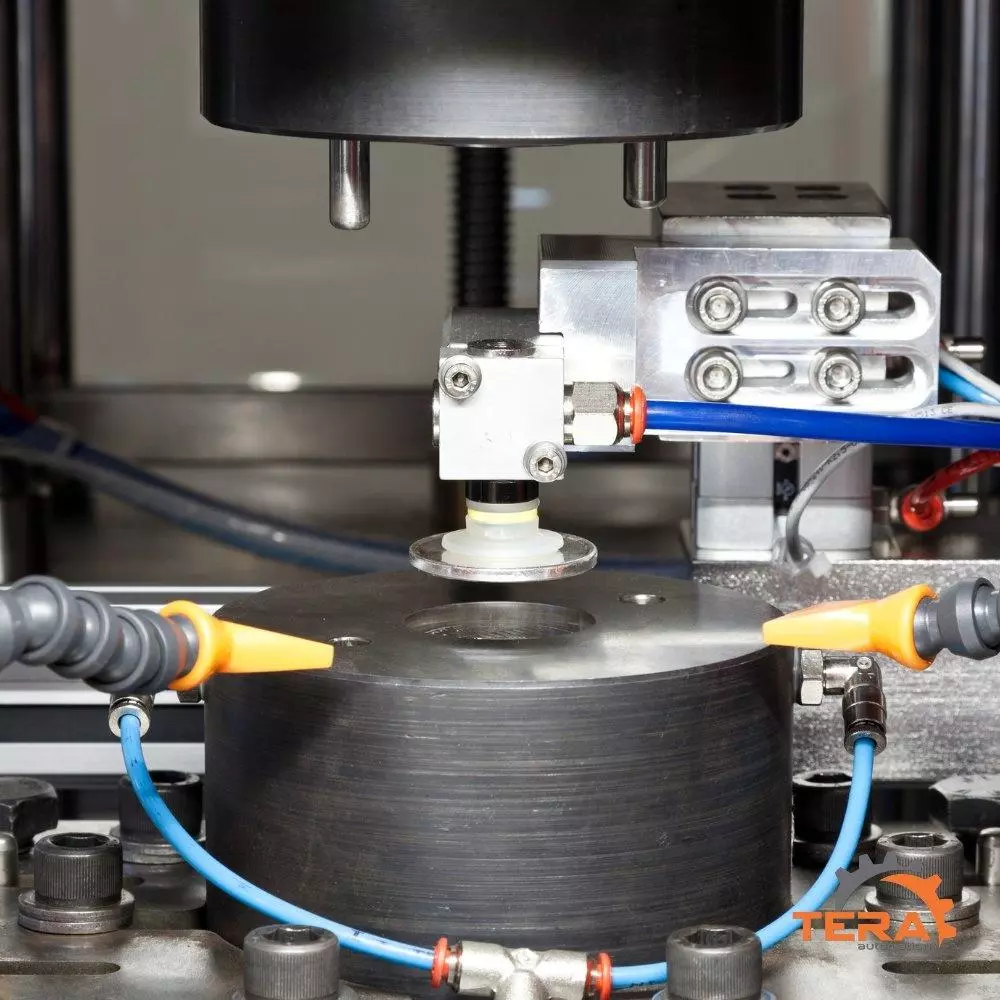

HOW DOES T-ROBOMINT MACHINE WORK?

01

The antropomorphic robot fitted to the T-Robomint™ is provided with two gripping points thus allowing two simultaneous gripping systems: one gripping system moves the blanks from the loader to the press work surface, while the other one grasps the finished product and releases it in the final collection area.

02

Once it has been minted/stamped, the finished product is brought to and released in the collection tray. These trays are not attached to each other, so that the supervisor can collect the trays that are full without needing to interrupt production.