T-WM

Integrated ingot weighing and serialisation system

T-WM™ (Weight and Mark) is an integrated module in which ingots are easily handled using a roller conveyor to position them on the electronic scale and micro-percussion marking machine.

The final weight of the ingot is read from the scale and transferred to the serialisation unit, which applies the corresponding value on the surface of the ingot.

This system is particularly suitable for large format ingots and Good Delivery bars, but can also be used for smaller formats if required.

T-WM CONSISTS OF:

- Roller conveyor belt

- Sartorius GBB14202S-0CE electronic scale, the first scale approved by the LBMA according to the Good Delivery Rules

- T-Numbering™ micro-percussion marking machine

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Efficiency

Total integration into a single weighing and marking machine, reducing processing time and space.

02

Connectivity

Software version designed for the integration of data required by the LBMA; compatibility with the digital platform based on DLT/GBI technology (Gold Bar Integrity Ecosystem); possibility of direct connection to the company's ERP system.

03

Practicality

Ergonomics for the operator in the safe and comfortable handling of heavy bars.

04

Scalability

Possibility of transforming the unit into a fully automated station; integration with handling robots; direct connection to production lines with T-Barmaster furnaces and IT-Onecast system.

MODELS

| Dimensions | 1925x1025xh1710 mm |

| Scale model | Sartorius GBB14202S-0CE |

| Capacity | 12.400 g |

| Precision | 0,01 g |

| T-Numbering model | T-Numering L (marking area of 300x150 mm) |

--

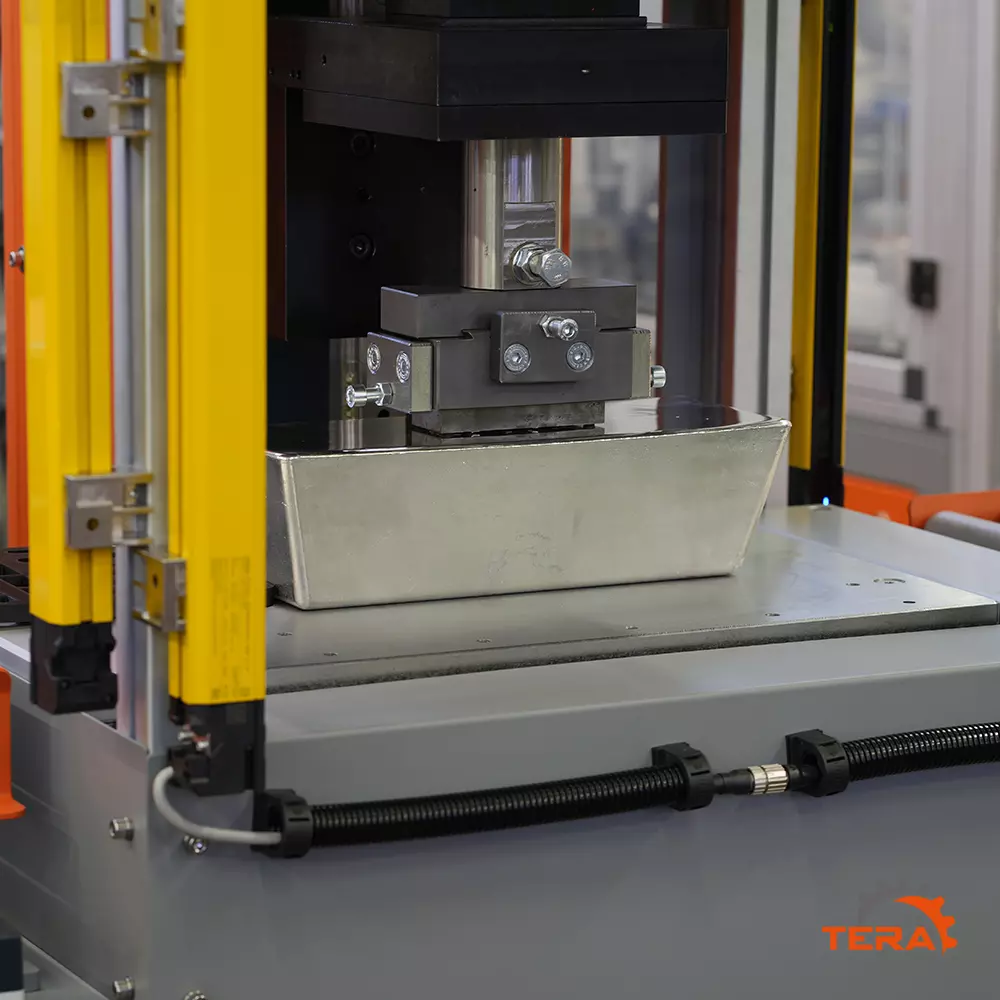

Integrated system consisting of:

- T-Press 33™ hydraulic marking press;

- Sartorius GBB14202S-0CE electronic scale, the first scale approved by the LBMA according to the Good Delivery Rules;

- T-Numbering L™ micro-percussion marking machine.

| Dimensions | 3505x1025xh2350 mm |

| Press model | 33 ton pneumatic-hydraulic press |

| Scale model | Sartorius GBB14202S-0CE |

| Capacity | 12.400 g |

| Precision | 0,01 g |

| T-Numbering model | T-Numering L (marking area of 300x150 mm) |

--

TECHNOLOGY

HOW DOES T-WM™ MACHINE WORK?

01

The operator places the ingot on the roller conveyor. The rolling system helps transfer the bar to the weighing station.

02

The ingot gently reaches the high-precision load cell, on which it is weighed. If the weight conforms, the operator pushes it onto the second roller conveyor and then to the serialisation station.

03

The ingot is placed in a preset position and marked with the T-Numbering™ dot marker.