T-BRUSH

Finishing and brushing ingots

The T-Brush™ machine is designed to automate mirror finish polishing of precious metal ingots.

Our brushing machine is specifically conceived to make sure that operators never touch the brushes. Operators will have to insert the ingots which need to be polished, and extract the polished ones, whenever this task is not carried out by an anthropomorphic robot.

The machine can be set choosing from all its different configurations, according to the size and weight of the ingots that the company wishes to polish.

It is equipped with customizable templates and a set of interchangeable brushes.

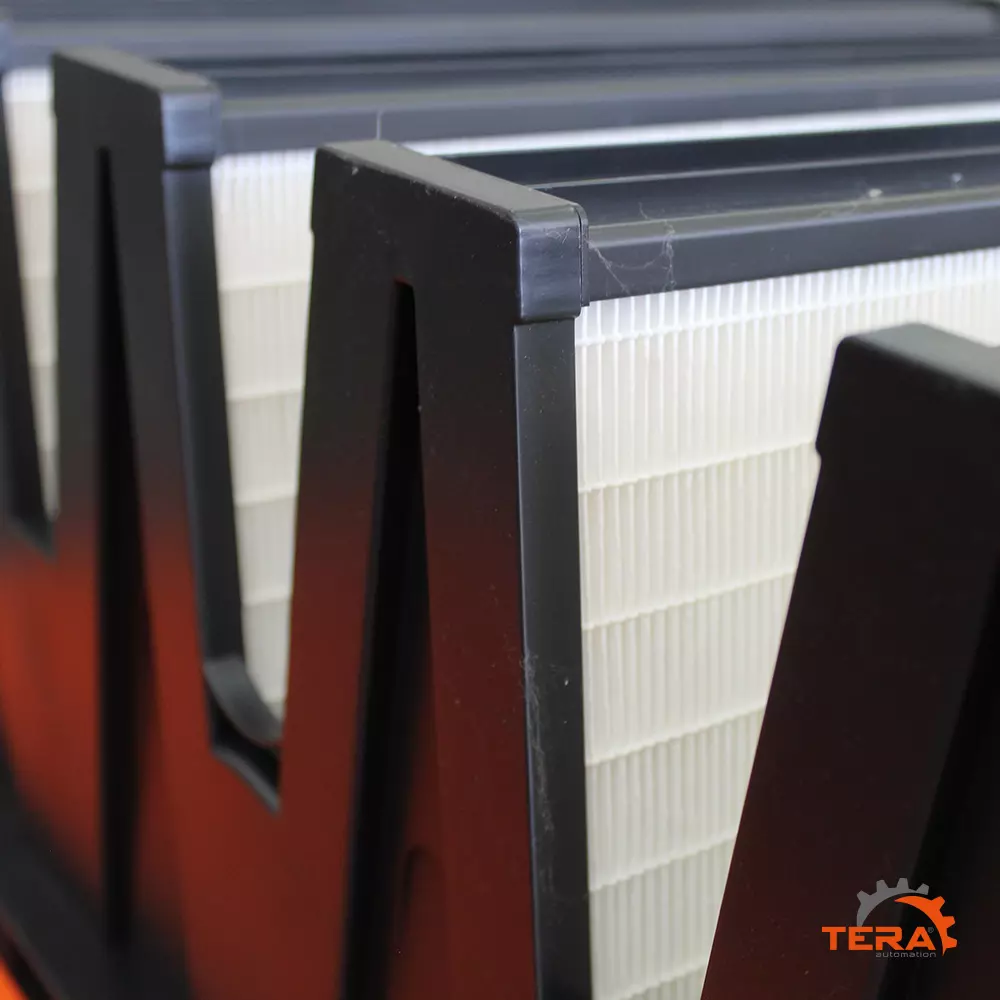

Because the brushing process generates waste, the T-Brush™ brushing machine is fitted with a suction fan which is also extremely useful to keep the working area hygienic and clean.

T-BRUSH CONSISTS OF:

- Control panel

- Suction fan, which is extremely useful to keep the working area hygienic and clean

- Brush unit

- Templates for ingots

- Rotating carousel

- Compressed air gun

ADVANTAGES

THE BENEFITS OF AN INNOVATIVE, AUTOMATED SOLUTION:

01

Quality

Flawless and customizable mirror finish polishing.

02

Optimisation

Operators carry out more qualified tasks. Fast and safe processing.

03

Efficiency

The whole process can be automated. No metal loss.

TECHNOLOGY

HOW DOES T-BRUSH MACHINE WORK?

01

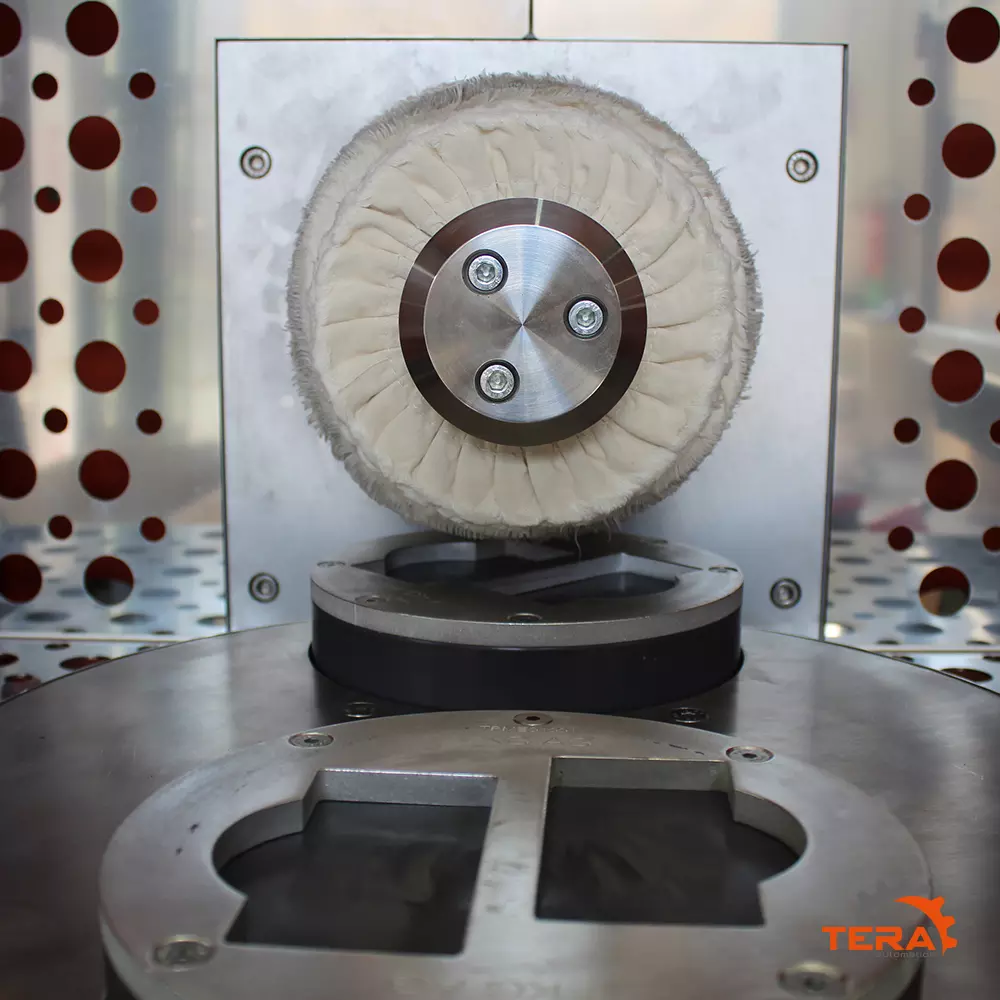

Ingot loading: T-Brush is equipped with two workstations arranged on a rotating table, where templates are placed at a 180° angle: one working inside the machine, the other outside the machine and accessible to the operator. Ingots will be loaded manually.

02

Ingot polishing: above the working template is a rotating brush which remains in place during the polishing action: it is the ingot contained in the template that rises up to be brushed.

03

Ingot discharge and recovery: with a 180° table rotation, the brushed ingot is brought out to be picked up. By means of the same movement, the next ingot to be processed is placed under the brush, thus ensuring continuous production.