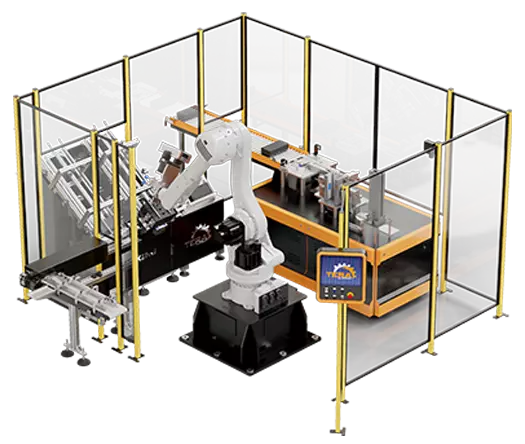

T-BOXING

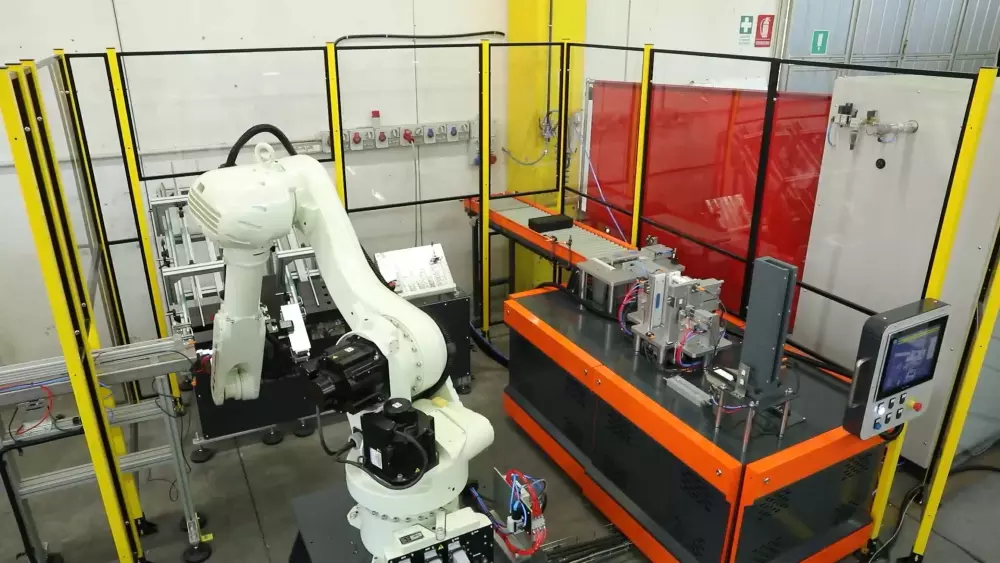

Robotic island for packaging ingots in boxes

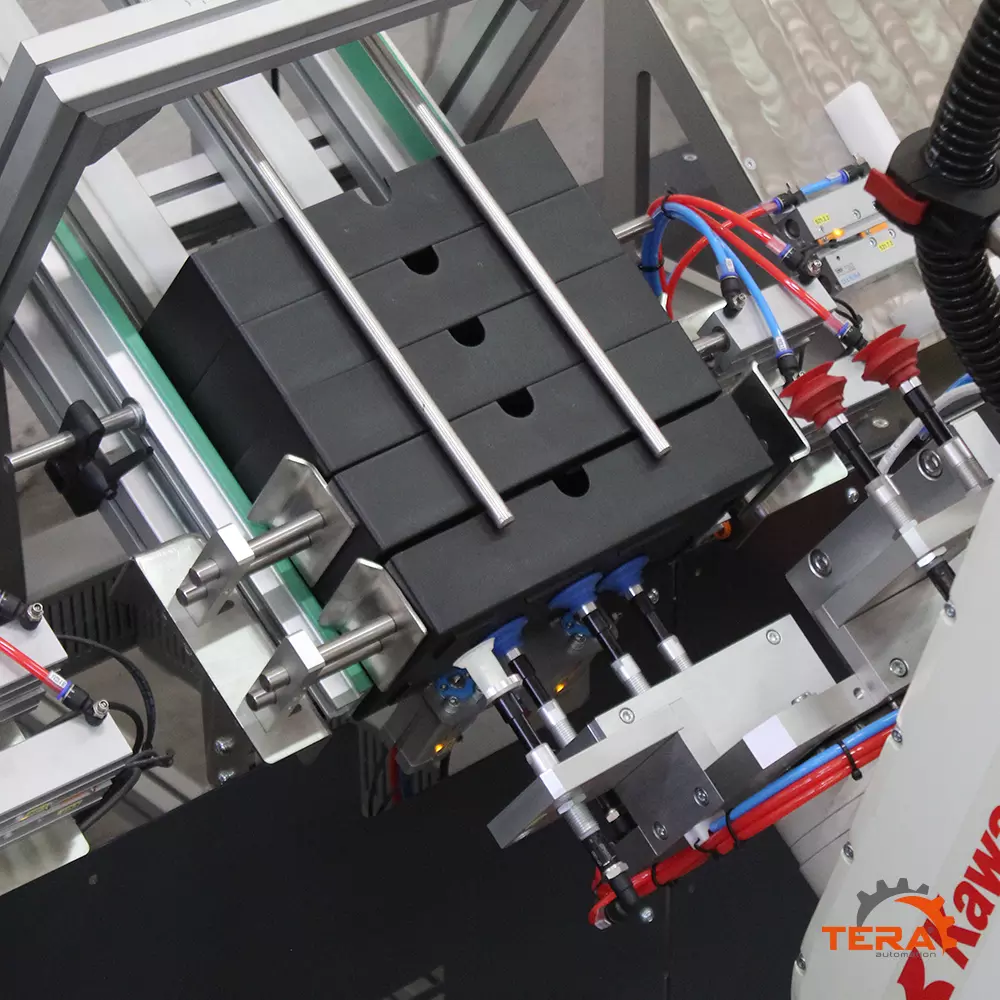

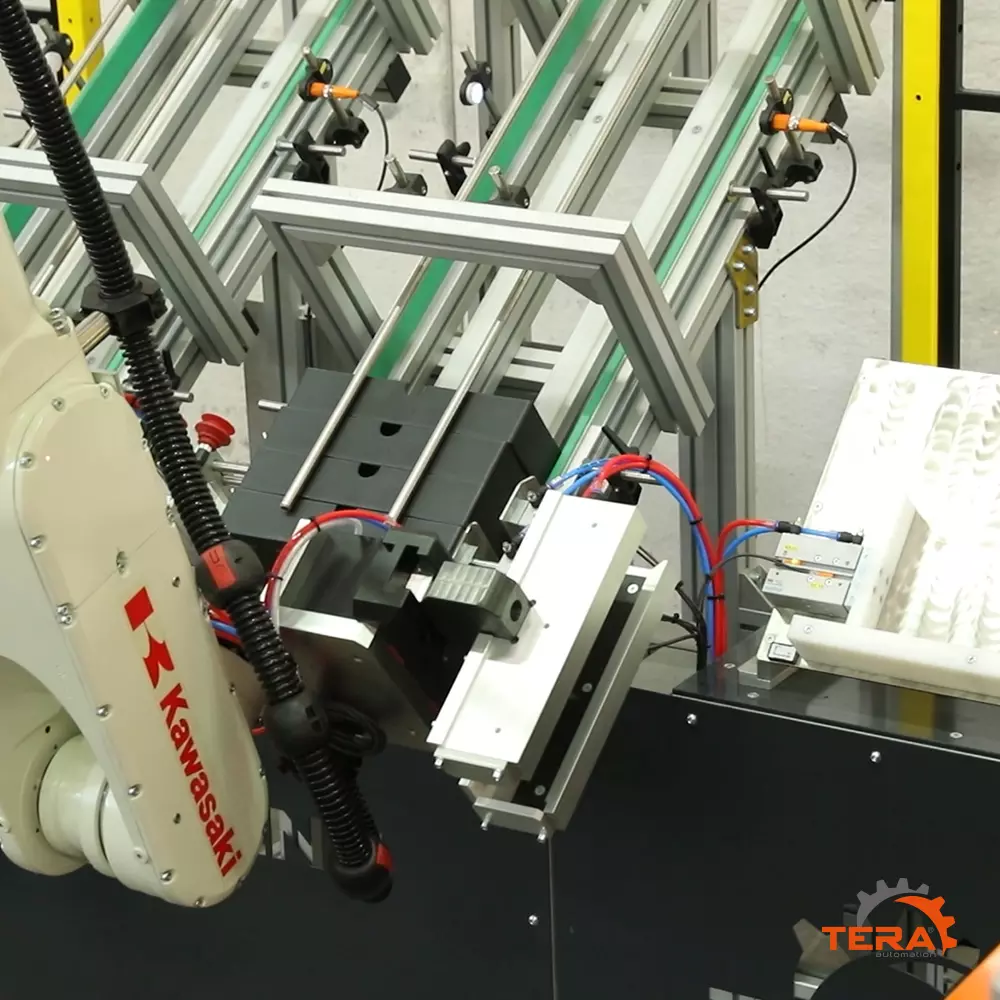

T-Boxing™ is a packaging module for one-kilo ingots. The system consists of a robot that alternately handles ingots, boxes, paper separators, and lids.

T-BOXING CONSISTS OF:

- ingot loading belt

- box loaders

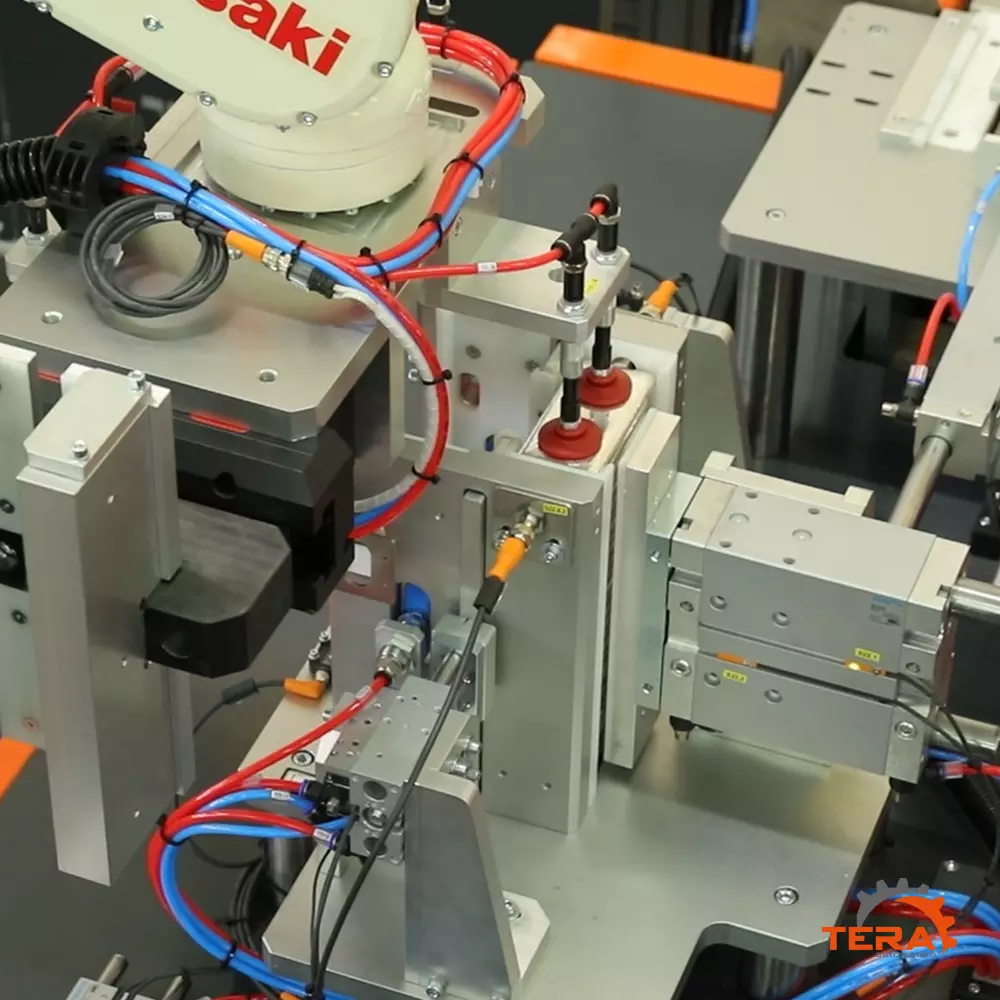

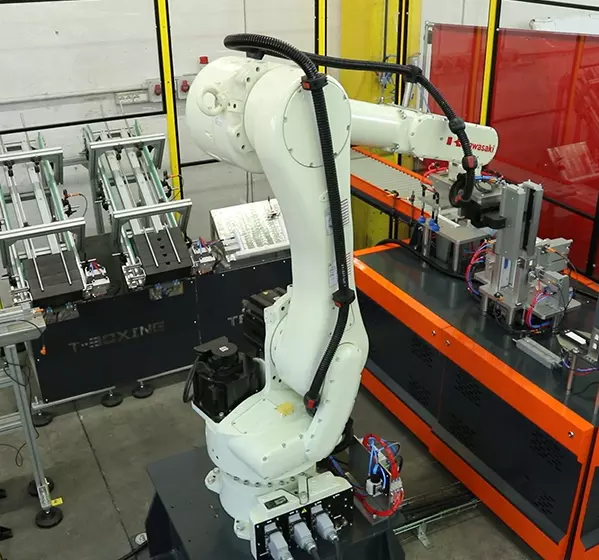

- anthropomorphic robot

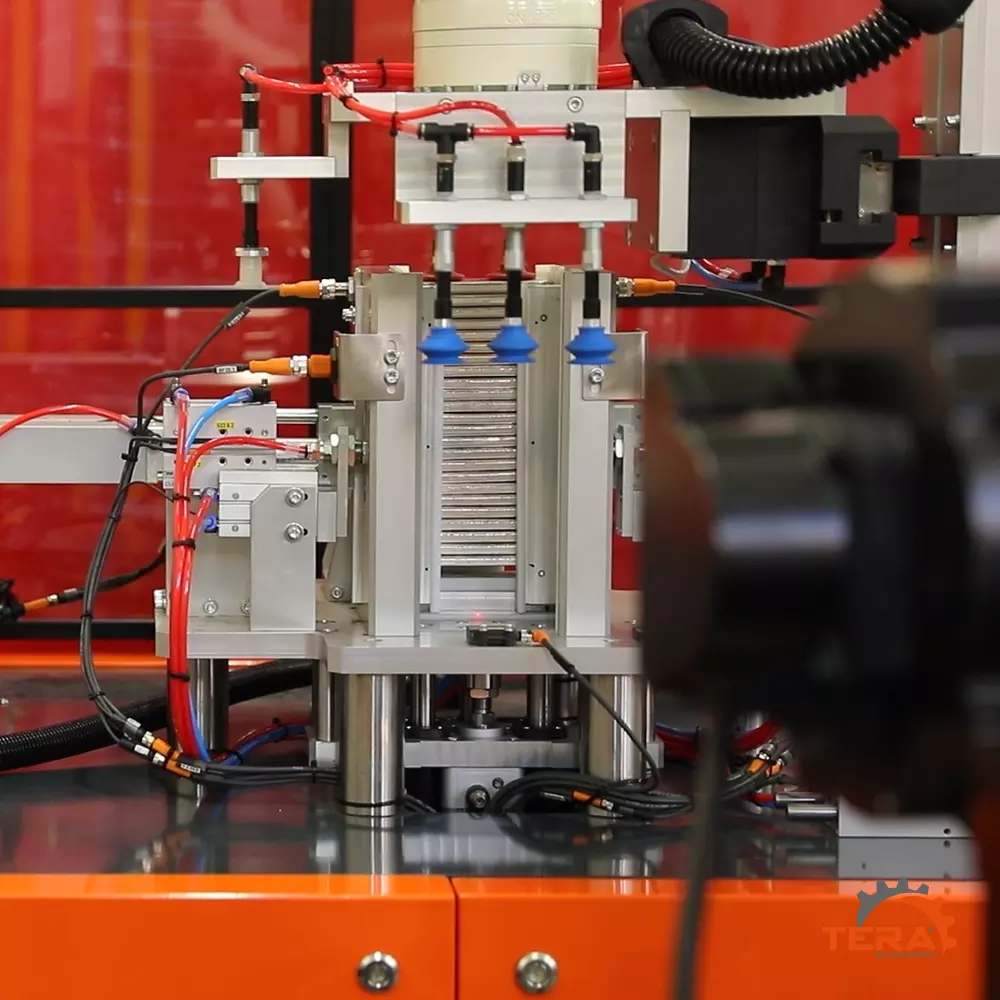

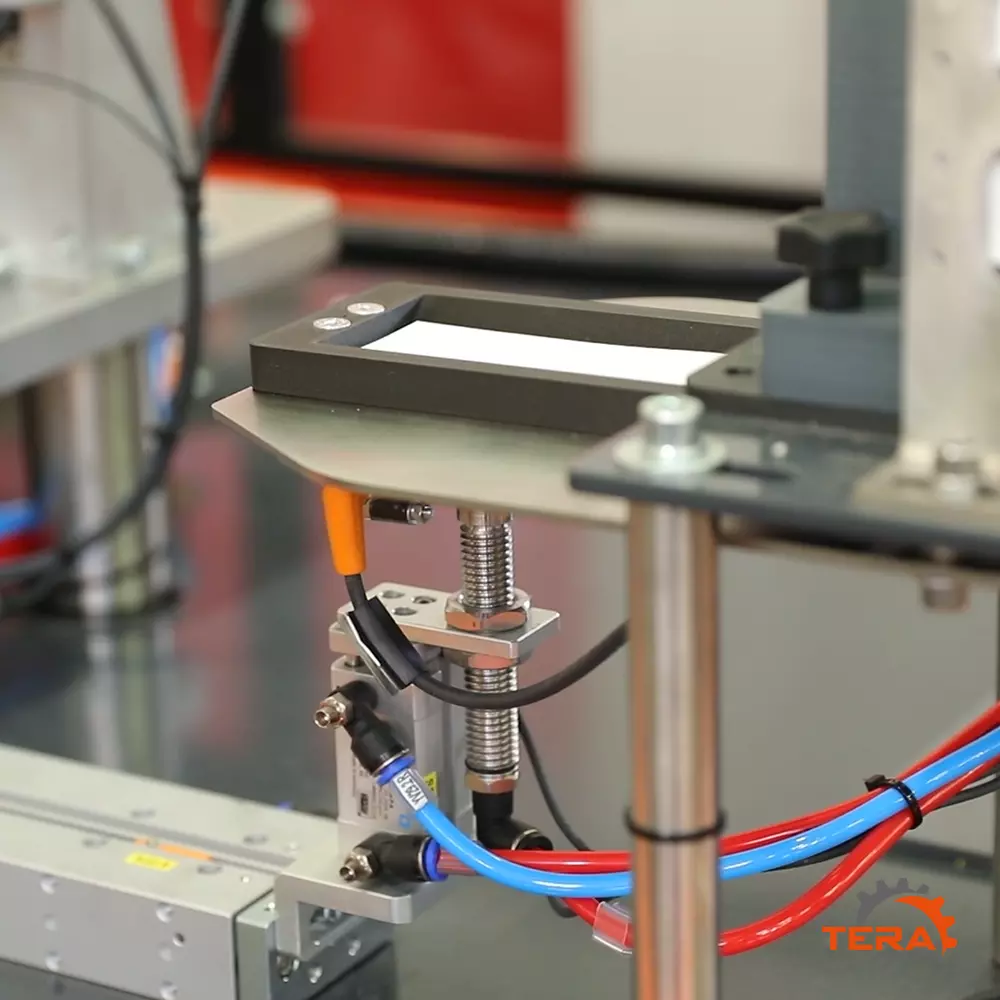

- pack station with card dispenser

- HMI panel

01

Full automation and seamless integration

Thanks to its modular design and the possibility of being integrated into the T-Line, T-Boxing ensures a continuous process from production to final packaging, eliminating downtime and reducing cycle times.

02

Process precision and reliability

The use of a high-performance anthropomorphic robot guarantees precise and synchronized handling, with accurate stacking, automatic labeling, and consistent packaging quality.

03

Ease of use and efficient control

The intuitive HMI allows easy configuration of parameters, real-time line monitoring, and optimization of the packaging cycle, reducing errors and simplifying operational management.

MODELS

|

Box dimensions:

|

280 x 135 x h70 mm |

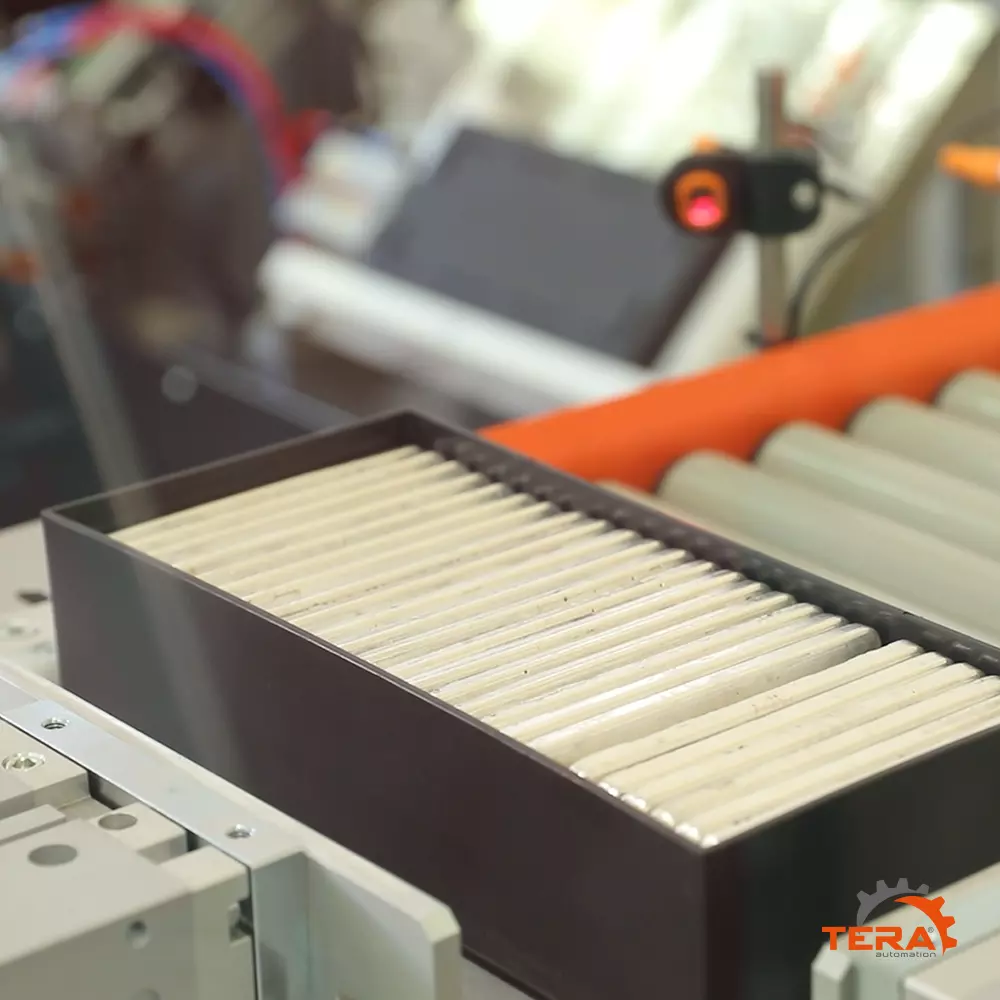

| Separator card dimensions: | 98 x 38 mm |

| Number of ingots per box: | approximately 25 x 1 kg Au (variable depending on the shape of the ingot) |

| Production capacity: | 7 boxes of 25 ingots per hour |

| Box dispenser capacity: | 15-20 |

| Overall dimensions: | 5300 x 3200 x h2300 mm |

| Robot model: | Kawasaki anthropomorphic robot RS080N; reach 2100 mm; playload 80 kg |

| Power supply: | elettrica 400V 10 kW; aria 6 bar |

--

TECHNOLOGY

HOW DOES T-BOXING WORK?

01

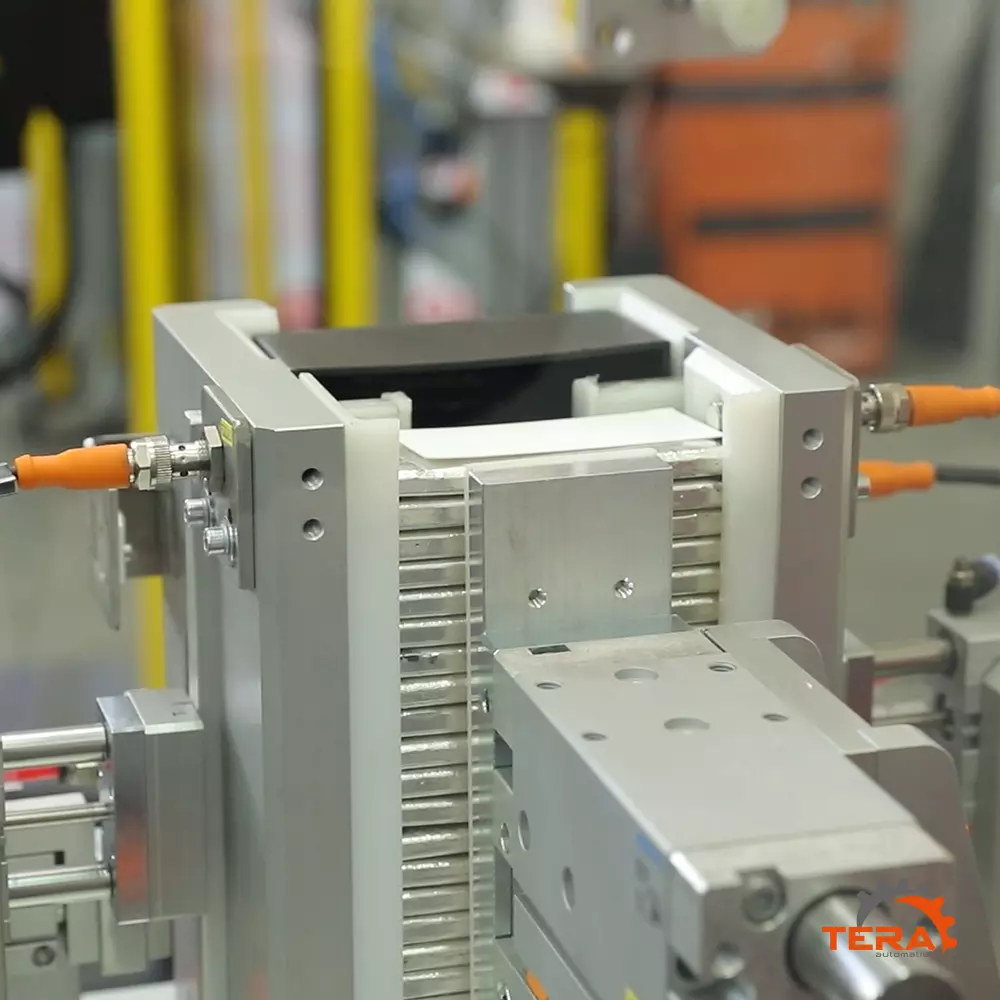

The robot picks up the ingots and stacks them in the ingots collection jig.

02

For each ingot, it alternates a paper separator - dispensed automatically - to prevent abrasion between ingots.

03

The robot then picks up the box base and places the stacked ingots inside.

04

Next, it picks up the lid and closes the filled box that is transferred onto the conveyor belt.