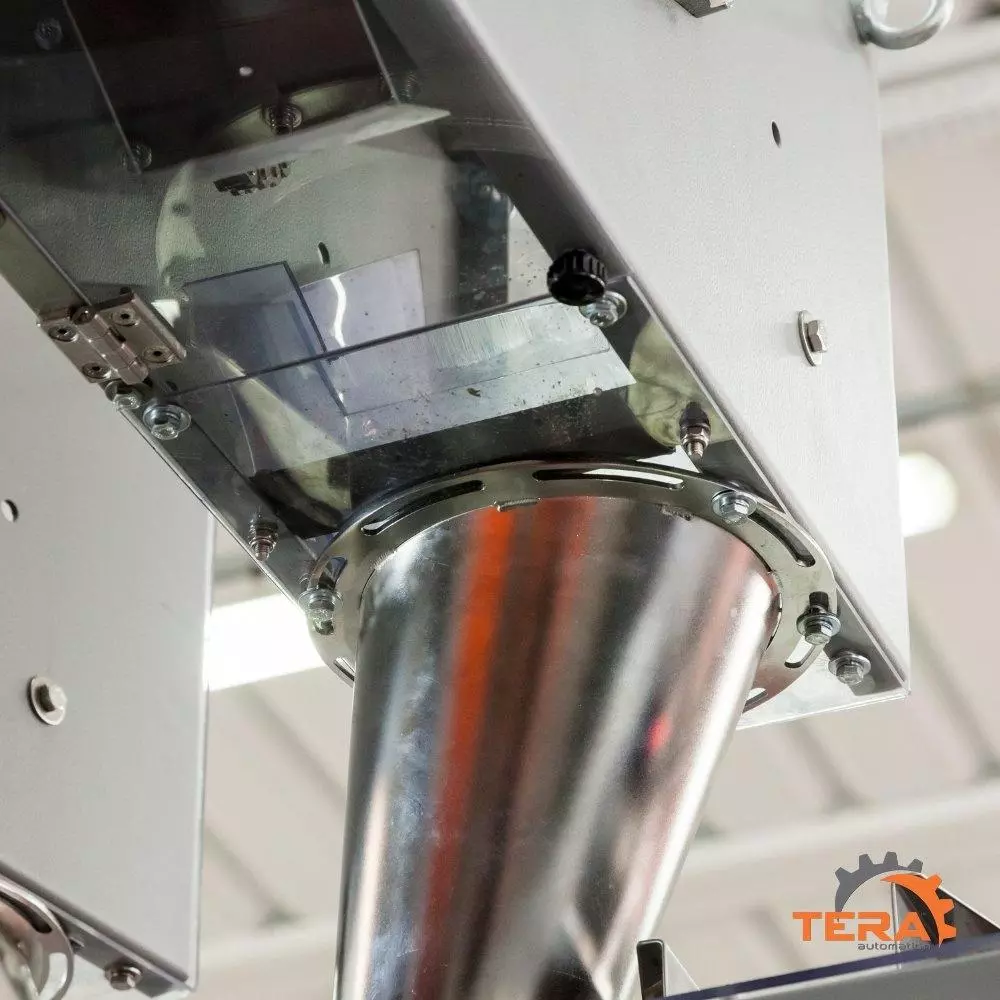

DISCOVER WHICH TERA AUTOMATION MACHINES CAN BE FITTED TO THE T-LIFT™

A CONVEYOR BELT

FOR ANY TYPE OF VERTICAL LOADING

T-Dryray™

Our T-Lift™ bucket conveyor belt can be fitted to the T-Dryray™ machine to carry wet grains from the graining machine to the grain dryer loading channel. A very efficient automated module is thus created, which can be differentiated for two different metals - gold and silver - by installing two T-Lifts™ and two T-Dryrays™.

T-Dosing™

Grains, properly sorted by diameter, are loaded in the respective hoppers by our T-Lift™ bucket conveyor belts. According to the metal type and grain dimension, it is possible to install as many T-Lift™ machines as necessary, up to a maximum of 4 bucket conveyor belts.

T-Fill&Seal™

This very efficient automated module loads the metal grains in the hopper of the dosing and packaging machine called T-Fill&Seal™ using the T-Lift™ bucket conveyor belts.